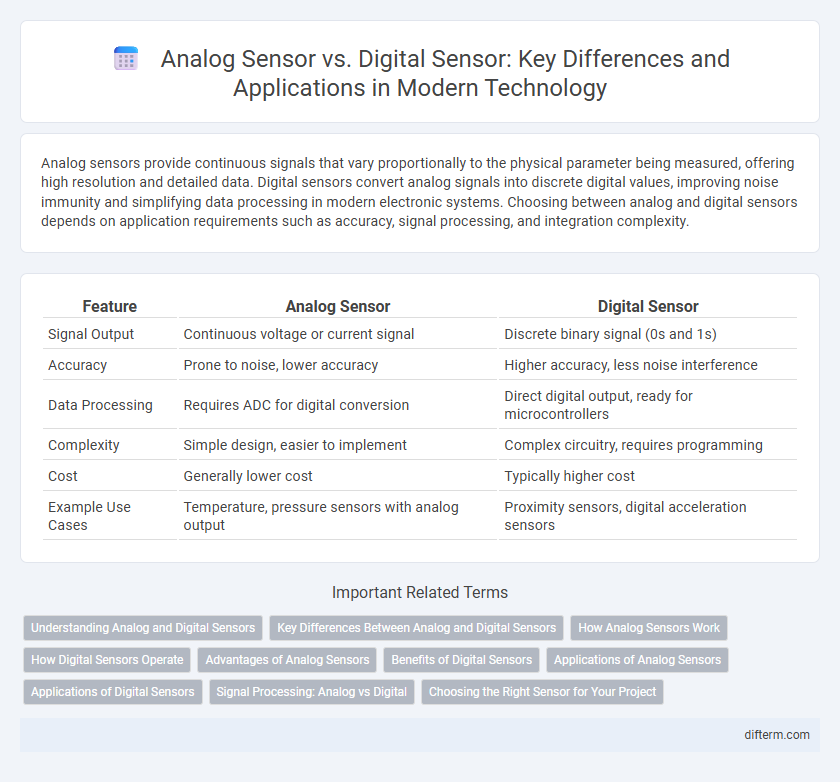

Analog sensors provide continuous signals that vary proportionally to the physical parameter being measured, offering high resolution and detailed data. Digital sensors convert analog signals into discrete digital values, improving noise immunity and simplifying data processing in modern electronic systems. Choosing between analog and digital sensors depends on application requirements such as accuracy, signal processing, and integration complexity.

Table of Comparison

| Feature | Analog Sensor | Digital Sensor |

|---|---|---|

| Signal Output | Continuous voltage or current signal | Discrete binary signal (0s and 1s) |

| Accuracy | Prone to noise, lower accuracy | Higher accuracy, less noise interference |

| Data Processing | Requires ADC for digital conversion | Direct digital output, ready for microcontrollers |

| Complexity | Simple design, easier to implement | Complex circuitry, requires programming |

| Cost | Generally lower cost | Typically higher cost |

| Example Use Cases | Temperature, pressure sensors with analog output | Proximity sensors, digital acceleration sensors |

Understanding Analog and Digital Sensors

Analog sensors measure continuous signals, capturing real-time variations in physical parameters such as temperature, pressure, or light intensity with high resolution. Digital sensors convert these analog signals into discrete digital values, enabling precise data processing and compatibility with microcontrollers and digital systems. Understanding the differences in signal output and data representation between analog and digital sensors is crucial for selecting the appropriate sensor technology in industrial automation and embedded systems.

Key Differences Between Analog and Digital Sensors

Analog sensors detect continuous signals and convert physical phenomena into variable voltage or current output, allowing precise measurement of changes in temperature, light, or pressure. Digital sensors provide discrete, binary output signals (often in pulses or serial data), enabling straightforward integration with microcontrollers and improved noise immunity. Key differences include signal type (continuous vs discrete), output complexity, and processing requirements.

How Analog Sensors Work

Analog sensors detect continuous physical signals, converting variations in parameters like temperature, pressure, or light into proportional electrical signals such as voltage or current. These sensors produce a continuous output that directly corresponds to the magnitude of the measured stimulus, enabling precise and real-time monitoring. Popular analog sensor types include thermocouples, potentiometers, and photoresistors, which rely on physical changes in materials to generate analog signals.

How Digital Sensors Operate

Digital sensors operate by converting the analog input signal into a binary format using an internal analog-to-digital converter (ADC), enabling precise data processing and transmission. They generate discrete digital signals corresponding to specific sensor readings, minimizing noise interference and ensuring high accuracy. This digitized output facilitates seamless integration with microcontrollers and digital systems for real-time monitoring and control.

Advantages of Analog Sensors

Analog sensors provide continuous, real-time data with high resolution, allowing precise measurement of physical quantities such as temperature, pressure, and light intensity. They operate with simple circuitry and typically consume less power compared to digital sensors, making them suitable for low-energy applications. The direct analog signal output enables seamless integration with various signal processing systems without the need for complex conversions.

Benefits of Digital Sensors

Digital sensors provide precise and noise-resistant measurements by converting physical signals into discrete digital values, facilitating seamless integration with microcontrollers and digital systems. Their capability for self-calibration and built-in diagnostics enhances reliability and reduces maintenance requirements. Furthermore, digital sensors enable easier data processing and wireless communication, making them ideal for modern IoT applications and automation systems.

Applications of Analog Sensors

Analog sensors are widely used in temperature monitoring, where precise and continuous voltage output reflects gradual changes in temperature levels, essential for HVAC systems and industrial processes. In automotive applications, analog sensors detect variables like fuel levels and engine temperature to provide real-time feedback for optimal vehicle performance. Medical devices employ analog sensors to measure vital signs such as heart rate and blood pressure, ensuring accurate patient monitoring and diagnostics.

Applications of Digital Sensors

Digital sensors find extensive applications in smart home systems, enabling precise monitoring of temperature, humidity, and motion for automated control and energy efficiency. In healthcare, digital sensors facilitate real-time patient monitoring, enhancing diagnostic accuracy and remote treatment capabilities. Industrial automation relies on digital sensors for high-precision measurements, improving process control, predictive maintenance, and overall operational safety.

Signal Processing: Analog vs Digital

Analog sensors produce continuous signals that represent physical parameters, which require analog-to-digital conversion for digital processing systems. Digital sensors output discrete signals directly, enabling easier integration with microcontrollers and reducing noise interference in signal transmission. Signal processing in digital sensors allows for enhanced accuracy, data compression, and real-time analysis compared to analog signal processing, which relies heavily on filtering and amplification techniques.

Choosing the Right Sensor for Your Project

Selecting the right sensor involves evaluating the specific requirements of your project, such as accuracy, signal processing, and environmental conditions. Analog sensors provide continuous signals ideal for applications needing high resolution and smooth data trends, while digital sensors offer discrete signals that simplify integration with microcontrollers and reduce noise susceptibility. Understanding factors like signal type, interface complexity, and power consumption ensures optimal sensor performance tailored to your technological needs.

Analog sensor vs Digital sensor Infographic

difterm.com

difterm.com