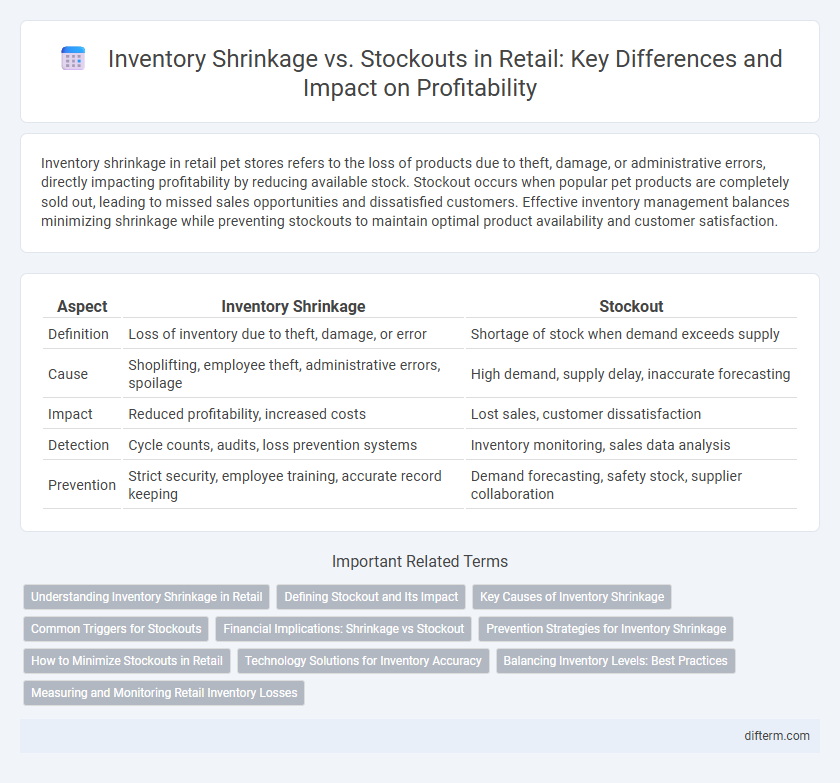

Inventory shrinkage in retail pet stores refers to the loss of products due to theft, damage, or administrative errors, directly impacting profitability by reducing available stock. Stockout occurs when popular pet products are completely sold out, leading to missed sales opportunities and dissatisfied customers. Effective inventory management balances minimizing shrinkage while preventing stockouts to maintain optimal product availability and customer satisfaction.

Table of Comparison

| Aspect | Inventory Shrinkage | Stockout |

|---|---|---|

| Definition | Loss of inventory due to theft, damage, or error | Shortage of stock when demand exceeds supply |

| Cause | Shoplifting, employee theft, administrative errors, spoilage | High demand, supply delay, inaccurate forecasting |

| Impact | Reduced profitability, increased costs | Lost sales, customer dissatisfaction |

| Detection | Cycle counts, audits, loss prevention systems | Inventory monitoring, sales data analysis |

| Prevention | Strict security, employee training, accurate record keeping | Demand forecasting, safety stock, supplier collaboration |

Understanding Inventory Shrinkage in Retail

Inventory shrinkage in retail refers to the loss of products between the point of manufacture or purchase from suppliers and the point of sale, primarily caused by theft, administrative errors, or damage. Unlike stockouts, which occur when inventory levels are insufficient to meet customer demand, shrinkage directly reduces the available stock without an immediate replenishment trigger. Effective shrinkage management involves accurate inventory tracking, loss prevention strategies, and regular audits to minimize financial losses and maintain optimal stock levels.

Defining Stockout and Its Impact

Stockout occurs when demand for a product exceeds available inventory, resulting in lost sales and dissatisfied customers. This inventory issue not only disrupts supply chain efficiency but also negatively affects revenue and brand reputation. Effective stockout management is essential to maintain customer loyalty and optimize retail operations.

Key Causes of Inventory Shrinkage

Inventory shrinkage in retail primarily results from employee theft, shoplifting, administrative errors, and supplier fraud, significantly impacting profit margins. Stockouts, by contrast, often stem from inaccurate demand forecasting and delays in replenishment, disrupting sales and customer satisfaction. Understanding and addressing key causes of inventory shrinkage enables retailers to improve inventory accuracy and reduce losses more effectively.

Common Triggers for Stockouts

Stockouts in retail commonly result from inaccurate demand forecasting, delays in supplier deliveries, and unexpected surges in customer demand. Poor inventory management systems and insufficient safety stock levels further exacerbate stock shortages. Effective monitoring and predictive analytics are essential to minimize these triggers and ensure product availability.

Financial Implications: Shrinkage vs Stockout

Inventory shrinkage leads to direct financial losses due to unaccounted merchandise, reducing overall profit margins and inflating operational costs. Stockouts, however, result in missed sales opportunities and diminished customer loyalty, thereby impacting revenue streams and future market share. Both scenarios require strategic inventory management to balance carrying costs against potential lost income.

Prevention Strategies for Inventory Shrinkage

Inventory shrinkage in retail, caused by theft, damage, and administrative errors, can be minimized through advanced inventory management systems and regular audits. Implementing employee training programs and enhancing security measures like RFID tags and surveillance cameras significantly reduce shrinkage risks. Effective supply chain collaboration and real-time stock monitoring also support early detection and prevention, ensuring accurate inventory levels.

How to Minimize Stockouts in Retail

Effective demand forecasting and real-time inventory tracking play crucial roles in minimizing stockouts in retail, ensuring product availability and customer satisfaction. Implementing automated replenishment systems and maintaining safety stock levels helps retailers respond promptly to fluctuations in consumer demand. Regular audits and integrating point-of-sale (POS) data analytics optimize inventory management by preventing both stockouts and inventory shrinkage.

Technology Solutions for Inventory Accuracy

Advanced inventory management systems leverage real-time data analytics and RFID technology to minimize inventory shrinkage by identifying discrepancies promptly. Automated replenishment alerts and AI-driven demand forecasting reduce stockouts by ensuring optimal stock levels are maintained. Integrating cloud-based inventory platforms enhances accuracy and visibility across retail locations, improving overall supply chain efficiency.

Balancing Inventory Levels: Best Practices

Balancing inventory levels requires retailers to minimize inventory shrinkage caused by theft, damage, or administrative errors while preventing stockouts that result in lost sales and dissatisfied customers. Implementing accurate inventory tracking systems, regular audits, and employee training helps reduce shrinkage, whereas demand forecasting and safety stock calculations ensure adequate stock availability. Optimal inventory management leverages data analytics and technology to maintain this balance, enhancing profitability and customer satisfaction.

Measuring and Monitoring Retail Inventory Losses

Inventory shrinkage represents the loss of stock due to theft, damage, or administrative errors, while stockouts occur when inventory levels fall below customer demand. Accurate measurement of shrinkage and stockouts involves continuous cycle counts, point-of-sale data analysis, and integration of inventory management systems to identify discrepancies and demand patterns. Monitoring these metrics enables retailers to optimize stock levels, reduce financial losses, and improve customer satisfaction by maintaining product availability.

Inventory Shrinkage vs Stockout Infographic

difterm.com

difterm.com