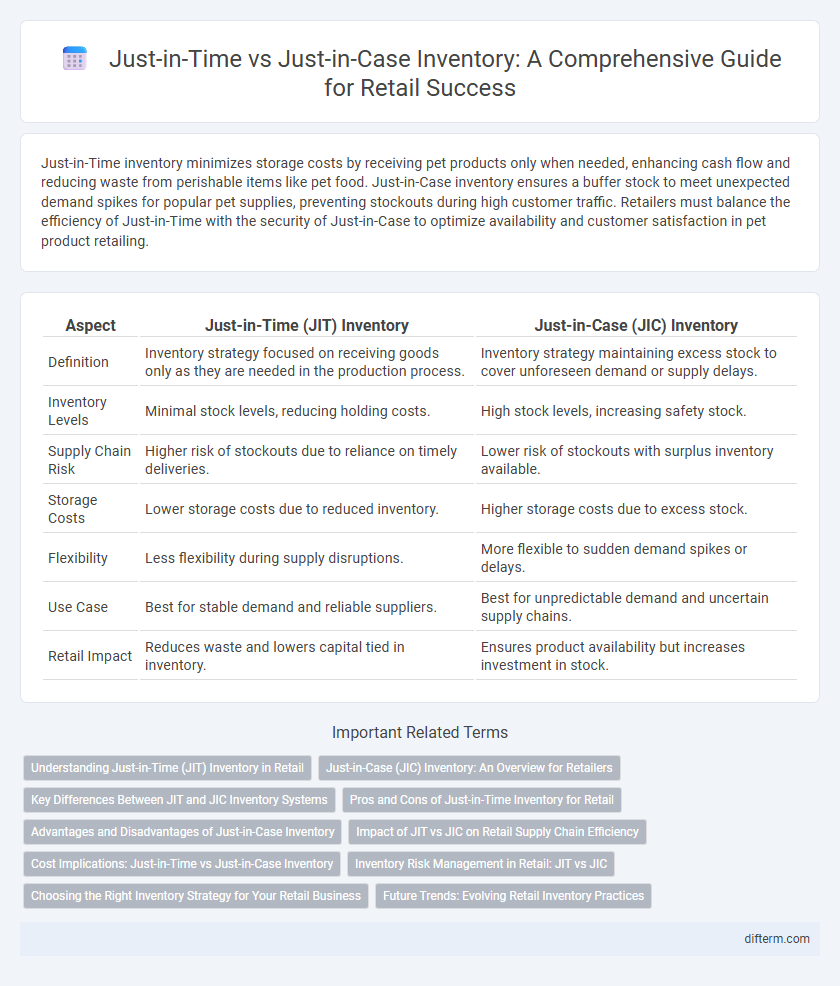

Just-in-Time inventory minimizes storage costs by receiving pet products only when needed, enhancing cash flow and reducing waste from perishable items like pet food. Just-in-Case inventory ensures a buffer stock to meet unexpected demand spikes for popular pet supplies, preventing stockouts during high customer traffic. Retailers must balance the efficiency of Just-in-Time with the security of Just-in-Case to optimize availability and customer satisfaction in pet product retailing.

Table of Comparison

| Aspect | Just-in-Time (JIT) Inventory | Just-in-Case (JIC) Inventory |

|---|---|---|

| Definition | Inventory strategy focused on receiving goods only as they are needed in the production process. | Inventory strategy maintaining excess stock to cover unforeseen demand or supply delays. |

| Inventory Levels | Minimal stock levels, reducing holding costs. | High stock levels, increasing safety stock. |

| Supply Chain Risk | Higher risk of stockouts due to reliance on timely deliveries. | Lower risk of stockouts with surplus inventory available. |

| Storage Costs | Lower storage costs due to reduced inventory. | Higher storage costs due to excess stock. |

| Flexibility | Less flexibility during supply disruptions. | More flexible to sudden demand spikes or delays. |

| Use Case | Best for stable demand and reliable suppliers. | Best for unpredictable demand and uncertain supply chains. |

| Retail Impact | Reduces waste and lowers capital tied in inventory. | Ensures product availability but increases investment in stock. |

Understanding Just-in-Time (JIT) Inventory in Retail

Just-in-Time (JIT) inventory in retail minimizes stock levels by synchronizing product orders precisely with demand, reducing carrying costs and minimizing waste. This strategy relies heavily on accurate demand forecasting and strong supplier relationships to ensure timely delivery and maintain product availability. Retailers implementing JIT gain improved cash flow and operational efficiency by avoiding overstock and responding swiftly to market fluctuations.

Just-in-Case (JIC) Inventory: An Overview for Retailers

Just-in-Case (JIC) inventory in retail involves maintaining higher stock levels to safeguard against supply chain disruptions, ensuring product availability during demand spikes or unforeseen delays. This strategy minimizes stockouts and lost sales by holding extra buffer inventory, though it increases storage costs and risks of obsolescence. Retailers using JIC benefit from enhanced customer satisfaction and operational resilience despite the trade-offs in capital tied up in unsold goods.

Key Differences Between JIT and JIC Inventory Systems

Just-in-Time (JIT) inventory systems focus on minimizing stock levels by receiving goods only as they are needed in the production process, reducing holding costs and waste. Just-in-Case (JIC) inventory systems maintain larger stockpiles to guard against supply chain disruptions, ensuring product availability but increasing storage expenses. Key differences include JIT's emphasis on efficiency and lean operations versus JIC's emphasis on risk mitigation and readiness for demand fluctuations.

Pros and Cons of Just-in-Time Inventory for Retail

Just-in-Time (JIT) inventory in retail reduces holding costs and minimizes excess stock by synchronizing orders with demand, enhancing cash flow and storage efficiency. However, JIT's reliance on precise supplier coordination increases vulnerability to supply chain disruptions, leading to potential stockouts and lost sales. Retailers must balance JIT benefits with risks by ensuring robust supplier relationships and contingency plans to maintain inventory availability.

Advantages and Disadvantages of Just-in-Case Inventory

Just-in-Case Inventory offers the advantage of reducing stockouts and allowing retailers to meet unexpected demand spikes, enhancing customer satisfaction and preventing potential sales loss. However, it involves higher holding costs, increased risk of inventory obsolescence, and requires more warehouse space, impacting overall operational efficiency. Retailers must balance these drawbacks with the benefit of improved supply chain resilience when adopting a Just-in-Case strategy.

Impact of JIT vs JIC on Retail Supply Chain Efficiency

Just-in-Time (JIT) inventory reduces carrying costs and minimizes stock obsolescence in retail supply chains by synchronizing stock replenishment with demand, enhancing operational efficiency and responsiveness. In contrast, Just-in-Case (JIC) inventory prioritizes buffer stock to mitigate supply disruptions, increasing holding costs but ensuring product availability during demand spikes or supplier delays. Retailers leveraging JIT benefit from leaner inventory and faster turnover, while JIC supports reliability in volatile markets, impacting overall supply chain agility and cost structures.

Cost Implications: Just-in-Time vs Just-in-Case Inventory

Just-in-Time (JIT) inventory minimizes holding costs by receiving goods only as needed, reducing storage expenses and capital tied up in stock. Just-in-Case (JIC) inventory increases safety stock levels to prevent stockouts, resulting in higher warehousing costs and potential obsolescence. Retailers must balance JIT's lean cost efficiency against JIC's risk mitigation, considering demand variability and supply chain reliability.

Inventory Risk Management in Retail: JIT vs JIC

Just-in-Time (JIT) inventory in retail minimizes holding costs by receiving goods only as needed, reducing risk exposure from overstock and obsolescence but increasing vulnerability to supply chain disruptions. Just-in-Case (JIC) inventory emphasizes stockpiling goods as a buffer against demand spikes or supplier delays, mitigating stockouts but incurring higher carrying costs and potential waste. Effective inventory risk management balances JIT's lean efficiency with JIC's contingency planning to optimize service levels and operational resilience.

Choosing the Right Inventory Strategy for Your Retail Business

Selecting the right inventory strategy for retail businesses depends on factors like demand variability, supplier reliability, and storage costs. Just-in-Time inventory minimizes holding costs by receiving goods only as needed, improving cash flow but increasing risk of stockouts. Just-in-Case inventory ensures product availability during supply chain disruptions, providing security but increasing carrying expenses and potential obsolescence.

Future Trends: Evolving Retail Inventory Practices

Future retail inventory practices will increasingly integrate Just-in-Time (JIT) systems with advanced AI-driven demand forecasting to reduce overstock and stockouts, enhancing supply chain agility. Just-in-Case (JIC) strategies will evolve by leveraging big data analytics and IoT sensors to maintain optimal buffer stocks, mitigating risks from disruptions such as geopolitical uncertainties and global supply chain constraints. Hybrid models combining JIT efficiency and JIC resilience are expected to dominate, supported by real-time inventory visibility and automated replenishment technologies.

Just-in-Time vs Just-in-Case Inventory Infographic

difterm.com

difterm.com