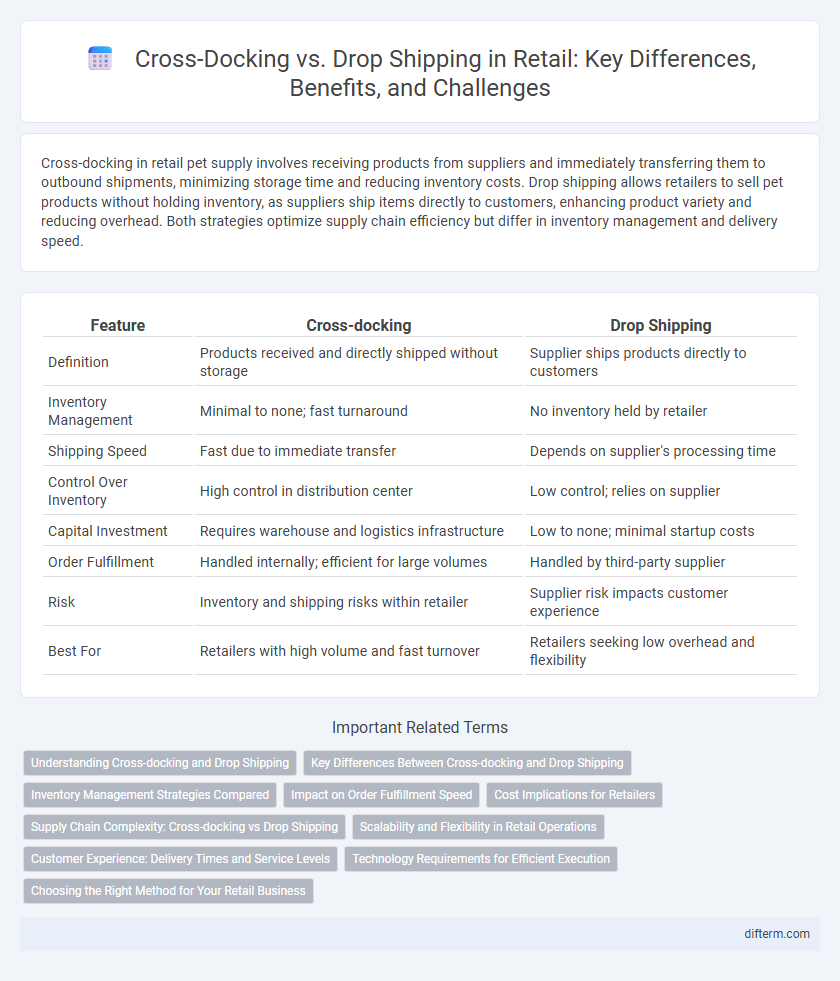

Cross-docking in retail pet supply involves receiving products from suppliers and immediately transferring them to outbound shipments, minimizing storage time and reducing inventory costs. Drop shipping allows retailers to sell pet products without holding inventory, as suppliers ship items directly to customers, enhancing product variety and reducing overhead. Both strategies optimize supply chain efficiency but differ in inventory management and delivery speed.

Table of Comparison

| Feature | Cross-docking | Drop Shipping |

|---|---|---|

| Definition | Products received and directly shipped without storage | Supplier ships products directly to customers |

| Inventory Management | Minimal to none; fast turnaround | No inventory held by retailer |

| Shipping Speed | Fast due to immediate transfer | Depends on supplier's processing time |

| Control Over Inventory | High control in distribution center | Low control; relies on supplier |

| Capital Investment | Requires warehouse and logistics infrastructure | Low to none; minimal startup costs |

| Order Fulfillment | Handled internally; efficient for large volumes | Handled by third-party supplier |

| Risk | Inventory and shipping risks within retailer | Supplier risk impacts customer experience |

| Best For | Retailers with high volume and fast turnover | Retailers seeking low overhead and flexibility |

Understanding Cross-docking and Drop Shipping

Cross-docking streamlines inventory management by directly transferring products from inbound to outbound transportation, minimizing storage time and reducing warehouse costs. Drop shipping eliminates the need for inventory ownership by allowing retailers to fulfill orders through third-party suppliers who ship products directly to customers. Both methods optimize supply chain efficiency but differ in inventory control and fulfillment responsibility, impacting delivery speed and operational costs.

Key Differences Between Cross-docking and Drop Shipping

Cross-docking involves receiving products from suppliers and immediately transferring them to outbound transportation without long-term storage, optimizing inventory turnover and reducing warehouse costs. Drop shipping eliminates the need for physical inventory by having suppliers ship products directly to customers, minimizing retailer fulfillment responsibilities but potentially increasing shipping times. The key differences rest in inventory management, with cross-docking requiring coordination of inbound and outbound logistics, while drop shipping relies heavily on supplier fulfillment and limits retailer control over product availability and delivery speed.

Inventory Management Strategies Compared

Cross-docking minimizes inventory holding by transferring products directly from inbound to outbound shipping, reducing storage costs and improving supply chain efficiency. Drop shipping eliminates inventory management by relying on third-party suppliers to fulfill orders, which lowers capital investment but may increase lead times and reduce control over stock availability. Retailers must weigh cross-docking's rapid turnover and inventory control benefits against drop shipping's flexibility and reduced inventory risks to optimize their supply chain strategies.

Impact on Order Fulfillment Speed

Cross-docking significantly reduces order fulfillment speed by minimizing storage time and enabling direct transfer from inbound to outbound transportation, often completing the process within hours. Drop shipping, while eliminating inventory holding, can increase fulfillment time due to dependence on supplier processing and shipping schedules. Retailers prioritizing rapid delivery often favor cross-docking to streamline logistics and enhance customer satisfaction.

Cost Implications for Retailers

Cross-docking minimizes storage costs by rapidly transferring products from inbound to outbound trucks, reducing warehousing expenses and inventory holding costs for retailers. Drop shipping eliminates inventory investment and associated storage fees entirely but often leads to higher per-unit product costs and potentially increased shipping charges. Retailers must balance lower direct warehousing expenditures in cross-docking with variable supplier costs in drop shipping to optimize overall cost efficiency.

Supply Chain Complexity: Cross-docking vs Drop Shipping

Cross-docking streamlines supply chain operations by minimizing inventory holding and reducing handling time, enhancing efficiency in warehouses and distribution centers. Drop shipping eliminates the need for physical inventory management by shipping products directly from suppliers to customers, which simplifies fulfillment but can introduce challenges in supplier coordination and delivery reliability. Both models impact supply chain complexity differently, with cross-docking requiring robust logistics synchronization and drop shipping relying heavily on supplier performance and real-time data integration.

Scalability and Flexibility in Retail Operations

Cross-docking enhances scalability by enabling rapid turnover of inventory without long-term storage, allowing retailers to handle high order volumes efficiently. Drop shipping offers flexibility by eliminating the need for inventory management, permitting easy expansion into new product categories and markets without upfront investment. Retailers balancing cross-docking and drop shipping can optimize operational agility and scale based on fluctuating consumer demand and supply chain constraints.

Customer Experience: Delivery Times and Service Levels

Cross-docking streamlines inventory handling by transferring products directly from inbound to outbound shipping, significantly reducing delivery times and improving service levels through faster order fulfillment. Drop shipping eliminates the need for retail inventory by shipping products directly from suppliers to customers, but it can introduce variability in delivery times and less control over service quality. Customers often experience quicker, more reliable deliveries with cross-docking, while drop shipping may lead to longer wait times and inconsistent service levels depending on supplier performance.

Technology Requirements for Efficient Execution

Efficient cross-docking demands advanced warehouse management systems (WMS) and real-time inventory tracking software to synchronize inbound and outbound shipments, minimizing storage time and reducing handling costs. Drop shipping relies heavily on integrated e-commerce platforms and electronic data interchange (EDI) to ensure seamless order transmission from retailers to suppliers, enhancing order accuracy and customer satisfaction. Both methods benefit from automation technologies like barcode scanning and IoT sensors to optimize order fulfillment speed and accuracy within retail supply chains.

Choosing the Right Method for Your Retail Business

Selecting between cross-docking and drop shipping depends on inventory control preferences and delivery speed requirements in retail. Cross-docking minimizes storage costs by transferring products directly from inbound to outbound shipping, ideal for fast-moving goods and high-volume retailers. Drop shipping eliminates inventory holding by shipping products directly from suppliers to customers, suitable for businesses seeking low upfront investment and diverse product offerings.

Cross-docking vs Drop Shipping Infographic

difterm.com

difterm.com