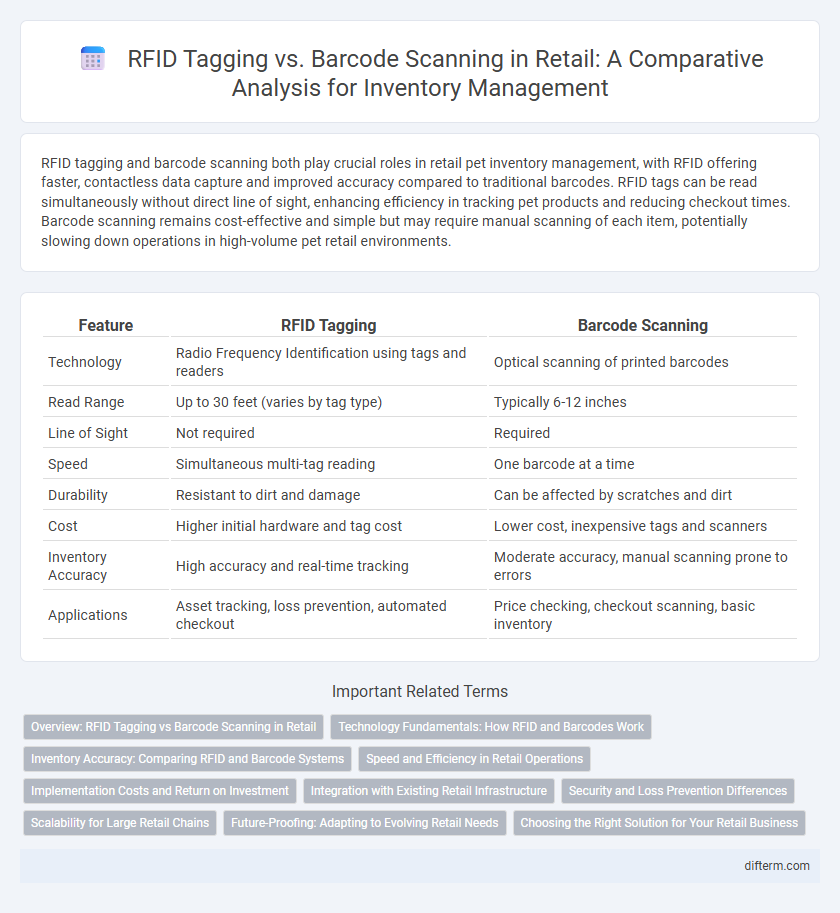

RFID tagging and barcode scanning both play crucial roles in retail pet inventory management, with RFID offering faster, contactless data capture and improved accuracy compared to traditional barcodes. RFID tags can be read simultaneously without direct line of sight, enhancing efficiency in tracking pet products and reducing checkout times. Barcode scanning remains cost-effective and simple but may require manual scanning of each item, potentially slowing down operations in high-volume pet retail environments.

Table of Comparison

| Feature | RFID Tagging | Barcode Scanning |

|---|---|---|

| Technology | Radio Frequency Identification using tags and readers | Optical scanning of printed barcodes |

| Read Range | Up to 30 feet (varies by tag type) | Typically 6-12 inches |

| Line of Sight | Not required | Required |

| Speed | Simultaneous multi-tag reading | One barcode at a time |

| Durability | Resistant to dirt and damage | Can be affected by scratches and dirt |

| Cost | Higher initial hardware and tag cost | Lower cost, inexpensive tags and scanners |

| Inventory Accuracy | High accuracy and real-time tracking | Moderate accuracy, manual scanning prone to errors |

| Applications | Asset tracking, loss prevention, automated checkout | Price checking, checkout scanning, basic inventory |

Overview: RFID Tagging vs Barcode Scanning in Retail

RFID tagging enables retailers to track inventory in real-time using radio frequency identification, offering faster and more accurate data collection than barcode scanning, which requires line-of-sight scanning. RFID tags can store more data and withstand harsh environments, making them ideal for complex supply chains, whereas barcodes are cost-effective and widely used for basic item identification. Retailers leveraging RFID benefit from improved stock visibility and reduced shrinkage, while barcode systems remain a reliable solution for straightforward checkout and inventory tasks.

Technology Fundamentals: How RFID and Barcodes Work

RFID tagging uses radio frequency signals to automatically identify and track tags attached to products, enabling non-line-of-sight and bulk scanning capabilities, while barcode scanning relies on optical recognition of printed patterns that require line-of-sight alignment with a scanner. RFID systems consist of a tag with a microchip and antenna, and a reader that emits radio waves to communicate data, whereas barcode systems involve a visible code scanned by laser or camera-based readers translating visual information into digital data. The efficiency of RFID in real-time inventory management and faster data capture contrasts with barcodes' lower cost and simplicity, highlighting fundamental differences in technology architecture and operational performance.

Inventory Accuracy: Comparing RFID and Barcode Systems

RFID tagging offers significantly higher inventory accuracy compared to barcode scanning due to its ability to read multiple items simultaneously without line-of-sight requirements, reducing human error during stock counts. Barcode scanning relies on manual scanning processes that can lead to misreads or missed items, often resulting in inventory discrepancies. Retailers implementing RFID systems report inventory accuracy improvements exceeding 95%, which enhances stock management efficiency and reduces out-of-stock scenarios.

Speed and Efficiency in Retail Operations

RFID tagging significantly enhances speed and efficiency in retail operations by enabling wireless, simultaneous scanning of multiple items without line-of-sight, reducing checkout times and inventory management delays. Barcode scanning, while cost-effective and widely used, requires individual item scanning and direct visibility, which can slow down processes during peak hours or large inventories. Retailers adopting RFID technology experience improved stock accuracy and faster replenishment cycles, boosting overall operational productivity.

Implementation Costs and Return on Investment

RFID tagging involves higher initial implementation costs due to the need for specialized readers, tags, and integration with inventory systems, while barcode scanning requires lower upfront investment with widely available hardware. Despite the greater initial expense, RFID offers faster inventory tracking, reduced labor costs, and enhanced accuracy, driving a stronger return on investment over time. Retailers adopting RFID report improved supply chain efficiency and shrinkage reduction, often achieving ROI within 12 to 18 months compared to longer periods for barcode systems.

Integration with Existing Retail Infrastructure

RFID tagging offers seamless integration with existing retail infrastructure by enabling real-time inventory tracking and automated data collection without line-of-sight scanning, which enhances operational efficiency compared to traditional barcode scanning. Retailers can retrofit RFID readers alongside current barcode systems, facilitating a gradual technology transition and minimizing disruption to store logistics. The use of RFID also supports advanced analytics and omnichannel fulfillment, leveraging existing point-of-sale and inventory management systems for improved accuracy and speed.

Security and Loss Prevention Differences

RFID tagging offers enhanced security in retail by enabling real-time inventory tracking and reducing theft through automated alerts when items leave designated zones, unlike barcode scanning which requires line-of-sight and manual scanning. RFID technology's encrypted data transmission provides greater protection against counterfeiting and unauthorized access, whereas barcodes are easily duplicated or tampered with. Integration of RFID with loss prevention systems significantly lowers shrinkage rates compared to traditional barcode methods, improving overall asset security.

Scalability for Large Retail Chains

RFID tagging offers superior scalability for large retail chains by enabling rapid, simultaneous scanning of thousands of items without line-of-sight requirements, significantly reducing inventory audit times compared to barcode scanning. Unlike barcode systems that require manual scanning of each item, RFID technology supports bulk scanning and seamless integration with automated inventory management systems, enhancing operational efficiency across multiple store locations. The ability of RFID to track real-time inventory data and reduce human error makes it a more scalable solution for expansive retail networks managing vast product assortments.

Future-Proofing: Adapting to Evolving Retail Needs

RFID tagging offers superior future-proofing over barcode scanning by enabling real-time inventory tracking, enhanced data accuracy, and seamless integration with IoT systems in retail environments. As retailers adopt omnichannel strategies and automated checkout solutions, RFID's ability to handle bulk scanning and provide detailed product insights becomes crucial. Investing in RFID technology aligns with evolving retail needs and supports scalability, improved customer experiences, and advanced supply chain management.

Choosing the Right Solution for Your Retail Business

RFID tagging offers faster inventory tracking and real-time data accuracy compared to barcode scanning, making it ideal for large retail operations with extensive stock. Barcode scanning remains a cost-effective solution for small to mid-sized retailers prioritizing ease of implementation and lower upfront investment. Evaluating factors like inventory size, budget, and required data granularity helps retailers select the most efficient technology for optimized supply chain management.

RFID Tagging vs Barcode Scanning Infographic

difterm.com

difterm.com