Monocoque construction integrates the vehicle's body and frame into a single, cohesive unit, enhancing structural rigidity and reducing overall weight for improved fuel efficiency and handling. Body-on-frame design consists of a separate chassis and body, providing superior durability and ease of repair, making it ideal for heavy-duty vehicles and off-road applications. Choosing between monocoque and body-on-frame depends on the balance between performance, comfort, and utility requirements in automotive design.

Table of Comparison

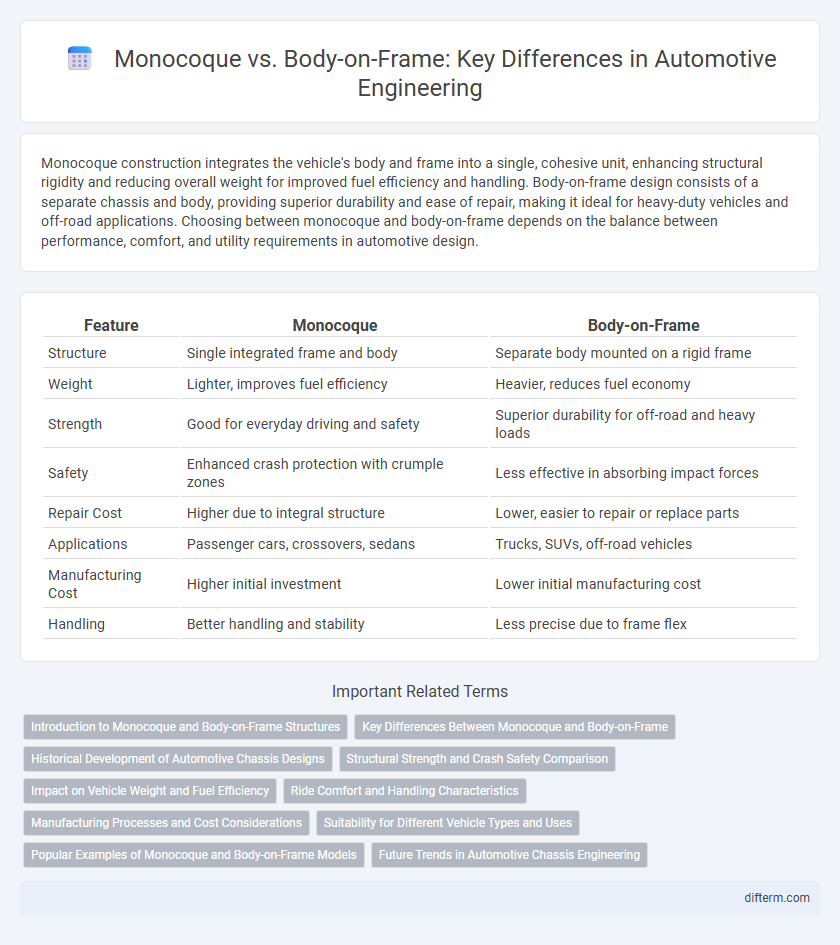

| Feature | Monocoque | Body-on-Frame |

|---|---|---|

| Structure | Single integrated frame and body | Separate body mounted on a rigid frame |

| Weight | Lighter, improves fuel efficiency | Heavier, reduces fuel economy |

| Strength | Good for everyday driving and safety | Superior durability for off-road and heavy loads |

| Safety | Enhanced crash protection with crumple zones | Less effective in absorbing impact forces |

| Repair Cost | Higher due to integral structure | Lower, easier to repair or replace parts |

| Applications | Passenger cars, crossovers, sedans | Trucks, SUVs, off-road vehicles |

| Manufacturing Cost | Higher initial investment | Lower initial manufacturing cost |

| Handling | Better handling and stability | Less precise due to frame flex |

Introduction to Monocoque and Body-on-Frame Structures

Monocoque and body-on-frame are two fundamental automotive chassis designs shaping vehicle performance and safety. Monocoque structures integrate the vehicle's body and frame into a single, lightweight shell, enhancing rigidity and crash protection through load distribution across the entire body. Body-on-frame construction, often used in trucks and SUVs, features a separate frame supporting the vehicle's mechanical components, offering durability and ease of repair for heavy-duty and off-road applications.

Key Differences Between Monocoque and Body-on-Frame

Monocoque construction integrates the vehicle's body and chassis into a single, cohesive structure, enhancing rigidity and reducing overall weight, which improves fuel efficiency and handling. Body-on-frame design involves a separate frame that supports the engine and drivetrain, offering superior durability and ease of repair, making it ideal for heavy-duty trucks and off-road vehicles. Monocoque vehicles typically provide better crash safety and refined driving dynamics, while body-on-frame vehicles excel in load-bearing capacity and off-road performance.

Historical Development of Automotive Chassis Designs

Early automotive chassis designs predominantly utilized body-on-frame construction, characterized by a separate rigid frame supporting the vehicle's mechanical components and body. The monocoque design emerged in the mid-20th century, integrating the body and frame into a single structural unit, enhancing rigidity and reducing weight for improved performance and fuel efficiency. This evolution marked a significant technological advancement, transitioning from heavy, truck-like chassis to lighter, safer, and more aerodynamic passenger vehicles.

Structural Strength and Crash Safety Comparison

Monocoque construction offers superior structural strength by integrating the body and chassis into a single cohesive unit, enhancing rigidity and reducing flex compared to body-on-frame designs. This increased stiffness improves crash safety by better absorbing and distributing impact forces, providing enhanced passenger protection during collisions. Body-on-frame vehicles, while traditionally favored for heavy-duty applications, typically exhibit lower structural integrity and higher susceptibility to deformation, which can compromise occupant safety in severe crashes.

Impact on Vehicle Weight and Fuel Efficiency

Monocoque construction significantly reduces vehicle weight by integrating the body and frame into a single unit, enhancing fuel efficiency through lower mass and improved aerodynamics. Body-on-frame designs typically add extra weight due to the separate chassis and body components, resulting in decreased fuel economy. Lightweight monocoque structures contribute to reduced emissions and better overall performance in automotive applications.

Ride Comfort and Handling Characteristics

Monocoque construction offers enhanced ride comfort by integrating the body and chassis, resulting in reduced vibrations and improved stiffness for better handling precision. Body-on-frame designs, while robust for off-road durability, often lead to a less refined ride due to increased flex and higher center of gravity. Advances in suspension tuning partially mitigate these issues, but monocoque vehicles generally provide superior handling responsiveness and smoother driving dynamics.

Manufacturing Processes and Cost Considerations

Monocoque construction integrates the vehicle's body and chassis into a single shell, streamlining manufacturing by reducing the number of parts and assembly steps, which lowers production costs. Body-on-frame design requires separate manufacturing of the frame and body, increasing complexity and labor costs but offering greater flexibility for customization and heavy-duty applications. The choice between these manufacturing processes impacts cost efficiency, with monocoque favored for mass-produced passenger cars due to its lighter weight and material savings.

Suitability for Different Vehicle Types and Uses

Monocoque construction offers superior rigidity and weight savings, making it ideal for passenger cars and compact SUVs focused on fuel efficiency and handling. Body-on-frame designs provide enhanced durability and ease of repair, preferred for heavy-duty trucks, off-road vehicles, and large SUVs requiring rugged performance and towing capacity. Vehicle manufacturers select monocoque or body-on-frame based on intended use, balancing factors like crash safety, load-bearing needs, and manufacturing costs.

Popular Examples of Monocoque and Body-on-Frame Models

Popular monocoque vehicles include the Honda Civic and the Tesla Model 3, known for their lightweight construction and improved fuel efficiency. Body-on-frame models like the Toyota Tacoma and Ford F-150 excel in durability and off-road capability due to their robust chassis design. The choice between monocoque and body-on-frame often depends on the intended use, with monocoque favored for passenger cars and body-on-frame preferred for trucks and SUVs.

Future Trends in Automotive Chassis Engineering

Future trends in automotive chassis engineering emphasize lightweight monocoque structures integrated with advanced composite materials to enhance fuel efficiency and crash safety. Body-on-frame designs remain relevant for heavy-duty and off-road vehicles, benefiting from modularity and ease of repair. Innovations in additive manufacturing and smart materials are expected to drive further evolution in chassis design, optimizing strength-to-weight ratios and sustainability.

monocoque vs body-on-frame Infographic

difterm.com

difterm.com