Intercooled turbos improve engine performance by cooling the compressed air, increasing its density and allowing more oxygen into the combustion chamber for better power output. Non-intercooled turbos send hot compressed air directly to the engine, which can reduce efficiency and increase the risk of engine knock due to higher intake temperatures. Choosing an intercooled turbo enhances overall vehicle efficiency, reduces exhaust gas temperatures, and supports longer engine life compared to non-intercooled setups.

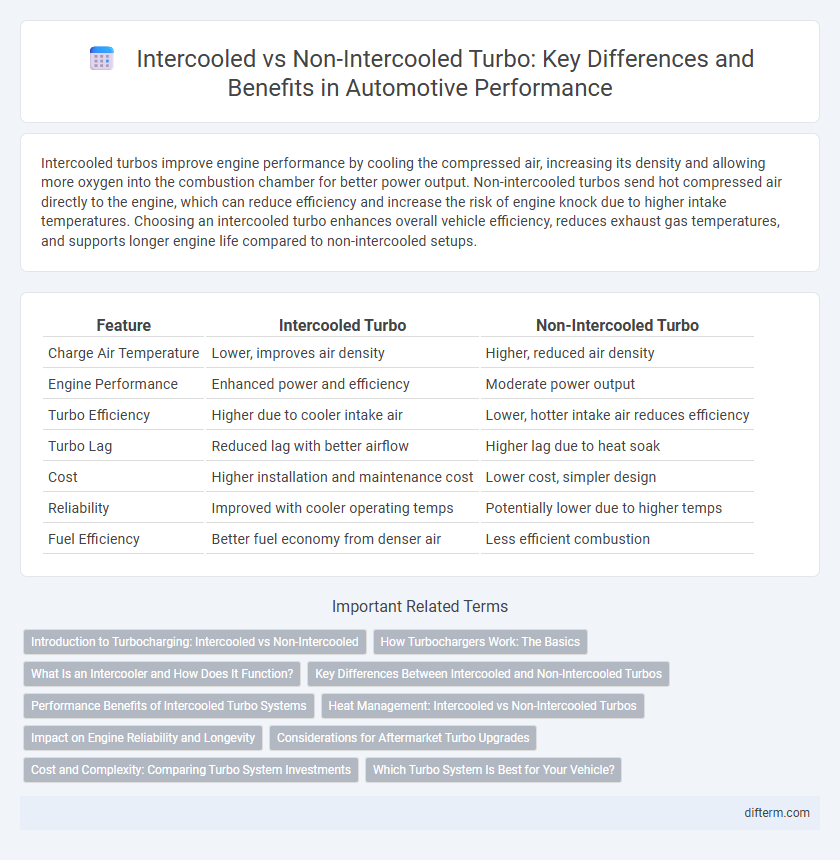

Table of Comparison

| Feature | Intercooled Turbo | Non-Intercooled Turbo |

|---|---|---|

| Charge Air Temperature | Lower, improves air density | Higher, reduced air density |

| Engine Performance | Enhanced power and efficiency | Moderate power output |

| Turbo Efficiency | Higher due to cooler intake air | Lower, hotter intake air reduces efficiency |

| Turbo Lag | Reduced lag with better airflow | Higher lag due to heat soak |

| Cost | Higher installation and maintenance cost | Lower cost, simpler design |

| Reliability | Improved with cooler operating temps | Potentially lower due to higher temps |

| Fuel Efficiency | Better fuel economy from denser air | Less efficient combustion |

Introduction to Turbocharging: Intercooled vs Non-Intercooled

Turbocharging enhances engine efficiency by forcing more air into the combustion chamber, with intercooled turbos specifically cooling compressed air to increase density and power output. Intercooled turbochargers reduce intake air temperatures, lowering the risk of engine knock and improving combustion stability, which leads to higher performance and better fuel efficiency. Non-intercooled turbos, while simpler and lighter, typically deliver warmer air that can limit power gains and increase thermal stress on the engine.

How Turbochargers Work: The Basics

Turbochargers increase engine power by using exhaust gases to spin a turbine connected to a compressor that forces more air into the combustion chamber. Intercooled turbos include an intercooler that cools compressed air before it enters the engine, improving air density and combustion efficiency, leading to better performance and reduced risk of engine knock. Non-intercooled turbos deliver hotter, less dense air, which can limit power gains and increase thermal stress on the engine components.

What Is an Intercooler and How Does It Function?

An intercooler is a heat exchanger designed to cool the compressed air from a turbocharger before it enters the engine, increasing air density and improving combustion efficiency. By reducing the temperature of the intake air, an intercooler enhances power output and reduces the risk of engine knocking. Unlike non-intercooled turbos that deliver hotter air, intercooled systems maintain cooler intake temperatures, resulting in better overall engine performance and longevity.

Key Differences Between Intercooled and Non-Intercooled Turbos

Intercooled turbos utilize an intercooler to reduce the temperature of compressed air, increasing air density and improving engine efficiency and power output. Non-intercooled turbos lack this cooling mechanism, resulting in higher intake air temperatures, which can lead to reduced performance and greater risk of engine knock. The key differences focus on thermal management, with intercooled turbos offering better reliability and optimized combustion under high boost conditions.

Performance Benefits of Intercooled Turbo Systems

Intercooled turbo systems significantly enhance engine performance by reducing the temperature of compressed air before it enters the combustion chamber, increasing air density and oxygen content for more efficient combustion. This results in higher power output, improved throttle response, and reduced risk of engine knock compared to non-intercooled turbos. Cooler intake air temperatures help maintain consistent performance under high boost conditions, enabling better reliability and fuel efficiency in automotive applications.

Heat Management: Intercooled vs Non-Intercooled Turbos

Intercooled turbos use an air-to-air or air-to-liquid heat exchanger to significantly reduce the temperature of compressed air, enhancing engine efficiency and preventing heat-related performance losses. Non-intercooled turbos deliver hotter intake air directly to the engine, which can increase thermal stress and reduce power output under sustained boost conditions. Effective heat management in intercooled systems minimizes the risk of detonation and improves overall engine reliability and longevity.

Impact on Engine Reliability and Longevity

Intercooled turbos reduce intake air temperatures, lowering thermal stress on engine components and enhancing durability compared to non-intercooled systems. Cooler, denser air improves combustion efficiency, minimizing the risk of knocking and prolonging engine lifespan. Non-intercooled turbos, operating with higher charge air temperatures, can accelerate wear on pistons, valves, and bearings, potentially compromising long-term reliability.

Considerations for Aftermarket Turbo Upgrades

Intercooled turbos significantly improve intake air density and reduce engine temperatures, enhancing performance and reliability in aftermarket turbo upgrades. Non-intercooled turbos may offer simpler installation and reduced cost but risk higher intake air temperatures, which can lead to detonation and reduced power output. Key considerations include desired power gains, thermal management, engine tuning adjustments, and compatibility with the vehicle's existing cooling system.

Cost and Complexity: Comparing Turbo System Investments

Intercooled turbo systems generally demand higher initial investments due to added components such as the intercooler, piping, and enhanced cooling requirements, increasing both material and labor costs. Non-intercooled turbos offer a simpler design with fewer parts, resulting in lower manufacturing expenses and easier maintenance. The cost-benefit analysis often hinges on performance gains from intercooled setups versus the reduced complexity and upfront savings of non-intercooled turbochargers.

Which Turbo System Is Best for Your Vehicle?

Intercooled turbo systems increase engine efficiency and power output by cooling compressed air before it enters the combustion chamber, reducing air temperature and increasing oxygen density. Non-intercooled turbos are simpler and lighter but may cause higher intake temperatures, leading to reduced performance and increased risk of engine knock. Choosing the best turbo system depends on your vehicle's application; intercooled turbos are ideal for high-performance or heavy-duty use, while non-intercooled setups suit lighter, budget-focused builds.

intercooled vs non-intercooled turbo Infographic

difterm.com

difterm.com