Ventilated rotors offer enhanced heat dissipation through internal vents, reducing brake fade during intense driving conditions. Cross-drilled rotors feature drilled holes that improve water and gas evacuation, boosting wet-weather braking performance. Choosing between the two depends on the driving style and specific performance needs, with ventilated rotors excelling in heat management and cross-drilled rotors providing better grip in wet environments.

Table of Comparison

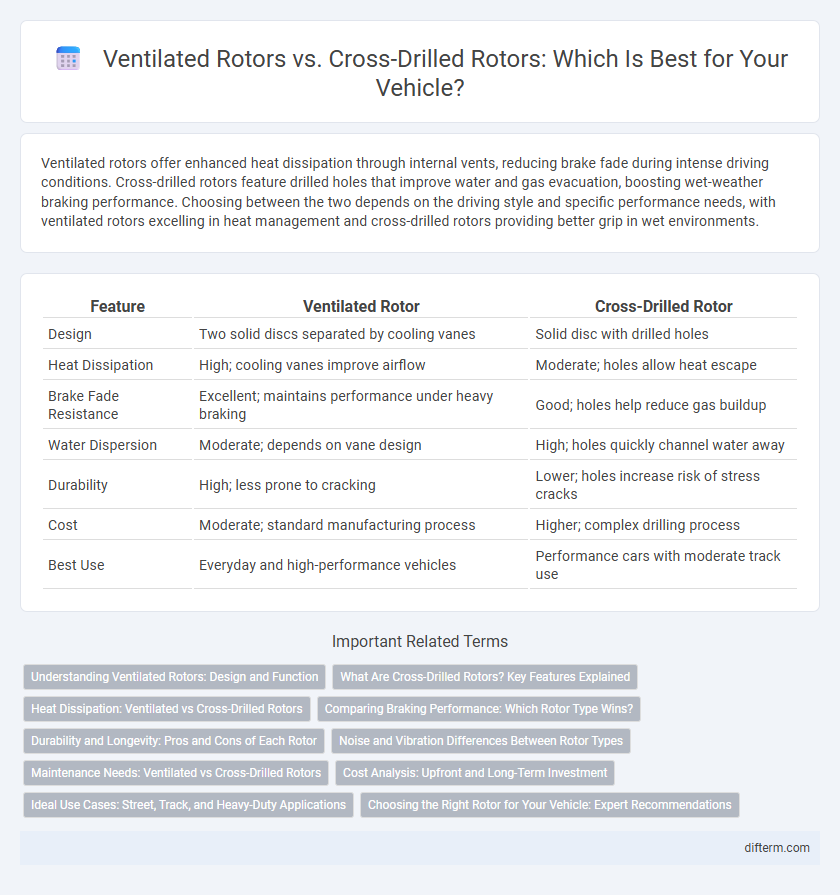

| Feature | Ventilated Rotor | Cross-Drilled Rotor |

|---|---|---|

| Design | Two solid discs separated by cooling vanes | Solid disc with drilled holes |

| Heat Dissipation | High; cooling vanes improve airflow | Moderate; holes allow heat escape |

| Brake Fade Resistance | Excellent; maintains performance under heavy braking | Good; holes help reduce gas buildup |

| Water Dispersion | Moderate; depends on vane design | High; holes quickly channel water away |

| Durability | High; less prone to cracking | Lower; holes increase risk of stress cracks |

| Cost | Moderate; standard manufacturing process | Higher; complex drilling process |

| Best Use | Everyday and high-performance vehicles | Performance cars with moderate track use |

Understanding Ventilated Rotors: Design and Function

Ventilated rotors feature internal vanes between two rotor surfaces, enhancing heat dissipation during braking and reducing the risk of brake fade under high-performance conditions. Their design promotes consistent cooling by allowing air to flow through the rotor, thereby improving braking efficiency and extending rotor lifespan. Compared to solid rotors, ventilated rotors offer superior thermal management crucial for both everyday driving and aggressive automotive use.

What Are Cross-Drilled Rotors? Key Features Explained

Cross-drilled rotors feature a series of precision-drilled holes that enhance heat dissipation and improve braking performance by reducing brake fade, especially under high-stress conditions. These holes also help expel gas, dust, and water from the brake surface, maintaining consistent friction between the pad and rotor. Commonly used in performance and sports vehicles, cross-drilled rotors prioritize cooling efficiency but may be more susceptible to cracking compared to ventilated rotors.

Heat Dissipation: Ventilated vs Cross-Drilled Rotors

Ventilated rotors feature internal vanes that enhance airflow, promoting superior heat dissipation during heavy braking compared to solid rotors. Cross-drilled rotors incorporate holes that allow gases and heat to escape more quickly, preventing brake fade but potentially increasing the risk of structural weakness under extreme stress. Overall, ventilated rotors provide more consistent thermal management for high-performance and heavy-duty automotive braking systems.

Comparing Braking Performance: Which Rotor Type Wins?

Ventilated rotors excel in heat dissipation due to their internal vanes, reducing brake fade during prolonged braking, while cross-drilled rotors offer enhanced initial bite and water dispersion for improved wet performance. In high-performance or track scenarios, ventilated rotors maintain consistent braking force under extreme temperatures, whereas cross-drilled rotors risk cracking from thermal stress despite better cooling surface area. Overall, for sustained braking performance and durability, ventilated rotors outperform cross-drilled rotors in most automotive applications.

Durability and Longevity: Pros and Cons of Each Rotor

Ventilated rotors enhance heat dissipation through their internal vanes, boosting durability by reducing the risk of warping and extending lifespan under heavy braking. Cross-drilled rotors provide improved cooling and performance in wet conditions but are prone to crack formation, which can limit longevity in aggressive driving scenarios. Choosing between ventilated and cross-drilled rotors depends on balancing the need for consistent durability against performance demands and maintenance frequency.

Noise and Vibration Differences Between Rotor Types

Ventilated rotors typically produce lower noise levels and reduced vibration due to their efficient heat dissipation through internal vanes, which maintains consistent braking performance. Cross-drilled rotors can generate higher noise and vibration because the holes may induce uneven surface wear and structural stress during braking. The design differences between ventilated and cross-drilled rotors significantly impact acoustic comfort and the smoothness of braking in automotive applications.

Maintenance Needs: Ventilated vs Cross-Drilled Rotors

Ventilated rotors require less frequent maintenance due to their design, which facilitates better heat dissipation and reduces the risk of warping. Cross-drilled rotors need more attention as the drilled holes can trap brake dust and moisture, leading to increased wear and potential cracking under high-stress conditions. Regular inspection and cleaning are essential for cross-drilled rotors to maintain optimal braking performance and longevity.

Cost Analysis: Upfront and Long-Term Investment

Ventilated rotors typically offer a lower upfront cost and increased durability, making them a cost-effective choice for standard automotive braking systems. Cross-drilled rotors, while more expensive initially due to complex manufacturing and advanced materials, provide enhanced heat dissipation and performance benefits that can reduce long-term maintenance expenses. Evaluating total ownership cost reveals ventilated rotors excel in budget-conscious applications, whereas cross-drilled rotors justify higher investment through improved brake efficiency and longevity in high-performance vehicles.

Ideal Use Cases: Street, Track, and Heavy-Duty Applications

Ventilated rotors excel in heavy-duty applications and street driving by providing consistent cooling and durability under prolonged braking. Cross-drilled rotors suit track enthusiasts seeking enhanced heat dissipation and improved wet-weather performance during aggressive driving conditions. Street vehicles benefit from ventilated rotors' noise reduction and longevity, while track cars leverage cross-drilled rotors for superior braking response and reduced fade.

Choosing the Right Rotor for Your Vehicle: Expert Recommendations

Ventilated rotors offer superior heat dissipation and are ideal for high-performance vehicles requiring enhanced braking stability under heavy load. Cross-drilled rotors improve water and gas evacuation, reducing brake fade during aggressive driving but may be prone to cracking under extreme stress. Experts recommend selecting ventilated rotors for daily driving and towing applications, while cross-drilled rotors suit sports cars needing aggressive braking response.

ventilated rotor vs cross-drilled rotor Infographic

difterm.com

difterm.com