Ladder frame chassis offer robust durability and off-road capability, making them ideal for heavy-duty automotive applications, while perimeter frames provide enhanced rigidity and better crash safety by distributing impact forces around the vehicle's outer edges. The ladder frame's straightforward design simplifies repairs and modifications, whereas the perimeter frame supports a more refined, car-like handling experience. Choosing between these frames depends on whether durability or handling and safety are prioritized in the vehicle's intended use.

Table of Comparison

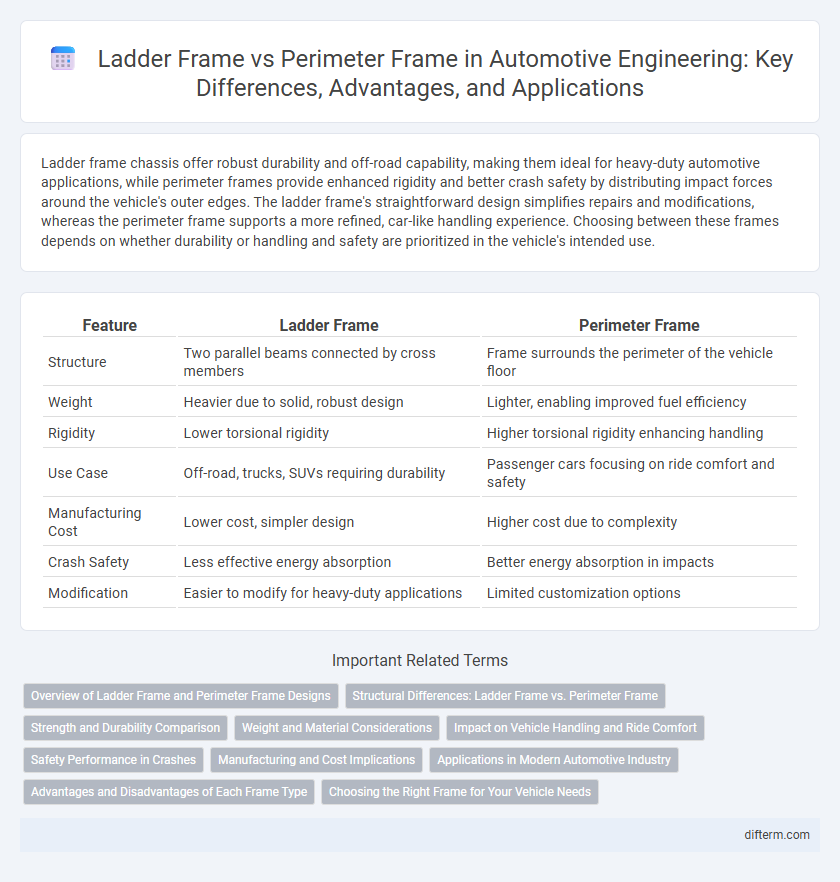

| Feature | Ladder Frame | Perimeter Frame |

|---|---|---|

| Structure | Two parallel beams connected by cross members | Frame surrounds the perimeter of the vehicle floor |

| Weight | Heavier due to solid, robust design | Lighter, enabling improved fuel efficiency |

| Rigidity | Lower torsional rigidity | Higher torsional rigidity enhancing handling |

| Use Case | Off-road, trucks, SUVs requiring durability | Passenger cars focusing on ride comfort and safety |

| Manufacturing Cost | Lower cost, simpler design | Higher cost due to complexity |

| Crash Safety | Less effective energy absorption | Better energy absorption in impacts |

| Modification | Easier to modify for heavy-duty applications | Limited customization options |

Overview of Ladder Frame and Perimeter Frame Designs

Ladder frame designs consist of two longitudinal beams connected by several cross members, offering high strength and durability ideal for heavy-duty and off-road vehicles. Perimeter frame designs, also known as box frames, feature a U-shaped channel that encircles the vehicle's perimeter, providing improved torsional rigidity and better crash protection. The ladder frame excels in load-bearing capacity and ease of repair, while the perimeter frame enhances vehicle stability and safety in passenger cars and light trucks.

Structural Differences: Ladder Frame vs. Perimeter Frame

Ladder frames consist of two longitudinal rails connected by several cross members, offering high rigidity and durability ideal for heavy-duty vehicles and off-road applications. Perimeter frames, designed with rails following the vehicle's outer edges, provide enhanced torsional stiffness and improved crash protection, commonly used in passenger cars and SUVs. The structural difference lies in the ladder frame's straightforward, robust architecture versus the perimeter frame's emphasis on rigidity and safety through the outer edge design.

Strength and Durability Comparison

Ladder frames, constructed with two longitudinal rails and cross members, excel in providing high structural strength and exceptional durability, especially in heavy-duty and off-road vehicles. Perimeter frames, designed to follow the vehicle's outer edges, offer improved rigidity and impact resistance, enhancing crashworthiness while maintaining sufficient strength for passenger cars. The ladder frame supports greater torsional loads and is less prone to fatigue over time, whereas perimeter frames optimize weight distribution and durability under normal driving conditions.

Weight and Material Considerations

Ladder frames, traditionally made from heavy steel, provide robust durability but result in higher vehicle weight, impacting fuel efficiency negatively. Perimeter frames often utilize lighter materials such as aluminum alloys, reducing overall weight while maintaining structural integrity and improving handling. The choice between these frame types hinges on balancing weight savings against strength, with perimeter frames favored in modern automotive design for enhanced efficiency.

Impact on Vehicle Handling and Ride Comfort

Ladder frames provide robust structural integrity, enhancing off-road durability but often resulting in a stiffer ride and less precise handling due to higher body roll. Perimeter frames improve vehicle handling by lowering the center of gravity and distributing weight more evenly, contributing to smoother ride comfort and better cornering stability. The perimeter frame's design reduces flex, allowing for improved suspension tuning and enhanced overall driving dynamics.

Safety Performance in Crashes

Ladder frames offer robust structural integrity with high resistance to torsional forces, making them beneficial in heavy-duty applications but generally underperforming in crash energy absorption compared to perimeter frames. Perimeter frames are designed to encircle the passenger compartment, providing enhanced rigidity and controlled deformation zones that improve occupant protection during collisions. Advanced perimeter frame designs integrate crumple zones effectively, delivering superior safety performance by dissipating impact energy and minimizing cabin intrusion in automotive crashes.

Manufacturing and Cost Implications

Ladder frames typically involve simpler manufacturing processes due to their straightforward design, leading to lower production costs and easier repairs. Perimeter frames require more complex engineering and materials, increasing manufacturing time and expenses but offering improved safety and rigidity. The choice between ladder and perimeter frames significantly impacts assembly line efficiency and overall vehicle cost structures.

Applications in Modern Automotive Industry

Ladder frames are primarily utilized in heavy-duty trucks and off-road vehicles due to their superior strength and ability to withstand high torsional forces, making them ideal for carrying heavy loads and rugged terrains. Perimeter frames dominate passenger cars and SUVs by providing enhanced crash safety and improved handling through a unified structure that optimizes weight distribution. The modern automotive industry increasingly favors perimeter frames for their compatibility with unibody construction and advanced safety features, while ladder frames remain essential for commercial and utility vehicle applications.

Advantages and Disadvantages of Each Frame Type

Ladder frames offer superior durability and load-bearing capacity, making them ideal for heavy-duty trucks and off-road vehicles, but they tend to be heavier and less flexible, impacting fuel efficiency and handling. Perimeter frames provide enhanced torsional rigidity and improved crash safety, contributing to better vehicle dynamics and occupant protection, though they may be less effective for extreme off-road conditions due to limited ground clearance. Choosing between ladder and perimeter frames depends on the automotive application's requirements for strength, weight, and ride quality.

Choosing the Right Frame for Your Vehicle Needs

Choosing the right vehicle frame depends on your driving requirements and terrain. Ladder frames offer superior strength and durability for heavy-duty use and off-road conditions, making them ideal for trucks and SUVs. Perimeter frames provide enhanced rigidity and better handling for passenger cars, improving safety and ride comfort on paved roads.

ladder frame vs perimeter frame Infographic

difterm.com

difterm.com