Belt-driven camshafts offer quieter operation and require less maintenance compared to chain-driven camshafts, which are known for their durability and longevity. Timing belts need regular replacement to prevent failure, while timing chains are more robust but can produce more noise and may stretch over time. Choosing between the two depends on factors like engine design, maintenance preferences, and desired performance characteristics.

Table of Comparison

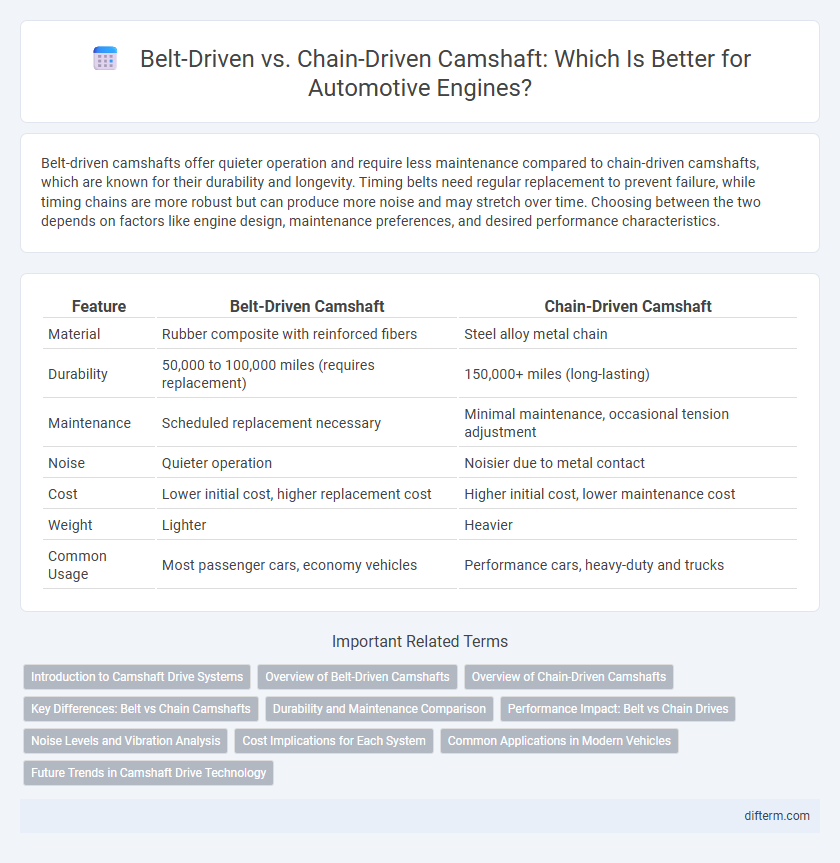

| Feature | Belt-Driven Camshaft | Chain-Driven Camshaft |

|---|---|---|

| Material | Rubber composite with reinforced fibers | Steel alloy metal chain |

| Durability | 50,000 to 100,000 miles (requires replacement) | 150,000+ miles (long-lasting) |

| Maintenance | Scheduled replacement necessary | Minimal maintenance, occasional tension adjustment |

| Noise | Quieter operation | Noisier due to metal contact |

| Cost | Lower initial cost, higher replacement cost | Higher initial cost, lower maintenance cost |

| Weight | Lighter | Heavier |

| Common Usage | Most passenger cars, economy vehicles | Performance cars, heavy-duty and trucks |

Introduction to Camshaft Drive Systems

Camshaft drive systems in automotive engines are primarily categorized into belt-driven and chain-driven types, each impacting engine performance and maintenance differently. Timing belts, typically made of high-strength rubber with fiberglass cords, provide quieter operation and require periodic replacement, often between 60,000 to 100,000 miles. In contrast, timing chains, constructed from metal links, offer greater durability and longevity with minimal maintenance, commonly lasting the vehicle's lifetime but may generate more noise compared to belts.

Overview of Belt-Driven Camshafts

Belt-driven camshafts utilize a timing belt made of high-strength rubber reinforced with fibers, offering quieter operation and reduced vibration compared to chain-driven systems. These belts require regular replacement, typically every 60,000 to 100,000 miles, to prevent failure that could lead to engine damage. The lightweight design of belt-driven camshafts contributes to improved fuel efficiency and smoother engine performance in many modern gasoline engines.

Overview of Chain-Driven Camshafts

Chain-driven camshafts utilize a metal chain to connect the camshaft to the crankshaft, offering enhanced durability and reduced maintenance compared to belt-driven systems. Commonly found in high-performance and heavy-duty engines, these systems provide precise timing, improved longevity, and resistance to wear and heat. The metal chain's robustness helps maintain engine timing accuracy over extended mileage, making it a preferred choice for vehicles requiring reliability under demanding conditions.

Key Differences: Belt vs Chain Camshafts

Belt-driven camshafts use a reinforced rubber timing belt that offers quiet operation and easier replacement but typically require maintenance every 60,000 to 100,000 miles. Chain-driven camshafts utilize a metal timing chain that provides greater durability and longevity, often lasting the vehicle's lifetime without replacement, albeit with a noisier operation. The choice between belt and chain camshafts impacts engine maintenance schedules, noise levels, and overall reliability in automotive performance.

Durability and Maintenance Comparison

Belt-driven camshafts typically require replacement every 60,000 to 100,000 miles due to wear and risk of snapping, making timely maintenance crucial to prevent engine damage. Chain-driven camshafts offer superior durability, often lasting the vehicle's lifetime with minimal maintenance, but may produce more noise and require occasional tensioner adjustments. Choosing between belt-driven and chain-driven systems impacts long-term maintenance costs and engine reliability in automotive applications.

Performance Impact: Belt vs Chain Drives

Belt-driven camshafts offer quieter operation and lighter weight, enhancing engine refinement and fuel efficiency, but typically require more frequent maintenance due to wear and potential slipping. Chain-driven camshafts provide superior durability and precise timing, supporting higher performance engines by maintaining consistent valve timing under extreme conditions. The choice between belt and chain directly influences engine reliability, maintenance intervals, and overall power delivery in automotive applications.

Noise Levels and Vibration Analysis

Belt-driven camshafts typically generate less noise and exhibit smoother operation due to the flexible rubber construction that dampens vibrations effectively. Chain-driven camshafts, while more durable, often produce higher noise levels and increased vibration due to metal-on-metal contact and less inherent damping. Advanced vibration analysis shows that belt drives reduce NVH (Noise, Vibration, and Harshness) impact, enhancing overall engine refinement in passenger vehicles.

Cost Implications for Each System

Belt-driven camshafts generally incur lower initial costs due to cheaper materials and simpler manufacturing processes, but they require more frequent replacement, increasing long-term maintenance expenses. Chain-driven camshafts have higher upfront costs because of durable metal components and complex engineering but offer greater longevity and reduced maintenance frequency, leading to lower lifetime costs. Evaluating total ownership expenses involves balancing the affordable initial investment of belt-driven systems against the durability and lower maintenance demands of chain-driven systems.

Common Applications in Modern Vehicles

Belt-driven camshafts are commonly found in passenger cars and light trucks due to their quieter operation and lower manufacturing costs, often used in vehicles prioritizing fuel efficiency and reduced noise. Chain-driven camshafts are prevalent in heavy-duty trucks, performance cars, and SUVs because of their durability and longer service intervals, making them ideal for engines exposed to high stress and extended mileage. Modern automotive manufacturers choose the camshaft drive system based on vehicle requirements, balancing maintenance frequency, engine noise, and longevity.

Future Trends in Camshaft Drive Technology

Future trends in camshaft drive technology emphasize the shift towards belt-driven systems due to their quieter operation, lower maintenance costs, and improved fuel efficiency compared to chain-driven counterparts. Innovations in high-performance synthetic materials and reinforced composites are enhancing belt durability and longevity, making them more competitive in high-stress engine environments. Meanwhile, chain-driven systems continue evolving with advanced metallurgy and reduced friction coatings to increase reliability and extend service intervals in heavy-duty and high-mileage vehicles.

Belt-driven vs Chain-driven camshaft Infographic

difterm.com

difterm.com