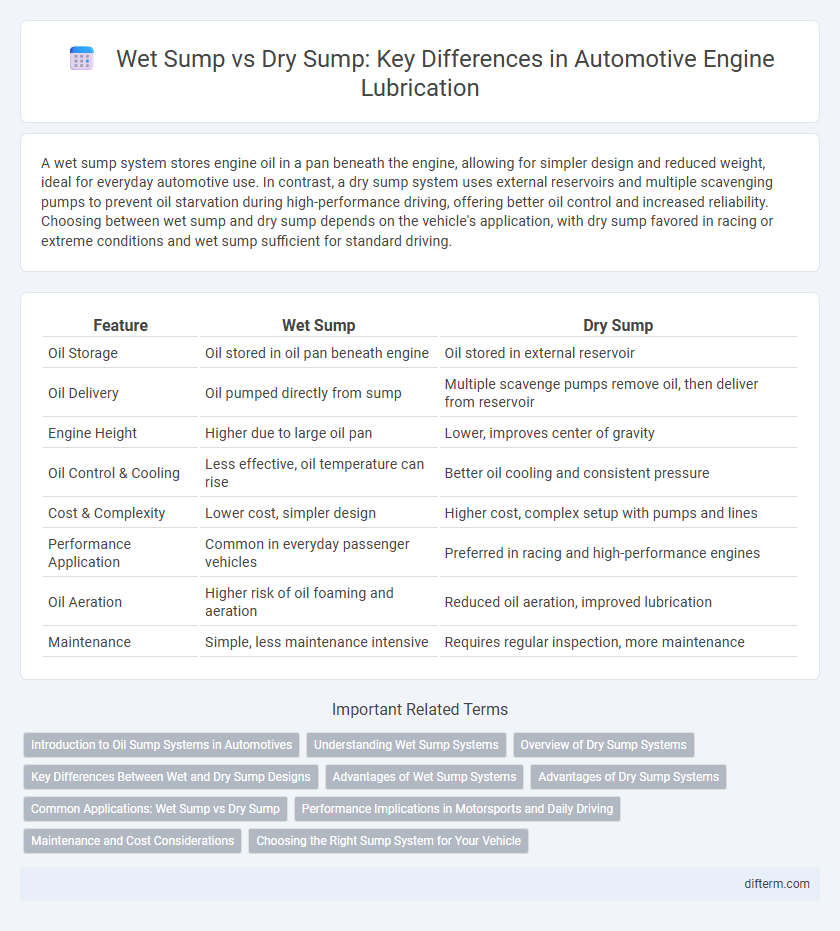

A wet sump system stores engine oil in a pan beneath the engine, allowing for simpler design and reduced weight, ideal for everyday automotive use. In contrast, a dry sump system uses external reservoirs and multiple scavenging pumps to prevent oil starvation during high-performance driving, offering better oil control and increased reliability. Choosing between wet sump and dry sump depends on the vehicle's application, with dry sump favored in racing or extreme conditions and wet sump sufficient for standard driving.

Table of Comparison

| Feature | Wet Sump | Dry Sump |

|---|---|---|

| Oil Storage | Oil stored in oil pan beneath engine | Oil stored in external reservoir |

| Oil Delivery | Oil pumped directly from sump | Multiple scavenge pumps remove oil, then deliver from reservoir |

| Engine Height | Higher due to large oil pan | Lower, improves center of gravity |

| Oil Control & Cooling | Less effective, oil temperature can rise | Better oil cooling and consistent pressure |

| Cost & Complexity | Lower cost, simpler design | Higher cost, complex setup with pumps and lines |

| Performance Application | Common in everyday passenger vehicles | Preferred in racing and high-performance engines |

| Oil Aeration | Higher risk of oil foaming and aeration | Reduced oil aeration, improved lubrication |

| Maintenance | Simple, less maintenance intensive | Requires regular inspection, more maintenance |

Introduction to Oil Sump Systems in Automotives

Oil sump systems in automotive engines play a crucial role in lubricating engine components by storing and supplying oil to reduce friction and wear. Wet sump systems house the oil in a pan beneath the engine, offering simplicity and cost-effectiveness, making them common in most passenger vehicles. Dry sump systems use an external reservoir and multiple scavenging pumps for improved oil control, enhanced cooling, and better performance in high-stress or racing applications.

Understanding Wet Sump Systems

Wet sump systems store engine oil in a pan beneath the crankshaft, allowing gravity to return oil after lubrication. This design reduces complexity and cost, making it common in everyday passenger vehicles and light-duty engines. Understanding the oil circulation in wet sump systems is essential for optimizing engine performance and maintaining proper lubrication under typical driving conditions.

Overview of Dry Sump Systems

Dry sump systems utilize external reservoirs and multiple scavenging pumps to maintain consistent oil pressure and prevent oil starvation during high-performance driving. These systems improve engine reliability by minimizing oil aeration and allowing better control of oil temperature and volume. Commonly used in racing and high-performance vehicles, dry sump systems enable lower engine placement, enhancing vehicle handling and center of gravity.

Key Differences Between Wet and Dry Sump Designs

Wet sump systems store engine oil in a pan beneath the crankshaft, ensuring simpler design and cost-efficiency, but can suffer from oil starvation during high-performance driving. Dry sump systems use external reservoirs and multiple scavenging pumps to maintain consistent oil pressure, enhancing engine reliability and lubrication under extreme conditions. The primary differences include oil storage location, complexity, cost, and performance benefits tailored to racing or high-output engines.

Advantages of Wet Sump Systems

Wet sump systems offer simpler design and lower manufacturing costs compared to dry sump setups, making them highly suitable for standard automotive engines. Their integrated oil reservoir reduces complexity and weight, enhancing overall vehicle efficiency. This system provides effective lubrication and cooling under normal driving conditions, supporting consistent engine performance.

Advantages of Dry Sump Systems

Dry sump systems offer superior oil control and lubrication under extreme driving conditions, preventing oil starvation during high-speed cornering and acceleration. These systems enhance engine reliability by maintaining consistent oil pressure and temperature, reducing wear and extending engine life. Furthermore, dry sump setups enable lower engine placement, improving vehicle center of gravity and handling performance.

Common Applications: Wet Sump vs Dry Sump

Wet sump oil systems are commonly used in passenger cars, motorcycles, and light trucks due to their simpler design, lower cost, and compact packaging that fits well within standard engine layouts. Dry sump systems are typically found in high-performance sports cars, racing vehicles, and heavy-duty trucks where enhanced oil control, reduced engine oil starvation, and improved reliability under extreme driving conditions are critical. Automotive applications requiring high G-force tolerance and consistent oil pressure favor dry sump systems for maintaining optimal engine lubrication and longevity.

Performance Implications in Motorsports and Daily Driving

Wet sump systems offer simpler design and lower cost, making them suitable for daily driving with steady oil pressure and sufficient cooling under normal conditions. Dry sump systems excel in motorsports by preventing oil starvation during high lateral G-forces and enabling consistent lubrication, enhancing engine reliability and performance. The improved oil control in dry sump setups also allows for lower engine placement, reducing the center of gravity and improving handling dynamics in racing applications.

Maintenance and Cost Considerations

Wet sump systems typically require less frequent maintenance and are more cost-effective due to simpler design and fewer components. Dry sump systems involve higher initial costs and more complex maintenance procedures, including oil reservoir checks and pump inspections. Choosing between the two depends on balancing lower ongoing maintenance expenses of wet sumps against the performance benefits and higher maintenance demands of dry sumps.

Choosing the Right Sump System for Your Vehicle

Selecting the right sump system depends on your vehicle's application, performance requirements, and engine design. Wet sump systems are ideal for standard road cars due to their simplicity, lower cost, and ease of maintenance, while dry sump systems excel in high-performance and racing vehicles by providing superior oil control, preventing oil starvation during aggressive cornering, and enabling lower engine placement for improved handling. Prioritizing factors such as engine configuration, usage conditions, and budget will help determine the most efficient and reliable sump solution for optimal engine lubrication and longevity.

wet sump vs dry sump Infographic

difterm.com

difterm.com