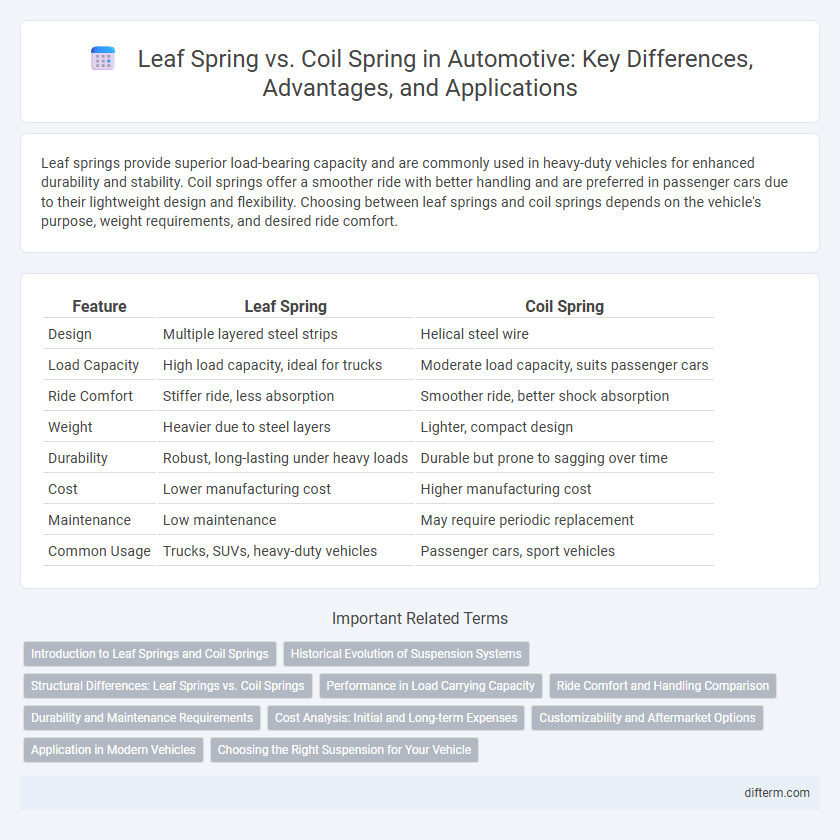

Leaf springs provide superior load-bearing capacity and are commonly used in heavy-duty vehicles for enhanced durability and stability. Coil springs offer a smoother ride with better handling and are preferred in passenger cars due to their lightweight design and flexibility. Choosing between leaf springs and coil springs depends on the vehicle's purpose, weight requirements, and desired ride comfort.

Table of Comparison

| Feature | Leaf Spring | Coil Spring |

|---|---|---|

| Design | Multiple layered steel strips | Helical steel wire |

| Load Capacity | High load capacity, ideal for trucks | Moderate load capacity, suits passenger cars |

| Ride Comfort | Stiffer ride, less absorption | Smoother ride, better shock absorption |

| Weight | Heavier due to steel layers | Lighter, compact design |

| Durability | Robust, long-lasting under heavy loads | Durable but prone to sagging over time |

| Cost | Lower manufacturing cost | Higher manufacturing cost |

| Maintenance | Low maintenance | May require periodic replacement |

| Common Usage | Trucks, SUVs, heavy-duty vehicles | Passenger cars, sport vehicles |

Introduction to Leaf Springs and Coil Springs

Leaf springs are traditional suspension components made of multiple layers of metal strips stacked together, primarily used in heavy-duty vehicles for load-bearing and durability. Coil springs consist of helical metal coils that provide greater flexibility and better ride comfort, commonly found in modern passenger cars. Both types serve critical roles in absorbing shocks and maintaining vehicle stability, with leaf springs excelling in heavy load support and coil springs offering enhanced suspension performance.

Historical Evolution of Suspension Systems

Leaf springs have been a fundamental suspension component since early automotive history, originating from horse-drawn carriages and gradually evolving with advancements in metallurgy and vehicle design. Coil springs emerged in the 20th century, offering improved ride comfort and weight savings compared to traditional leaf springs. The transition from leaf to coil springs marked a significant innovation in suspension systems, enhancing vehicle handling and durability.

Structural Differences: Leaf Springs vs. Coil Springs

Leaf springs consist of multiple layers of flat, flexible steel strips stacked and clamped together, providing both support and shock absorption through their arc-shaped structure. Coil springs are helical-shaped steel wires that compress and expand to absorb shocks, offering a more compact and flexible suspension design. Structurally, leaf springs distribute load across a wider area, making them suitable for heavy-duty vehicles, while coil springs deliver smoother ride quality in lighter automotive applications.

Performance in Load Carrying Capacity

Leaf springs provide superior load carrying capacity due to their multi-leaf design, enabling the distribution of weight over a larger surface area, making them ideal for heavy-duty trucks and commercial vehicles. Coil springs offer better ride comfort and flexibility but typically have lower load capacity compared to leaf springs, limiting their use in lighter or passenger vehicles. The choice between leaf springs and coil springs depends on the vehicle's intended load demands and performance requirements.

Ride Comfort and Handling Comparison

Leaf springs provide robust load-bearing capacity but tend to offer a stiffer ride, making them less ideal for ride comfort compared to coil springs. Coil springs deliver superior ride comfort by absorbing road irregularities more effectively and enhancing handling precision through better wheel control. Vehicles equipped with coil springs generally exhibit improved suspension responsiveness and smoother driving dynamics, especially in passenger cars and performance vehicles.

Durability and Maintenance Requirements

Leaf springs offer superior durability in heavy-duty applications due to their robust multi-leaf construction, which effectively distributes loads and resists wear under high-stress conditions. Coil springs require less frequent maintenance because of their simpler design and fewer components prone to corrosion or fatigue, making them ideal for lighter, everyday automotive use. Comparing both, leaf springs demand periodic inspections for sagging and cracking, while coil springs primarily need monitoring for signs of deformation or rust.

Cost Analysis: Initial and Long-term Expenses

Leaf springs generally offer lower initial costs due to simpler manufacturing and integration in heavy-duty vehicles, making them cost-effective for trucks and commercial vehicles. Coil springs incur higher upfront expenses but provide better ride comfort and durability, which can reduce long-term maintenance and replacement costs in passenger cars. Over time, the total cost of ownership favors coil springs in applications requiring frequent suspension performance and smoother handling, while leaf springs remain economical in load-bearing scenarios.

Customizability and Aftermarket Options

Leaf springs offer limited customizability due to their fixed design, making aftermarket upgrades less versatile compared to coil springs. Coil springs provide extensive customization opportunities through adjustable rates, progressive designs, and a wide variety of aftermarket brands, allowing tailored suspension setups. Enthusiasts and off-roaders prefer coil springs for their adaptability in tuning ride height and handling characteristics.

Application in Modern Vehicles

Leaf springs remain prevalent in heavy-duty trucks and commercial vehicles due to their superior load-bearing capacity and durability under high stress. Coil springs are favored in passenger cars and light-duty vehicles for their compact design, improved ride comfort, and enhanced handling characteristics. Modern automotive manufacturers often integrate coil springs with advanced suspension technologies such as MacPherson struts and multi-link systems for optimized performance in urban and off-road applications.

Choosing the Right Suspension for Your Vehicle

Leaf springs offer superior load-bearing capacity and durability, making them ideal for heavy-duty trucks and vehicles that frequently carry heavy loads. Coil springs provide better ride comfort and improved handling characteristics, preferred in passenger cars and light trucks for smoother driving experience. Selecting the right suspension depends on vehicle usage, load requirements, and desired ride quality to optimize performance and safety.

leaf spring vs coil spring Infographic

difterm.com

difterm.com