Viscosity index measures an oil's resistance to thinning at high temperatures, ensuring consistent lubrication, while pour point indicates the lowest temperature at which the oil remains fluid enough to flow. A higher viscosity index oil maintains stable performance across a broad temperature range, whereas a lower pour point oil allows better cold-start protection in automotive engines. Understanding the balance between viscosity index and pour point is essential for selecting automotive oils that optimize engine efficiency and longevity in varying climate conditions.

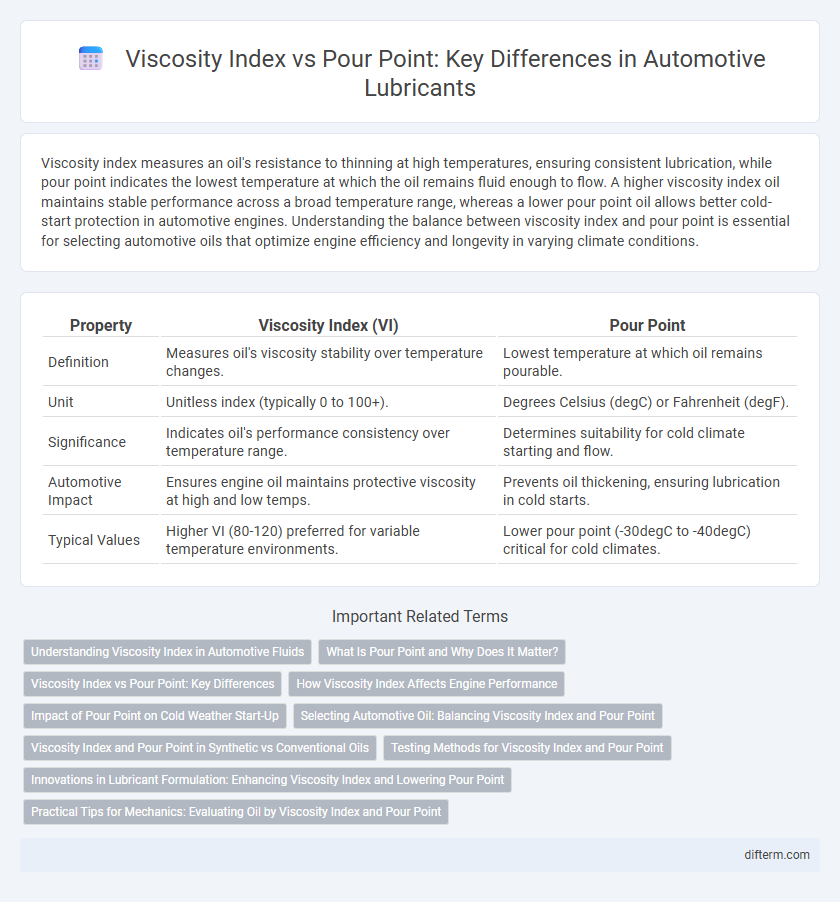

Table of Comparison

| Property | Viscosity Index (VI) | Pour Point |

|---|---|---|

| Definition | Measures oil's viscosity stability over temperature changes. | Lowest temperature at which oil remains pourable. |

| Unit | Unitless index (typically 0 to 100+). | Degrees Celsius (degC) or Fahrenheit (degF). |

| Significance | Indicates oil's performance consistency over temperature range. | Determines suitability for cold climate starting and flow. |

| Automotive Impact | Ensures engine oil maintains protective viscosity at high and low temps. | Prevents oil thickening, ensuring lubrication in cold starts. |

| Typical Values | Higher VI (80-120) preferred for variable temperature environments. | Lower pour point (-30degC to -40degC) critical for cold climates. |

Understanding Viscosity Index in Automotive Fluids

Viscosity index (VI) measures an automotive fluid's resistance to viscosity changes with temperature fluctuations, ensuring consistent lubrication performance in engines and transmissions. A higher VI indicates better stability, allowing the fluid to maintain optimal thickness in both cold starts and high operating temperatures. In contrast, pour point defines the lowest temperature at which the fluid remains pourable but does not directly reflect its viscosity behavior across the temperature range.

What Is Pour Point and Why Does It Matter?

Pour point is the lowest temperature at which an automotive lubricant remains fluid and can still be poured, indicating its ability to function in cold environments. This property is critical because it determines how well engine oil maintains flow and protects engine components during cold starts. Understanding pour point helps in selecting oils that prevent viscosity increase and ensure optimal lubrication in low-temperature conditions.

Viscosity Index vs Pour Point: Key Differences

Viscosity Index measures an oil's change in viscosity with temperature, indicating its stability under varying thermal conditions, while Pour Point defines the lowest temperature at which the oil remains fluid and can still flow. High Viscosity Index oils maintain consistent lubrication performance across temperature fluctuations, critical for automotive engines exposed to diverse climates. Pour Point is crucial for cold-start conditions, ensuring engine components receive proper lubrication and preventing wear during low-temperature operation.

How Viscosity Index Affects Engine Performance

Viscosity index (VI) measures an oil's resistance to viscosity changes with temperature, which directly influences engine lubrication efficiency and wear protection. A higher VI ensures stable viscosity across various operating temperatures, maintaining optimal oil film strength and reducing friction in engine components. This prevents excessive wear and improves fuel efficiency, while the pour point determines the lowest temperature at which the oil remains fluid, critical for cold-start performance but less indicative of overall engine protection than VI.

Impact of Pour Point on Cold Weather Start-Up

Pour point significantly influences cold weather start-up by indicating the lowest temperature at which an engine oil remains fluid enough to pump effectively, preventing sluggish lubrication during engine ignition. A low pour point ensures that oil flows rapidly in subzero temperatures, reducing wear and improving engine protection during initial startup. While viscosity index measures oil thickness stability across temperatures, pour point specifically dictates performance in extreme cold conditions critical for reliable automotive operation.

Selecting Automotive Oil: Balancing Viscosity Index and Pour Point

Selecting automotive oil requires balancing viscosity index, which indicates the oil's ability to maintain consistent viscosity across temperature variations, against pour point, the lowest temperature at which the oil flows. A high viscosity index ensures optimal engine protection in both hot and cold conditions, while a low pour point guarantees ease of cold starts and effective lubrication in freezing environments. Prioritizing oils with a balanced viscosity index and low pour point enhances engine performance, fuel efficiency, and long-term durability.

Viscosity Index and Pour Point in Synthetic vs Conventional Oils

Viscosity Index (VI) measures an oil's resistance to viscosity changes with temperature, typically higher in synthetic oils due to their uniform molecular structure, ensuring consistent lubrication under extreme conditions. Pour Point indicates the lowest temperature at which the oil remains fluid, with synthetic oils generally exhibiting lower pour points than conventional oils, allowing better performance in cold environments. Synthetic oils thus provide superior temperature stability and flow characteristics compared to conventional oils, enhancing engine protection and efficiency.

Testing Methods for Viscosity Index and Pour Point

Viscosity index testing involves measuring the oil's viscosity at two standard temperatures, typically 40degC and 100degC, using a viscometer to assess its change with temperature. Pour point is determined through ASTM D97 or the more sensitive ASTM D5950 method, where the oil sample is cooled gradually until it ceases to flow, indicating the lowest temperature at which the lubricant remains fluid. These standardized testing methods ensure accurate evaluation of oil performance under varying temperature conditions critical for automotive lubricant selection.

Innovations in Lubricant Formulation: Enhancing Viscosity Index and Lowering Pour Point

Innovations in lubricant formulation have led to advanced additive technologies that significantly enhance the viscosity index, ensuring stable viscosity across a wide temperature range in automotive applications. By incorporating synthetic base oils and multifunctional additives, manufacturers achieve lower pour points, improving cold start performance and reducing engine wear during harsh winter conditions. These advancements optimize engine efficiency and longevity, addressing the critical balance between viscosity stability and low-temperature fluidity.

Practical Tips for Mechanics: Evaluating Oil by Viscosity Index and Pour Point

Mechanics should prioritize oils with a high viscosity index to ensure stable viscosity across temperature variations, preventing engine wear during operation. Evaluating the pour point is crucial for cold climates, as oils with lower pour points maintain fluidity and protect engine components during startup in freezing conditions. Selecting lubricants based on these properties helps optimize engine performance and longevity under diverse environmental stresses.

viscosity index vs pour point Infographic

difterm.com

difterm.com