Torsen differentials provide superior torque distribution by using gears to instantly transfer power to the wheel with the most traction, enhancing performance in demanding driving conditions. Viscous differentials rely on a fluid coupling mechanism that gradually transfers torque between wheels, offering smoother operation but slower response to traction changes. For automotive applications, Torsen differentials are preferred for their durability and precise handling, while viscous differentials suit everyday driving with less aggressive traction needs.

Table of Comparison

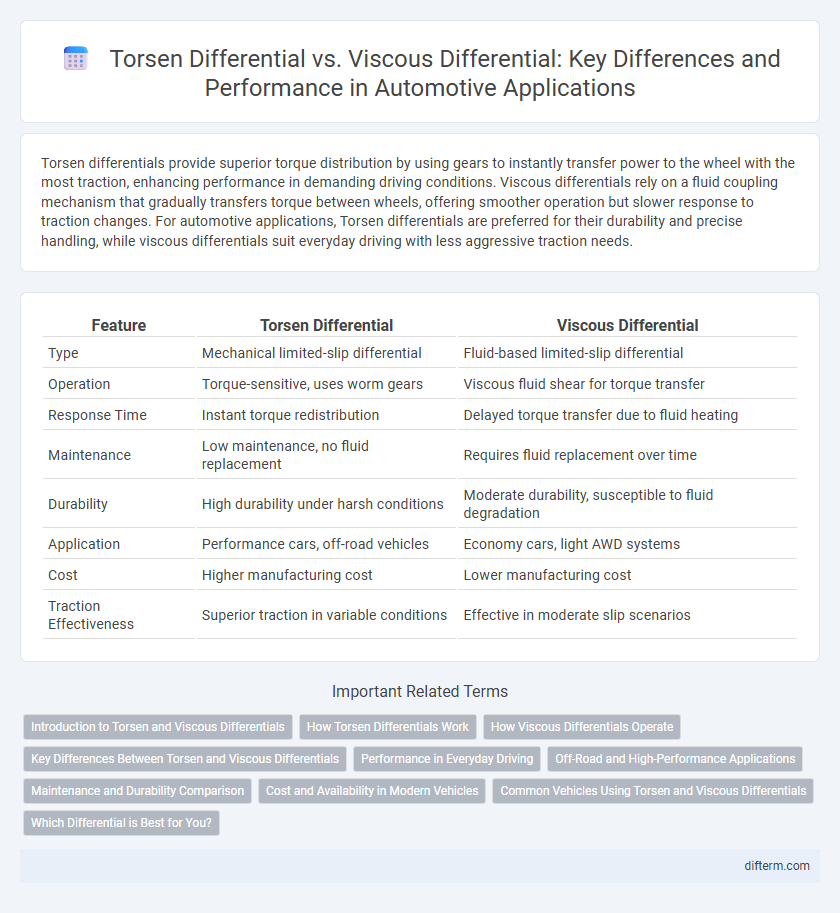

| Feature | Torsen Differential | Viscous Differential |

|---|---|---|

| Type | Mechanical limited-slip differential | Fluid-based limited-slip differential |

| Operation | Torque-sensitive, uses worm gears | Viscous fluid shear for torque transfer |

| Response Time | Instant torque redistribution | Delayed torque transfer due to fluid heating |

| Maintenance | Low maintenance, no fluid replacement | Requires fluid replacement over time |

| Durability | High durability under harsh conditions | Moderate durability, susceptible to fluid degradation |

| Application | Performance cars, off-road vehicles | Economy cars, light AWD systems |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

| Traction Effectiveness | Superior traction in variable conditions | Effective in moderate slip scenarios |

Introduction to Torsen and Viscous Differentials

Torsen differentials use a set of helical gears to distribute torque between wheels, providing precise and continuous traction control in varying driving conditions. Viscous differentials rely on a silicone-based fluid that transfers torque by resistance, offering smooth engagement primarily during wheel slip. Both systems enhance vehicle stability and cornering performance but differ significantly in response time and mechanical complexity.

How Torsen Differentials Work

Torsen differentials operate using a series of helical gears that automatically distribute torque between wheels based on traction, providing precise torque vectoring without requiring electronic control. Unlike viscous differentials that rely on fluid viscosity to limit slip, Torsen systems offer immediate mechanical response, improving handling and stability in varying driving conditions. Their ability to transfer torque efficiently to the wheel with better grip enhances cornering performance and reduces wheel spin on slippery surfaces.

How Viscous Differentials Operate

Viscous differentials operate by using a silicone-based fluid contained within a sealed chamber to transfer torque between wheels. When a difference in wheel speed occurs, the fluid's viscosity causes resistance, gradually distributing torque to the slower wheel to enhance traction. This system provides smooth torque transfer and improved stability, especially in low-traction conditions commonly encountered in automotive applications.

Key Differences Between Torsen and Viscous Differentials

Torsen differentials use a gear-based system to provide instant, torque-sensing power distribution between wheels, enhancing traction and handling in performance vehicles. Viscous differentials rely on a silicone-based fluid that shears under slip conditions, gradually transferring torque to the wheel with more grip, often resulting in a slower response. The Torsen's mechanical complexity offers precise control and durability, while the viscous design provides cost-effectiveness and smoother engagement in everyday driving conditions.

Performance in Everyday Driving

Torsen differentials offer superior torque distribution and faster response times, enhancing traction and handling during everyday driving conditions. Viscous differentials provide smoother, gradual torque transfer ideal for typical road surfaces but may lag under sudden traction loss. Overall, Torsen differentials deliver more precise performance for dynamic everyday driving, while viscous types favor consistent, low-maintenance operation.

Off-Road and High-Performance Applications

Torsen differentials provide superior torque distribution and enhanced traction in off-road and high-performance vehicles due to their mechanical design, which instantly reacts to wheel slip without delay. Viscous differentials use a silicone-based fluid to transfer torque, offering smoother operation but slower response times, making them less ideal for aggressive off-road conditions and high-speed performance driving. The Torsen differential's ability to deliver precise, real-time torque vectoring significantly improves vehicle stability and cornering performance under extreme driving scenarios.

Maintenance and Durability Comparison

Torsen differentials offer superior durability due to their all-metal gears, requiring minimal maintenance and excelling in high-torque applications. Viscous differentials depend on silicone-based fluids that degrade over time, necessitating periodic fluid replacement to maintain performance and avoid failures. The robust mechanical design of Torsen units ensures longer service life under harsh driving conditions compared to the wear-prone viscous couplings.

Cost and Availability in Modern Vehicles

Torsen differentials generally have higher manufacturing costs due to their complex gear design, resulting in limited availability primarily in performance and luxury vehicles. Viscous differentials offer a more cost-effective solution with widespread use in mainstream cars, benefiting from simpler construction and easier integration. The balance between cost and availability makes viscous differentials the preferred choice for most modern vehicles aiming for affordability and reliability.

Common Vehicles Using Torsen and Viscous Differentials

Common vehicles using Torsen differentials include models like the Audi Quattro series and certain Subaru WRX variants, prized for their torque-sensing capabilities that enhance traction and performance on varying road conditions. Popular cars equipped with viscous differentials are older Jeep Cherokee models and some Nissan 4x4 trucks, which rely on the fluid-based system to distribute torque when wheel slippage is detected. The choice between Torsen and viscous differentials often reflects the manufacturer's focus on either dynamic driving response or cost-effective traction control in all-wheel-drive systems.

Which Differential is Best for You?

Torsen differentials provide superior torque distribution and faster response times, making them ideal for performance vehicles and off-road driving. Viscous differentials offer smoother operation and cost-effective traction control, suitable for regular commuting and mild off-road use. Choosing between Torsen and viscous differentials depends on driving style, budget, and the level of traction performance required.

Torsen differential vs Viscous differential Infographic

difterm.com

difterm.com