Throttle by wire systems offer improved fuel efficiency and faster response times compared to traditional cable throttle setups, enhancing overall vehicle performance. Electronic control enables precise throttle adjustments, reducing mechanical wear and simplifying engine management integration. Cable throttles, while reliable and straightforward, often lack the adaptability and diagnostic capabilities provided by modern drive-by-wire technology.

Table of Comparison

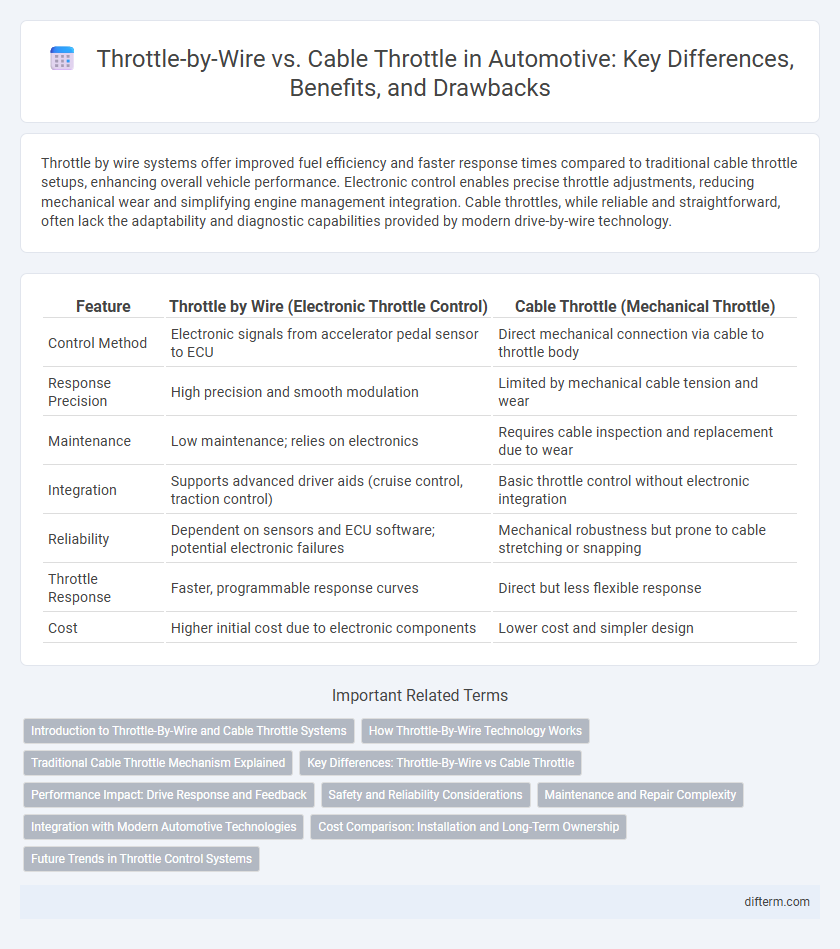

| Feature | Throttle by Wire (Electronic Throttle Control) | Cable Throttle (Mechanical Throttle) |

|---|---|---|

| Control Method | Electronic signals from accelerator pedal sensor to ECU | Direct mechanical connection via cable to throttle body |

| Response Precision | High precision and smooth modulation | Limited by mechanical cable tension and wear |

| Maintenance | Low maintenance; relies on electronics | Requires cable inspection and replacement due to wear |

| Integration | Supports advanced driver aids (cruise control, traction control) | Basic throttle control without electronic integration |

| Reliability | Dependent on sensors and ECU software; potential electronic failures | Mechanical robustness but prone to cable stretching or snapping |

| Throttle Response | Faster, programmable response curves | Direct but less flexible response |

| Cost | Higher initial cost due to electronic components | Lower cost and simpler design |

Introduction to Throttle-By-Wire and Cable Throttle Systems

Throttle-by-wire systems replace traditional mechanical cable linkages with electronic sensors and actuators to control engine throttle, enhancing precision and response time. Cable throttle systems rely on a physical cable connecting the accelerator pedal to the throttle body, offering simplicity but limited adaptability. Modern vehicles increasingly adopt throttle-by-wire technology for improved fuel efficiency, emissions control, and integration with advanced driver-assistance systems (ADAS).

How Throttle-By-Wire Technology Works

Throttle-by-wire technology uses electronic sensors to detect the accelerator pedal position, sending digital signals to the engine control unit (ECU) to regulate the throttle valve. This system replaces traditional mechanical cables with precise electronic control, enabling improved fuel efficiency, reduced emissions, and enhanced vehicle responsiveness. By continuously monitoring vehicle parameters, throttle-by-wire optimizes engine performance and supports advanced driver-assistance features such as traction control and adaptive cruise control.

Traditional Cable Throttle Mechanism Explained

The traditional cable throttle mechanism in automotive systems uses a direct mechanical linkage between the accelerator pedal and the throttle valve, relying on a steel cable to transmit driver input. This system provides immediate and tactile feedback, ensuring precise throttle control without electronic intervention. Despite its simplicity and reliability, it lacks the adaptability and integration capabilities offered by modern throttle-by-wire systems.

Key Differences: Throttle-By-Wire vs Cable Throttle

Throttle-by-wire systems replace the traditional mechanical cable with electronic sensors and actuators, enabling more precise control of engine throttle response and improved fuel efficiency. Unlike cable throttle systems that directly link the accelerator pedal to the throttle valve, throttle-by-wire utilizes input from the pedal sensor to electronically regulate throttle position, enhancing integration with vehicle stability and traction control systems. This electronic approach reduces mechanical wear and allows customizable throttle mapping for optimized performance and emissions control.

Performance Impact: Drive Response and Feedback

Throttle-by-wire systems enhance drive response by providing precise electronic control of the throttle valve, resulting in smoother acceleration and improved fuel efficiency compared to traditional cable throttle mechanisms. This technology allows for customizable throttle mapping that adapts to driving conditions, enhancing performance and reducing lag often experienced with mechanical linkages. Feedback from throttle-by-wire setups also integrates seamlessly with traction control and stability systems, optimizing overall vehicle dynamics and driver experience.

Safety and Reliability Considerations

Throttle by wire systems enhance safety through precise electronic control and integrated fail-safe mechanisms, reducing mechanical wear and potential cable failure risks. Cable throttle systems rely on direct physical connections prone to wear, stretching, or snapping, which can compromise reliability and response consistency. Advanced diagnostics in throttle by wire enable real-time monitoring and intervention, improving overall vehicle safety and operational reliability.

Maintenance and Repair Complexity

Throttle-by-wire systems require specialized diagnostic tools and software updates for maintenance, increasing repair complexity compared to traditional cable throttle systems. Cable throttles feature simpler mechanical linkages that are easier to inspect and repair without advanced equipment, reducing downtime and labor costs. Repairing throttle-by-wire components often demands manufacturer-specific knowledge, making maintenance less accessible for independent garages.

Integration with Modern Automotive Technologies

Throttle by wire systems enable seamless integration with advanced driver-assistance systems (ADAS), adaptive cruise control, and electronic stability control by precisely controlling engine response through electronic signals. Cable throttle mechanisms lack this level of integration, relying on mechanical linkages that limit responsiveness and compatibility with modern vehicle electronic architectures. The electronic control in throttle by wire also facilitates real-time engine management, improving fuel efficiency, emissions, and vehicle performance in connected automotive ecosystems.

Cost Comparison: Installation and Long-Term Ownership

Throttle by wire systems generally have higher initial installation costs due to advanced sensors and electronic controls but offer lower maintenance expenses over time compared to traditional cable throttles, which incur frequent mechanical adjustments and replacements. Cable throttle systems are cheaper upfront but tend to increase ownership costs with wear and cable stretching requiring regular servicing. The long-term cost-effectiveness of throttle by wire technology stems from improved precision, reduced mechanical failures, and integration with modern engine management systems.

Future Trends in Throttle Control Systems

Throttle by wire systems are set to dominate future automotive trends due to their precise electronic control and integration with advanced driver-assistance systems (ADAS). These systems enable improved fuel efficiency, reduced emissions, and enhanced performance through real-time data processing and adaptive throttle response. Continued advancements in sensor technology, artificial intelligence, and cybersecurity will further promote the shift from traditional cable throttle mechanisms to fully electronic throttle control systems.

throttle by wire vs cable throttle Infographic

difterm.com

difterm.com