Ventilated disc brakes provide superior heat dissipation compared to solid disc brakes, reducing the risk of brake fade during intense or prolonged use. This design features internal vanes that allow air to flow through the disc, enhancing cooling efficiency and improving overall braking performance. Solid discs, while simpler and typically more cost-effective, tend to retain more heat, making them less suitable for high-performance or heavy-duty automotive applications.

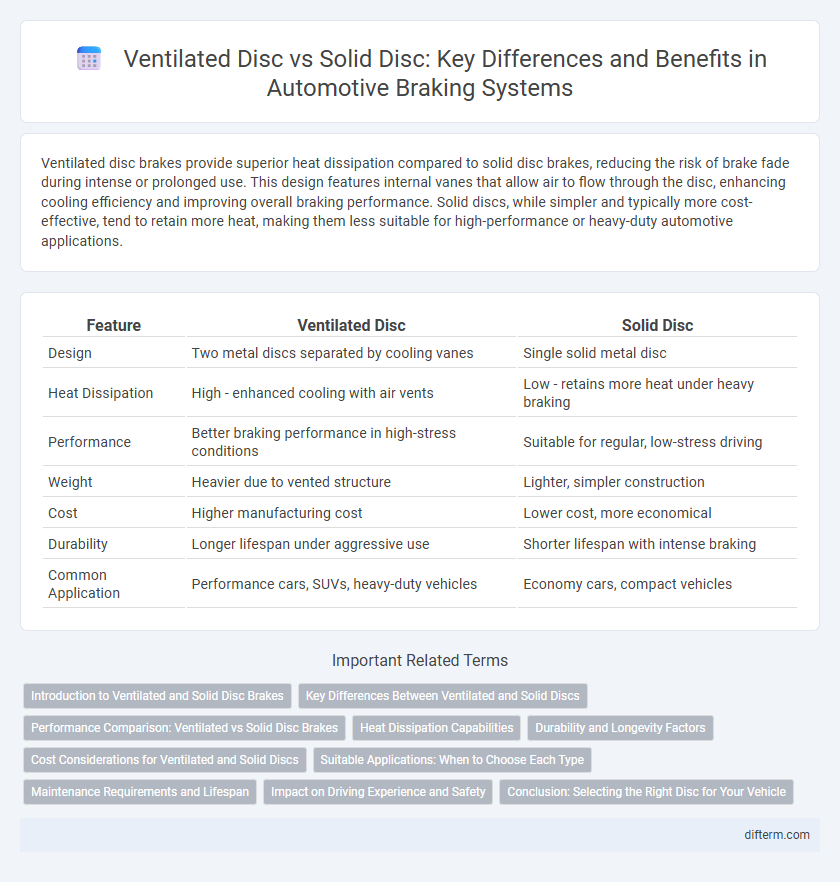

Table of Comparison

| Feature | Ventilated Disc | Solid Disc |

|---|---|---|

| Design | Two metal discs separated by cooling vanes | Single solid metal disc |

| Heat Dissipation | High - enhanced cooling with air vents | Low - retains more heat under heavy braking |

| Performance | Better braking performance in high-stress conditions | Suitable for regular, low-stress driving |

| Weight | Heavier due to vented structure | Lighter, simpler construction |

| Cost | Higher manufacturing cost | Lower cost, more economical |

| Durability | Longer lifespan under aggressive use | Shorter lifespan with intense braking |

| Common Application | Performance cars, SUVs, heavy-duty vehicles | Economy cars, compact vehicles |

Introduction to Ventilated and Solid Disc Brakes

Ventilated disc brakes feature a dual-disc design with internal vanes allowing air to flow between the discs, significantly improving heat dissipation compared to solid disc brakes. Solid disc brakes consist of a single, solid piece of metal, which offers simplicity and lower cost but tends to retain more heat under heavy braking conditions. The enhanced cooling capability of ventilated discs reduces brake fade, making them preferable for high-performance and heavy-duty automotive applications.

Key Differences Between Ventilated and Solid Discs

Ventilated discs feature internal channels that enhance heat dissipation, reducing brake fade during heavy braking, whereas solid discs have a uniform, non-perforated design that offers simplicity and lower cost. The increased surface area and airflow in ventilated discs improve cooling performance, making them ideal for high-performance and heavy-duty vehicles, while solid discs are commonly used in standard, low-load applications. Material composition and thickness also differ, with ventilated discs often being thicker and made from high-grade alloys to withstand greater thermal stress.

Performance Comparison: Ventilated vs Solid Disc Brakes

Ventilated disc brakes offer superior heat dissipation compared to solid disc brakes, which significantly reduces the risk of brake fade during heavy or prolonged braking, enhancing overall safety and performance. Solid disc brakes tend to retain more heat, which can lead to quicker wear and reduced braking efficiency under high-stress conditions. In high-performance and heavy-duty vehicles, ventilated discs provide more consistent stopping power and greater durability, making them the preferred choice for demanding driving scenarios.

Heat Dissipation Capabilities

Ventilated discs exhibit superior heat dissipation capabilities compared to solid discs due to their internal cooling channels that allow air to circulate and reduce brake fade under heavy braking conditions. Solid discs lack this airflow mechanism, causing heat to accumulate rapidly and potentially compromising braking performance. Effective thermal management in ventilated discs translates to enhanced durability and consistent braking efficiency in high-performance and heavy-duty automotive applications.

Durability and Longevity Factors

Ventilated discs feature internal vanes that enhance heat dissipation, significantly reducing the risk of brake fade and extending overall durability compared to solid discs. Solid discs, while simpler and often more cost-effective, tend to retain heat longer, which can cause faster wear and decreased longevity under high-stress driving conditions. The improved airflow and cooling efficiency of ventilated discs directly contribute to a longer lifespan and more consistent braking performance in automotive applications.

Cost Considerations for Ventilated and Solid Discs

Ventilated disc brakes generally incur higher manufacturing and replacement costs due to their complex design incorporating internal cooling channels, which enhance heat dissipation and performance during high-demand braking scenarios. Solid discs, being simpler and more compact, present a more cost-effective option with lower initial purchase and maintenance expenses, making them ideal for standard driving conditions. However, the long-term cost benefits of ventilated discs emerge in applications requiring frequent heavy braking, as they reduce the risk of brake fade and extend component lifespan.

Suitable Applications: When to Choose Each Type

Ventilated disc brakes are ideal for high-performance vehicles and heavy-duty applications because they offer superior heat dissipation and reduce brake fade under intense use. Solid disc brakes are best suited for lighter vehicles and everyday driving where braking demands are moderate, providing sufficient stopping power at a lower cost. Choosing ventilated discs enhances safety and performance in aggressive driving conditions, while solid discs deliver reliable braking for standard commuting and light loads.

Maintenance Requirements and Lifespan

Ventilated disc brakes, featuring internal cooling channels, offer superior heat dissipation, reducing the risk of brake fade and extending pad and rotor lifespan compared to solid discs. Maintenance on ventilated discs typically involves less frequent rotor replacement due to improved thermal management, though pad wear remains similar across both types. Solid discs, being simpler and more robust, require less complex inspections but tend to experience faster wear and heat-related degradation, necessitating more frequent service intervals.

Impact on Driving Experience and Safety

Ventilated disc brakes offer superior heat dissipation compared to solid discs, reducing brake fade during intense driving conditions and enhancing overall braking performance. This increased thermal management improves driver confidence and safety by maintaining consistent stopping power, especially in high-speed or downhill scenarios. Solid disc brakes, while simpler and often more cost-effective, can overheat more quickly, potentially compromising braking reliability and safety under heavy use.

Conclusion: Selecting the Right Disc for Your Vehicle

Choosing between ventilated and solid disc brakes depends on driving conditions and vehicle performance requirements. Ventilated discs provide superior heat dissipation and enhanced braking efficiency, making them ideal for high-performance or heavy-duty vehicles. Solid discs offer reliable stopping power for everyday driving and are typically more cost-effective and easier to maintain.

ventilated disc vs solid disc Infographic

difterm.com

difterm.com