Single plate clutches offer simplicity, lower cost, and ease of maintenance, making them ideal for everyday passenger vehicles with moderate power requirements. Multi-plate clutches provide higher torque capacity and better heat dissipation, which suits high-performance motorcycles and racing cars. Choosing between them depends on the vehicle's power output, space constraints, and performance demands.

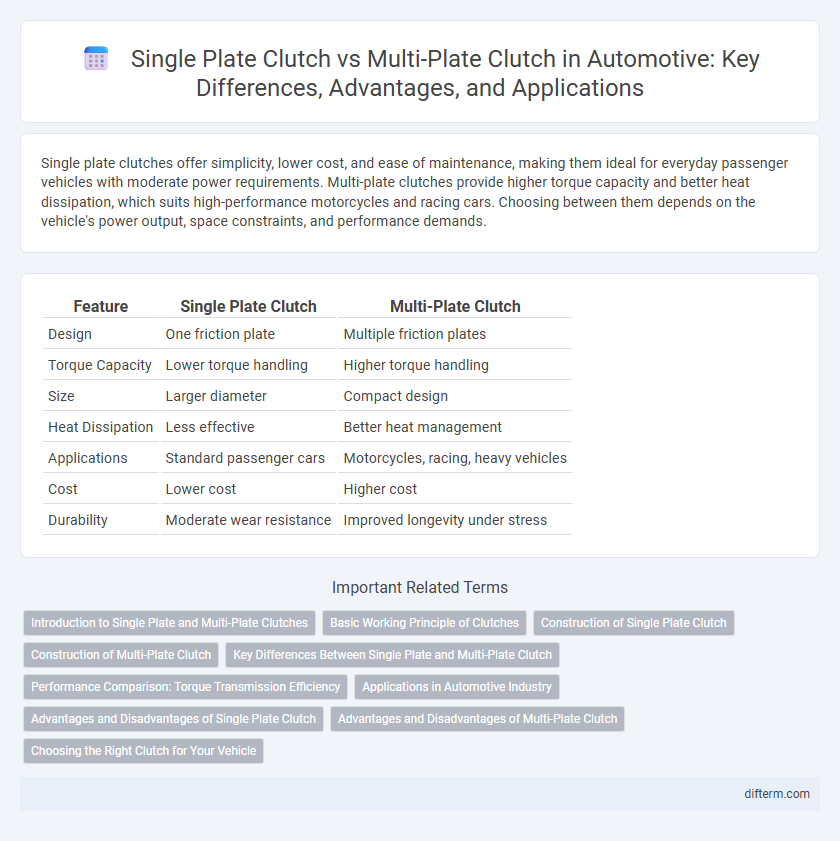

Table of Comparison

| Feature | Single Plate Clutch | Multi-Plate Clutch |

|---|---|---|

| Design | One friction plate | Multiple friction plates |

| Torque Capacity | Lower torque handling | Higher torque handling |

| Size | Larger diameter | Compact design |

| Heat Dissipation | Less effective | Better heat management |

| Applications | Standard passenger cars | Motorcycles, racing, heavy vehicles |

| Cost | Lower cost | Higher cost |

| Durability | Moderate wear resistance | Improved longevity under stress |

Introduction to Single Plate and Multi-Plate Clutches

Single plate clutches feature a single friction disc pressed between the flywheel and pressure plate, offering simplicity and effective torque transfer in most passenger vehicles. Multi-plate clutches incorporate multiple friction discs stacked together, increasing contact surface area to handle higher torque loads in high-performance and heavy-duty applications. The choice between single plate and multi-plate clutches depends on factors such as torque requirements, space constraints, and heat dissipation capabilities.

Basic Working Principle of Clutches

A single plate clutch operates by engaging a single friction disc between the flywheel and pressure plate, transmitting torque from the engine to the transmission through frictional contact. In contrast, a multi-plate clutch uses multiple friction discs stacked together, increasing the contact surface area and allowing higher torque capacity in a compact design. Both clutch types facilitate controlled power transfer, enabling smooth gear shifts and preventing engine stalling during vehicle operation.

Construction of Single Plate Clutch

The construction of a single plate clutch involves a single friction disc sandwiched between the engine flywheel and the pressure plate, secured by coil springs to maintain engagement. The friction disc typically consists of a splined hub connected to the transmission input shaft, ensuring torque transfer through friction material on both sides. This simple yet robust design allows for efficient power transmission with minimal complexity, making it suitable for most passenger vehicles.

Construction of Multi-Plate Clutch

The multi-plate clutch consists of multiple friction plates and steel plates alternately stacked and immersed in oil, providing high torque transmission within a compact design. This construction increases the friction surface area, allowing more torque transfer compared to a single plate clutch while maintaining smooth engagement and durability. The plates are usually splined to the drive and driven shafts, ensuring efficient power transfer in performance and racing vehicles.

Key Differences Between Single Plate and Multi-Plate Clutch

Single plate clutches use a single friction disc, providing simpler design and easier maintenance, ideal for light vehicles with moderate torque requirements. Multi-plate clutches incorporate multiple friction plates, offering higher torque capacity and better heat dissipation, making them suitable for motorcycles and high-performance cars. The choice depends on vehicle weight, power output, and space constraints, with multi-plate clutches delivering improved performance in compact configurations.

Performance Comparison: Torque Transmission Efficiency

Single plate clutches generally offer higher torque transmission efficiency due to their simpler design and lower frictional losses, making them ideal for standard passenger vehicles. Multi-plate clutches provide enhanced torque capacity and better heat dissipation by distributing load across multiple friction surfaces, which is essential for high-performance and heavy-duty automotive applications. The efficiency trade-off in multi-plate clutches arises from increased friction interfaces, but their ability to handle greater torque outweighs the slight reduction in transmission efficiency.

Applications in Automotive Industry

Single plate clutches are commonly used in passenger cars due to their simplicity, cost-effectiveness, and ability to handle moderate torque levels efficiently. Multi-plate clutches find applications in high-performance vehicles, motorcycles, and heavy-duty trucks where increased torque capacity and compact design are essential. The automotive industry leverages single plate clutches for everyday driving scenarios, while multi-plate clutches optimize performance in demanding conditions and racing environments.

Advantages and Disadvantages of Single Plate Clutch

A single plate clutch offers simpler design, lower manufacturing costs, and easier maintenance compared to multi-plate clutches, making it ideal for lightweight passenger vehicles. It provides smooth engagement and effective power transmission at lower torque capacities but struggles with heat dissipation and durability under high-stress conditions. Limited torque handling and potential for slipping during heavy loads are key disadvantages that restrict its use in high-performance or heavy-duty automotive applications.

Advantages and Disadvantages of Multi-Plate Clutch

Multi-plate clutches offer higher torque capacity and better heat dissipation compared to single plate clutches, making them ideal for high-performance and heavy-duty automotive applications. Their compact design allows multiple friction surfaces within a limited space, enhancing power transmission efficiency and reducing wear during intense driving conditions. However, multi-plate clutches tend to be more expensive, complex to maintain, and may generate higher internal friction, potentially leading to quicker wear if not properly managed.

Choosing the Right Clutch for Your Vehicle

Choosing the right clutch for your vehicle depends on factors like power output, driving conditions, and vehicle type. Single plate clutches are ideal for standard passenger cars due to their simplicity, lower cost, and ease of maintenance. Multi-plate clutches offer higher torque capacity, making them suitable for high-performance vehicles, motorcycles, and heavy-duty applications requiring improved heat dissipation and compact design.

single plate clutch vs multi-plate clutch Infographic

difterm.com

difterm.com