Variable valve timing (VVT) enhances engine performance by adjusting the timing of valve opening and closing, optimizing fuel efficiency and power across different RPM ranges. Variable valve lift modifies the height valves open, directly influencing airflow and combustion efficiency for improved torque and responsiveness. Both technologies work together to maximize engine efficiency and adaptability under varying driving conditions.

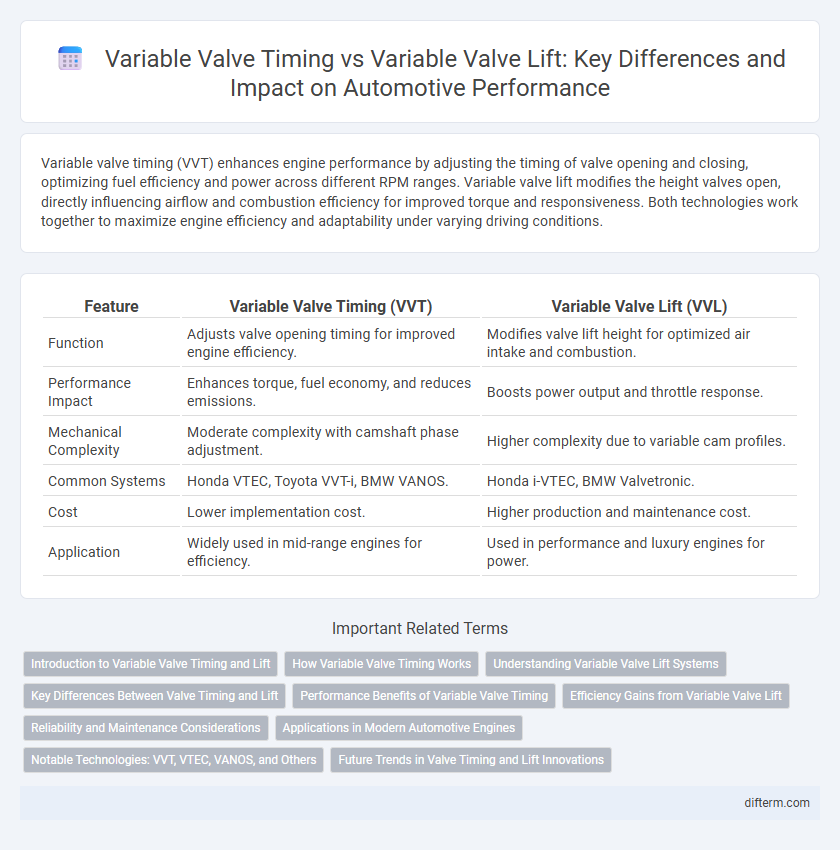

Table of Comparison

| Feature | Variable Valve Timing (VVT) | Variable Valve Lift (VVL) |

|---|---|---|

| Function | Adjusts valve opening timing for improved engine efficiency. | Modifies valve lift height for optimized air intake and combustion. |

| Performance Impact | Enhances torque, fuel economy, and reduces emissions. | Boosts power output and throttle response. |

| Mechanical Complexity | Moderate complexity with camshaft phase adjustment. | Higher complexity due to variable cam profiles. |

| Common Systems | Honda VTEC, Toyota VVT-i, BMW VANOS. | Honda i-VTEC, BMW Valvetronic. |

| Cost | Lower implementation cost. | Higher production and maintenance cost. |

| Application | Widely used in mid-range engines for efficiency. | Used in performance and luxury engines for power. |

Introduction to Variable Valve Timing and Lift

Variable Valve Timing (VVT) and Variable Valve Lift (VVL) technologies optimize engine performance by adjusting valve operation based on driving conditions. VVT modifies the timing of valve opening and closing to enhance power, fuel efficiency, and emissions control, while VVL changes the valve lift height for improved air intake and combustion. Combining these systems allows modern engines to deliver better torque, responsiveness, and reduced fuel consumption across various RPM ranges.

How Variable Valve Timing Works

Variable Valve Timing (VVT) optimizes engine performance by adjusting the timing of valve opening and closing during the combustion cycle, enhancing fuel efficiency and power output. It uses hydraulic actuators controlled by the engine control unit (ECU) to precisely modify camshaft position, allowing valves to open earlier or later based on driving conditions. Unlike variable valve lift systems that alter the valve opening height, VVT focuses solely on timing adjustments to improve torque, reduce emissions, and optimize engine responsiveness.

Understanding Variable Valve Lift Systems

Variable valve lift systems adjust the extent to which engine valves open, enhancing airflow and combustion efficiency beyond the capabilities of traditional variable valve timing, which only controls valve opening duration and timing. By varying valve lift, these systems improve engine performance, fuel economy, and emissions across different RPM ranges. Technologies such as BMW's Valvetronic and Toyota's VVT-iE illustrate how variable valve lift integrates with electronic control for precise, responsive engine management.

Key Differences Between Valve Timing and Lift

Variable valve timing (VVT) primarily adjusts the timing of the valve opening and closing to optimize engine performance across different RPM ranges, improving fuel efficiency and reducing emissions. In contrast, valve lift directly controls the distance the valve opens, influencing the volume of air-fuel mixture entering the combustion chamber, which affects engine power output and torque. The key difference lies in timing modulation versus the extent of valve opening, with VVT enhancing timing dynamics and valve lift focusing on airflow capacity.

Performance Benefits of Variable Valve Timing

Variable valve timing (VVT) enhances engine performance by optimizing valve opening and closing times, resulting in improved power output, fuel efficiency, and reduced emissions. Unlike variable valve lift systems that adjust the valve lift height, VVT continuously modifies timing for better torque delivery across a wide RPM range. This leads to smoother acceleration, increased horsepower, and superior overall engine responsiveness.

Efficiency Gains from Variable Valve Lift

Variable valve timing enhances engine efficiency by precisely controlling the timing of valve opening and closing, optimizing air-fuel mixture intake and exhaust gas expulsion. Variable valve lift further improves efficiency by adjusting the valve lift height, increasing airflow and combustion efficiency under varying load conditions. Together, these technologies reduce fuel consumption and emissions while maximizing engine performance across a broader RPM range.

Reliability and Maintenance Considerations

Variable valve timing systems enhance engine efficiency by optimizing valve opening duration and timing but require precise calibration and quality components to maintain long-term reliability. Variable valve lift mechanisms, while offering improved power and fuel economy, often introduce more complex mechanical parts susceptible to wear, increasing maintenance demands. Choosing between these technologies involves assessing the trade-offs between enhanced performance benefits and potential increases in service intervals and repair costs.

Applications in Modern Automotive Engines

Variable valve timing (VVT) enhances engine efficiency by adjusting the timing of valve opening and closing, optimizing performance across different RPM ranges. Variable valve lift modifies the extent to which valves open, improving air intake control for better combustion and fuel economy. Modern automotive engines often integrate both systems to achieve superior power output, reduced emissions, and improved fuel efficiency under varying driving conditions.

Notable Technologies: VVT, VTEC, VANOS, and Others

Variable valve timing (VVT) technologies such as Honda's VTEC, BMW's VANOS, and Toyota's VVT-i optimize engine performance by adjusting valve timing and lift based on driving conditions. VTEC combines variable timing with variable lift to enhance power output and fuel efficiency, while VANOS primarily focuses on camshaft timing adjustments for improved torque and emissions. These advanced systems enable precise control of valve operation, resulting in better engine responsiveness, reduced fuel consumption, and lower emissions in modern automotive engines.

Future Trends in Valve Timing and Lift Innovations

Emerging trends in automotive valve timing and lift focus on integrating advanced electro-hydraulic and electromagnetic actuators to achieve precise control, enhancing engine efficiency and emissions reduction. Variable valve timing (VVT) systems are evolving toward fully flexible valve actuation, allowing independent adjustment of timing and lift for optimized combustion across diverse driving conditions. Future innovations prioritize real-time adaptive control technologies paired with lightweight materials to improve performance and meet increasingly stringent environmental regulations.

variable valve timing vs lift Infographic

difterm.com

difterm.com