Sequential shift transmissions allow drivers to change gears in a linear, up-or-down sequence, offering faster and more precise gear changes ideal for performance driving. H-pattern shifts require selecting gears based on a traditional manual layout, which gives the driver more control but may result in slower shifts. Enthusiasts favor sequential shifts for racing scenarios due to their efficiency, while H-pattern shifts appeal to those seeking a classic manual driving experience.

Table of Comparison

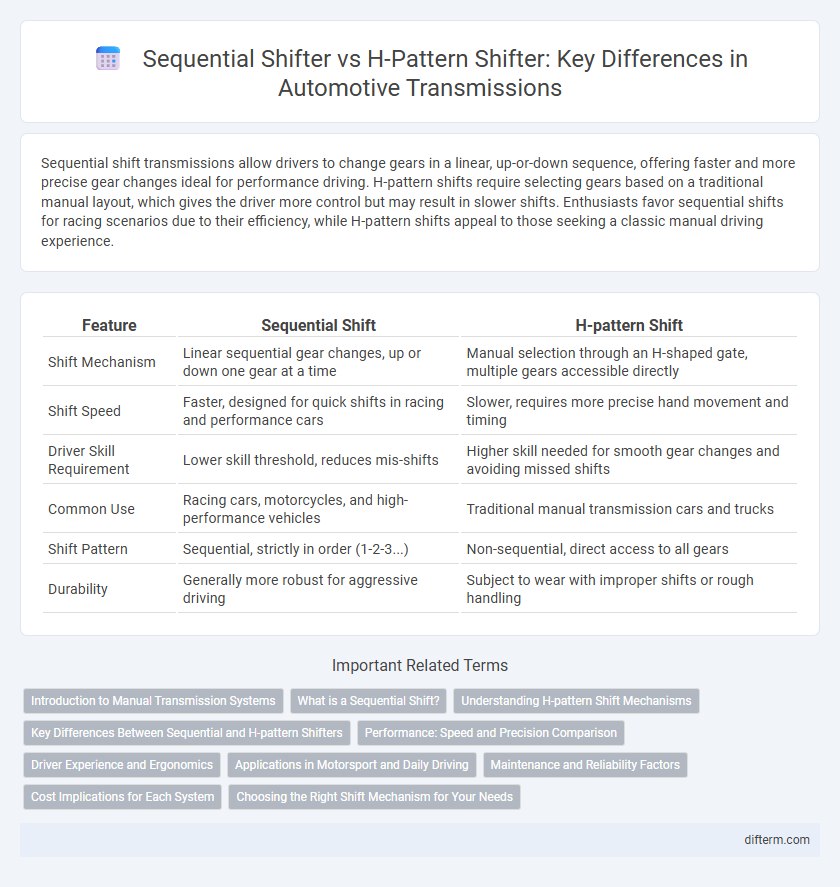

| Feature | Sequential Shift | H-pattern Shift |

|---|---|---|

| Shift Mechanism | Linear sequential gear changes, up or down one gear at a time | Manual selection through an H-shaped gate, multiple gears accessible directly |

| Shift Speed | Faster, designed for quick shifts in racing and performance cars | Slower, requires more precise hand movement and timing |

| Driver Skill Requirement | Lower skill threshold, reduces mis-shifts | Higher skill needed for smooth gear changes and avoiding missed shifts |

| Common Use | Racing cars, motorcycles, and high-performance vehicles | Traditional manual transmission cars and trucks |

| Shift Pattern | Sequential, strictly in order (1-2-3...) | Non-sequential, direct access to all gears |

| Durability | Generally more robust for aggressive driving | Subject to wear with improper shifts or rough handling |

Introduction to Manual Transmission Systems

Manual transmission systems offer two primary shifting mechanisms: sequential shift and H-pattern shift, each designed to optimize gear changes in different driving contexts. Sequential shift allows for rapid, linear gear changes typically favored in racing and high-performance vehicles, enhancing precision and reducing shift times. H-pattern shift, characterized by its traditional gated layout, provides greater control and versatility for everyday driving scenarios, facilitating smoother engagement of gears.

What is a Sequential Shift?

A sequential shift is a transmission system that allows drivers to change gears in a fixed order using a simple push or pull motion, enhancing speed and precision during gear changes. Unlike the traditional H-pattern shift, which requires navigating an H-shaped gate to select gears, the sequential system minimizes shifting errors and reduces shift time, making it ideal for performance and racing vehicles. Commonly found in motorcycles, race cars, and high-performance street cars, sequential gearboxes improve driving dynamics by enabling rapid and consistent gear changes.

Understanding H-pattern Shift Mechanisms

H-pattern shift mechanisms replicate traditional manual transmission layouts, featuring multiple gears arranged in an H-shaped pattern that drivers navigate using a gear stick and clutch pedal. This design allows selective engagement of gears through lateral and vertical movements, requiring precise coordination for smooth transitions. Understanding H-pattern shifts aids in appreciating driver control dynamics and comparing it with the linear, forward-backward movements of sequential shift systems.

Key Differences Between Sequential and H-pattern Shifters

Sequential shifters allow drivers to change gears in a linear, up-or-down motion, enabling quicker and more precise shifts compared to H-pattern shifters, which require manual navigation through an H-shaped gear gate. H-pattern shifters offer more tactile feedback and are common in traditional manual transmissions, while sequential shifters are favored in racing and high-performance vehicles for their speed and efficiency. The key differences include gear engagement method, shift speed, and operational complexity, with sequential shifters providing simplified gear changes and reduced risk of mis-shifting.

Performance: Speed and Precision Comparison

Sequential shift transmissions deliver faster and more precise gear changes compared to H-pattern shifts due to their linear gear selection mechanism and reduced shift throw. This enables performance vehicles to achieve quicker acceleration and smoother power delivery, enhancing overall driving dynamics. H-pattern shifts, while offering more tactile control, generally result in slower shift times and increased risk of missed shifts under high-performance conditions.

Driver Experience and Ergonomics

Sequential shift systems enhance driver experience through faster and more precise gear changes, reducing the effort needed compared to traditional H-pattern shifts. Ergonomically, sequential shifters require less hand movement and offer a more intuitive, linear motion that minimizes driver fatigue during extended driving sessions. In contrast, H-pattern shifts demand greater coordination and repetitive lateral hand motion, which can lead to slower shifts and increased physical strain.

Applications in Motorsport and Daily Driving

Sequential shift transmissions offer faster, more precise gear changes ideal for motorsport applications where split-second timing affects performance and lap times. H-pattern shifts, favored in daily driving, provide greater control and familiarity for drivers, especially in varying traffic conditions and less aggressive driving environments. In racing, sequential gearboxes enhance acceleration and reduce shift errors, while H-pattern gearboxes balance usability and mechanical simplicity in everyday vehicles.

Maintenance and Reliability Factors

Sequential shift transmissions typically offer improved reliability due to fewer moving parts and simpler gear selection mechanisms compared to H-pattern manuals. Maintenance requirements for sequential shifts are generally lower, as the system reduces the risk of missed shifts and gear misalignment, common issues in H-pattern gearboxes. However, H-pattern transmissions may demand more frequent clutch adjustments and pose higher wear risks on synchronizers, impacting long-term maintenance costs.

Cost Implications for Each System

Sequential shift systems typically incur higher initial costs due to advanced mechanical components and electronic integration, making them prevalent in performance and racing vehicles. H-pattern shift systems offer lower manufacturing and maintenance expenses, benefiting budget-conscious automotive markets and entry-level models. Long-term cost implications favor H-pattern shifts for durability and ease of repair, while sequential systems often entail specialized servicing that increases ownership expenses.

Choosing the Right Shift Mechanism for Your Needs

Sequential shift mechanisms offer faster, more precise gear changes ideal for performance driving, while H-pattern shifts provide greater control and familiarity for everyday use. Consider your driving style and vehicle type when selecting between these; sports cars and racing enthusiasts benefit from sequential systems, whereas manual transmission novices or daily drivers may prefer the intuitive H-pattern layout. Evaluating shift speed, ease of use, and mechanical complexity ensures the chosen transmission aligns with your driving requirements and maintenance preferences.

Sequential Shift vs H-pattern Shift Infographic

difterm.com

difterm.com