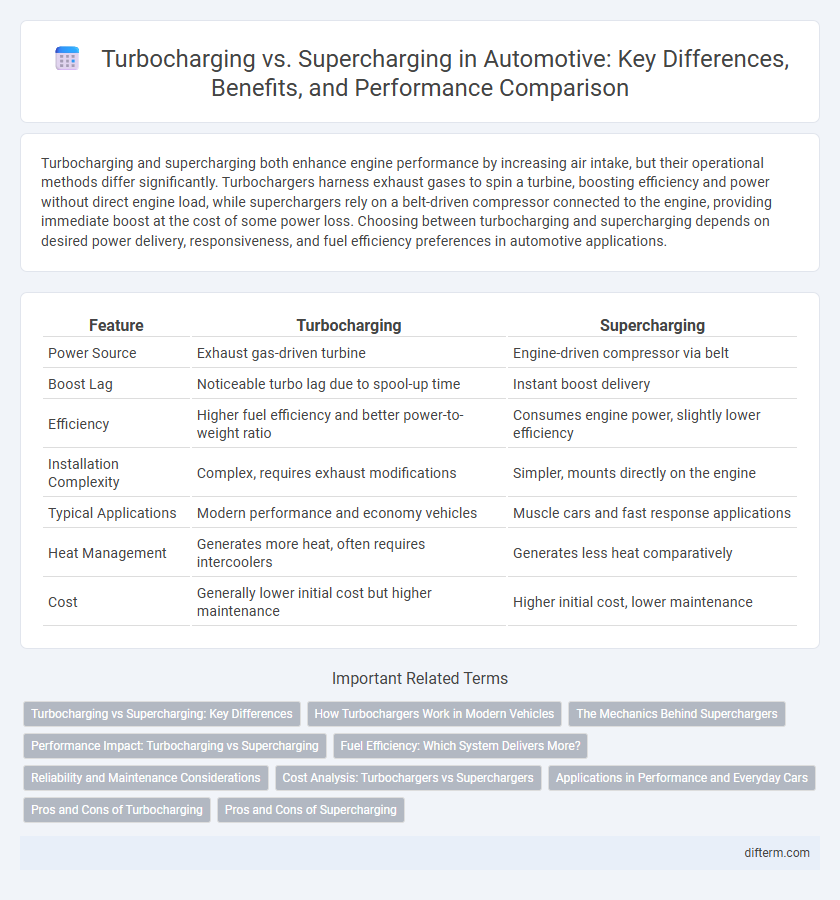

Turbocharging and supercharging both enhance engine performance by increasing air intake, but their operational methods differ significantly. Turbochargers harness exhaust gases to spin a turbine, boosting efficiency and power without direct engine load, while superchargers rely on a belt-driven compressor connected to the engine, providing immediate boost at the cost of some power loss. Choosing between turbocharging and supercharging depends on desired power delivery, responsiveness, and fuel efficiency preferences in automotive applications.

Table of Comparison

| Feature | Turbocharging | Supercharging |

|---|---|---|

| Power Source | Exhaust gas-driven turbine | Engine-driven compressor via belt |

| Boost Lag | Noticeable turbo lag due to spool-up time | Instant boost delivery |

| Efficiency | Higher fuel efficiency and better power-to-weight ratio | Consumes engine power, slightly lower efficiency |

| Installation Complexity | Complex, requires exhaust modifications | Simpler, mounts directly on the engine |

| Typical Applications | Modern performance and economy vehicles | Muscle cars and fast response applications |

| Heat Management | Generates more heat, often requires intercoolers | Generates less heat comparatively |

| Cost | Generally lower initial cost but higher maintenance | Higher initial cost, lower maintenance |

Turbocharging vs Supercharging: Key Differences

Turbocharging utilizes exhaust gas energy to spin a turbine, increasing engine efficiency and power without drawing directly from the crankshaft. Supercharging, in contrast, is driven mechanically by the engine, providing immediate boost but often reducing overall fuel efficiency. Turbochargers typically offer better fuel economy and higher peak power, while superchargers excel in delivering instant throttle response and low-end torque.

How Turbochargers Work in Modern Vehicles

Turbochargers in modern vehicles utilize exhaust gas energy to spin a turbine connected to a compressor, forcing more air into the combustion chamber and significantly increasing engine power and efficiency. This boost in air density enhances combustion, improving fuel economy and reducing emissions compared to naturally aspirated engines. Advanced technologies like variable geometry turbines further optimize performance across different engine speeds, making turbochargers a key component in contemporary automotive design.

The Mechanics Behind Superchargers

Superchargers operate through a belt-driven compressor connected directly to the engine's crankshaft, forcing more air into the combustion chamber to increase engine power. Unlike turbochargers, which use exhaust gases to spin a turbine, superchargers provide immediate boost without lag, enhancing throttle response. The main types of superchargers include Roots, twin-screw, and centrifugal, each with distinct mechanical designs affecting airflow and efficiency.

Performance Impact: Turbocharging vs Supercharging

Turbocharging enhances engine performance by utilizing exhaust gases to spin a turbine, delivering increased air intake and higher power output with improved fuel efficiency. Supercharging directly drives the compressor via the engine's crankshaft, providing immediate boost and linear power delivery but often at the expense of higher fuel consumption. Turbocharging generally results in better overall performance gains under high load conditions, while supercharging offers superior throttle response and low-end torque.

Fuel Efficiency: Which System Delivers More?

Turbocharging enhances fuel efficiency by using exhaust gases to spin a turbine, extracting energy that would otherwise be wasted, resulting in improved engine performance without significantly increasing fuel consumption. Supercharging, driven mechanically by the engine crankshaft, provides immediate power but generally decreases fuel efficiency due to the additional load on the engine. Studies show turbocharged engines can achieve up to 20% better fuel economy compared to supercharged systems under similar driving conditions.

Reliability and Maintenance Considerations

Turbocharging offers higher reliability due to fewer moving parts and reduced mechanical stress compared to supercharging, which relies on belt-driven compressors subject to wear. Maintenance for turbochargers typically involves monitoring oil quality and ensuring proper cooling, whereas superchargers require regular belt replacements and tension adjustments. Selecting between the two depends on balancing performance demands with long-term maintenance costs and reliability expectations in automotive applications.

Cost Analysis: Turbochargers vs Superchargers

Turbochargers typically offer better cost efficiency due to higher fuel economy and cheaper manufacturing components, making them a cost-effective choice for performance enhancement. Superchargers, while often more expensive upfront and less fuel-efficient, provide immediate power delivery without lag, appealing to performance enthusiasts prioritizing responsiveness. Long-term maintenance costs tend to be higher for superchargers because of their mechanical complexity compared to the more compact and durable turbocharger systems.

Applications in Performance and Everyday Cars

Turbocharging enhances engine efficiency and power by utilizing exhaust gases to spin a turbine, making it ideal for performance cars seeking maximum horsepower and fuel economy. Supercharging delivers immediate boost through a belt-driven compressor, providing consistent power and throttle response favored in everyday vehicles requiring smooth acceleration and reliability. Both systems offer distinct advantages tailored to specific driving conditions, with turbochargers dominating high-performance sports cars and superchargers commonly found in muscle cars and practical daily drivers.

Pros and Cons of Turbocharging

Turbocharging enhances engine efficiency by utilizing exhaust gases to increase air intake, resulting in improved power and fuel economy without significant weight increase. However, turbochargers can cause turbo lag, a delay in power delivery, and are more prone to heat buildup, which may require additional cooling systems. Despite these challenges, turbocharging remains a popular choice for balancing performance and emissions in modern automotive engines.

Pros and Cons of Supercharging

Supercharging delivers immediate power gain with improved throttle response due to its direct drive from the engine crankshaft, enhancing low-end torque and overall acceleration. However, it generally causes higher parasitic power loss compared to turbocharging, reducing fuel efficiency and increasing engine load. Maintenance can be more straightforward than turbochargers, but the consistent engine strain may affect long-term durability.

turbocharging vs supercharging Infographic

difterm.com

difterm.com