Regenerative braking captures kinetic energy during deceleration and converts it into electrical energy to recharge the battery, improving overall vehicle efficiency. Friction braking relies on brake pads pressing against rotors to create friction and slow the vehicle, which generates heat and wears components over time. Combining both systems enhances energy recovery while ensuring reliable stopping power and safety in automotive applications.

Table of Comparison

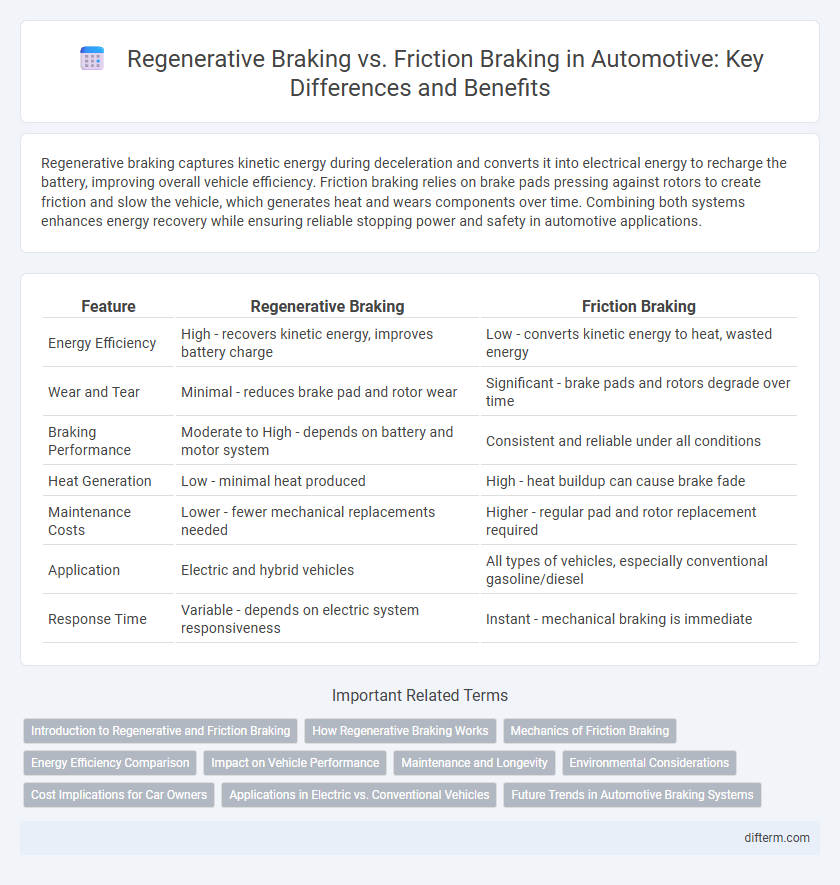

| Feature | Regenerative Braking | Friction Braking |

|---|---|---|

| Energy Efficiency | High - recovers kinetic energy, improves battery charge | Low - converts kinetic energy to heat, wasted energy |

| Wear and Tear | Minimal - reduces brake pad and rotor wear | Significant - brake pads and rotors degrade over time |

| Braking Performance | Moderate to High - depends on battery and motor system | Consistent and reliable under all conditions |

| Heat Generation | Low - minimal heat produced | High - heat buildup can cause brake fade |

| Maintenance Costs | Lower - fewer mechanical replacements needed | Higher - regular pad and rotor replacement required |

| Application | Electric and hybrid vehicles | All types of vehicles, especially conventional gasoline/diesel |

| Response Time | Variable - depends on electric system responsiveness | Instant - mechanical braking is immediate |

Introduction to Regenerative and Friction Braking

Regenerative braking converts kinetic energy into electrical energy, enhancing energy efficiency and extending battery life in electric and hybrid vehicles. Friction braking relies on physical contact between brake pads and rotors to dissipate kinetic energy as heat, offering reliable stopping power but causing wear and energy loss. The integration of both systems optimizes overall braking performance and energy recovery in modern automotive design.

How Regenerative Braking Works

Regenerative braking captures kinetic energy during deceleration and converts it into electrical energy stored in the vehicle's battery, enhancing overall energy efficiency. It uses the electric motor as a generator, reversing its operation to slow the vehicle while recovering energy that would otherwise be lost as heat in friction braking. This process reduces reliance on traditional friction brakes, decreases wear and tear, and extends the driving range of electric and hybrid vehicles.

Mechanics of Friction Braking

Friction braking operates by converting kinetic energy into heat through the contact between brake pads and rotors, relying on mechanical force to slow or stop the vehicle. The mechanics involve hydraulic systems that amplify driver input via brake fluid, activating calipers to press pads against the rotor surface, generating friction. This method ensures immediate and reliable stopping power, particularly effective in emergency braking and low-speed scenarios where regenerative braking may be less efficient.

Energy Efficiency Comparison

Regenerative braking recovers up to 70% of the vehicle's kinetic energy by converting it into electrical energy stored in the battery, significantly enhancing overall energy efficiency compared to friction braking. Friction braking dissipates kinetic energy as heat, resulting in energy loss and increased wear on brake components. Electric and hybrid vehicles utilizing regenerative braking systems can achieve fuel savings of up to 25% by reducing reliance on conventional friction brakes.

Impact on Vehicle Performance

Regenerative braking enhances vehicle efficiency by converting kinetic energy into electrical energy, extending battery life and improving overall fuel economy in electric and hybrid vehicles. In contrast, friction braking provides immediate and reliable stopping power essential for safety but generates heat and wears brake components, leading to higher maintenance costs. Combining both braking systems optimizes performance by balancing energy recovery with effective deceleration and durability.

Maintenance and Longevity

Regenerative braking significantly reduces wear on friction brake components by using the electric motor to decelerate the vehicle, leading to extended maintenance intervals and lower replacement costs. Friction braking relies on mechanical pads and rotors, which require regular inspection and replacement due to wear from heat and friction. Vehicles equipped with regenerative braking systems benefit from enhanced brake longevity and reduced maintenance downtime, improving overall durability and cost-efficiency.

Environmental Considerations

Regenerative braking significantly reduces environmental impact by capturing kinetic energy and converting it into electrical energy, thereby lowering greenhouse gas emissions and energy consumption. In contrast, friction braking relies on mechanical wear and generates particulate matter, contributing to air pollution and increased material waste. Electric and hybrid vehicles benefit the most from regenerative braking systems through enhanced sustainability and extended brake component lifespan.

Cost Implications for Car Owners

Regenerative braking systems reduce wear on traditional friction brake components, leading to lower replacement and maintenance costs for car owners. While initial vehicle costs may be higher due to the advanced technology, long-term savings are realized through improved energy efficiency and decreased brake pad and rotor expenses. Additionally, regenerative braking contributes to extended brake system lifespan, minimizing overall repair costs over the vehicle's lifetime.

Applications in Electric vs. Conventional Vehicles

Regenerative braking in electric vehicles captures kinetic energy during deceleration, converting it into electrical energy stored in the battery, enhancing overall energy efficiency and extending driving range. Conventional vehicles rely primarily on friction braking, which dissipates kinetic energy as heat through brake pads and discs, leading to higher wear and reduced energy recovery. The integration of regenerative braking systems in electric and hybrid vehicles reduces brake wear and maintenance costs compared to traditional friction braking methods used in internal combustion engine cars.

Future Trends in Automotive Braking Systems

Future trends in automotive braking systems emphasize the integration of regenerative braking with advanced friction braking to optimize energy recovery and enhance vehicle efficiency. Emerging technologies, such as intelligent braking control algorithms and enhanced materials for friction components, improve durability and responsiveness while maximizing energy recapture. Electrification and autonomous driving developments drive innovation in braking systems, promoting seamless synergy between mechanical and regenerative braking for increased safety and sustainability.

regenerative braking vs friction braking Infographic

difterm.com

difterm.com