Recirculating ball steering offers greater durability and smoother operation, making it ideal for heavy-duty vehicles like trucks and SUVs. Rack-and-pinion steering provides precise handling and quicker response, favored in passenger cars and performance vehicles. Choosing between the two depends on the desired balance of strength and steering precision in automotive applications.

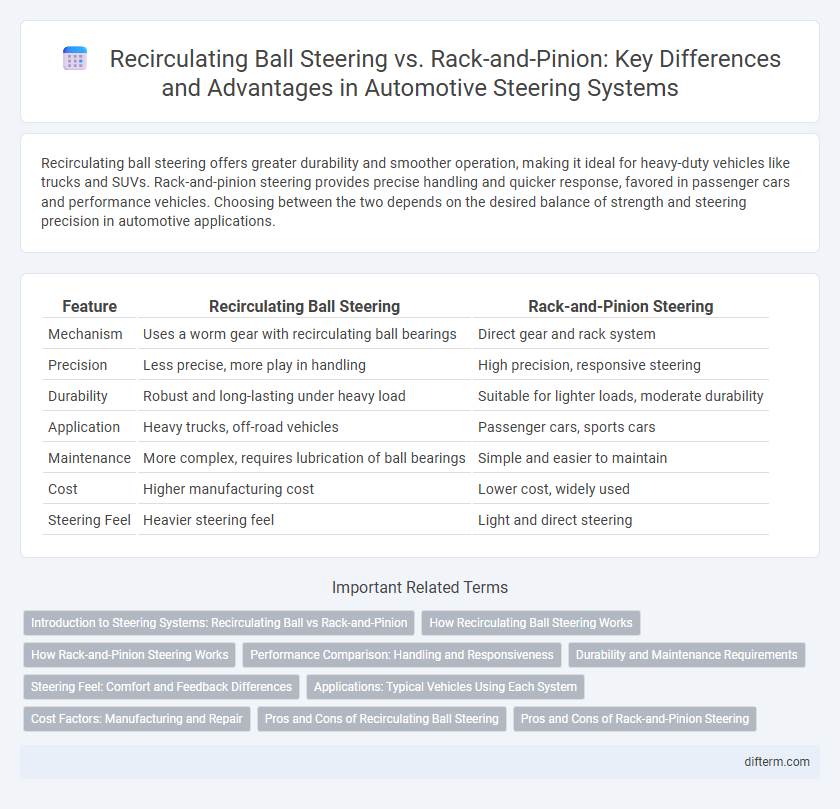

Table of Comparison

| Feature | Recirculating Ball Steering | Rack-and-Pinion Steering |

|---|---|---|

| Mechanism | Uses a worm gear with recirculating ball bearings | Direct gear and rack system |

| Precision | Less precise, more play in handling | High precision, responsive steering |

| Durability | Robust and long-lasting under heavy load | Suitable for lighter loads, moderate durability |

| Application | Heavy trucks, off-road vehicles | Passenger cars, sports cars |

| Maintenance | More complex, requires lubrication of ball bearings | Simple and easier to maintain |

| Cost | Higher manufacturing cost | Lower cost, widely used |

| Steering Feel | Heavier steering feel | Light and direct steering |

Introduction to Steering Systems: Recirculating Ball vs Rack-and-Pinion

Recirculating ball steering systems use a worm gear mechanism with ball bearings to reduce friction and enhance durability, commonly found in heavy-duty trucks and older vehicles. Rack-and-pinion steering converts rotational motion into linear motion via a gearset directly connected to the steering shaft, offering precise handling and responsiveness favored in modern passenger cars. Understanding the differences in design, efficiency, and application helps optimize vehicle performance and driver control.

How Recirculating Ball Steering Works

Recirculating ball steering operates by using a worm gear inside the steering box, where ball bearings circulate between the worm gear and the sector shaft to reduce friction and wear. This mechanism translates the rotational movement of the steering wheel into the lateral movement needed to turn the vehicle's wheels, providing precise control and durability for heavy-duty and off-road vehicles. Compared to rack-and-pinion systems, recirculating ball steering excels in handling higher steering loads and offers smoother operation in commercial trucks and SUVs.

How Rack-and-Pinion Steering Works

Rack-and-pinion steering converts the rotational motion of the steering wheel into linear motion to turn the vehicle's wheels with precision. A pinion gear meshes with a linear rack, translating the driver's input directly to the steering linkage, resulting in responsive handling and reduced play. This system is favored in modern cars for its compact design, lightweight construction, and efficient power steering integration.

Performance Comparison: Handling and Responsiveness

Recirculating ball steering offers robust durability and smoother feedback in heavy-duty vehicles, but rack-and-pinion systems provide superior handling precision and quicker responsiveness, making them ideal for performance cars. Rack-and-pinion steering translates driver input more directly to the wheels, enhancing cornering accuracy and driving experience. The simplicity and reduced play in rack-and-pinion designs result in faster response times compared to the more complex recirculating ball mechanism.

Durability and Maintenance Requirements

Recirculating ball steering systems offer enhanced durability due to their robust construction and ability to handle heavier loads, making them ideal for trucks and larger vehicles. Maintenance requirements for recirculating ball systems are generally higher given the complexity and number of moving parts, which may necessitate more frequent inspections and potential adjustments. In contrast, rack-and-pinion steering provides simpler maintenance with fewer components, but may experience faster wear in high-stress conditions, making it more suitable for passenger cars where precision and low maintenance are prioritized.

Steering Feel: Comfort and Feedback Differences

Recirculating ball steering provides a robust, heavier steering feel ideal for trucks and larger vehicles, offering increased durability but less precise feedback compared to rack-and-pinion systems. Rack-and-pinion steering delivers sharper, more responsive handling favored in passenger cars, enhancing driver comfort through direct road feel and quicker adjustments. The difference in steering feedback impacts driving experience, with rack-and-pinion optimizing precision and recirculating ball prioritizing smoothness and strength.

Applications: Typical Vehicles Using Each System

Recirculating ball steering systems are commonly found in heavy-duty trucks, SUVs, and off-road vehicles due to their durability and ability to handle high torque loads. Rack-and-pinion steering dominates passenger cars, sports cars, and compact vehicles because of its precise control and lighter weight. Commercial vehicles and large SUVs prioritize recirculating ball systems for robustness, while most sedans and performance vehicles favor rack-and-pinion for responsiveness and efficiency.

Cost Factors: Manufacturing and Repair

Recirculating ball steering systems generally have higher manufacturing costs due to their complex components and precision machining requirements, while rack-and-pinion systems benefit from simpler design and mass production economies. Repair expenses for recirculating ball steering tend to be greater because of specialized parts and more labor-intensive servicing compared to the relatively straightforward and cost-effective maintenance of rack-and-pinion setups. These cost factors significantly influence vehicle pricing and long-term ownership expenses in the automotive industry.

Pros and Cons of Recirculating Ball Steering

Recirculating ball steering offers superior durability and is well-suited for heavy-duty vehicles due to its robust design that reduces friction and wear between moving parts. This system provides better feedback at low speeds and can handle larger loads, making it ideal for trucks and off-road vehicles. However, it tends to be less precise and heavier than rack-and-pinion steering, resulting in slower steering response and more complex maintenance.

Pros and Cons of Rack-and-Pinion Steering

Rack-and-pinion steering offers precise handling and a direct steering feel, making it ideal for performance and passenger vehicles. It is compact and lightweight, contributing to improved fuel efficiency and easier integration into modern vehicle designs. However, it may be less durable under heavy-duty use and more susceptible to wear in harsh off-road conditions compared to recirculating ball systems.

recirculating ball steering vs rack-and-pinion Infographic

difterm.com

difterm.com