Global automotive platforms enable manufacturers to standardize production, reduce costs, and streamline supply chains across multiple markets, achieving economies of scale. Regional platforms, however, allow for tailored vehicle designs that cater specifically to local consumer preferences, regulatory requirements, and climatic conditions. Balancing global efficiency with regional customization is essential for automotive companies aiming to optimize product appeal and operational flexibility.

Table of Comparison

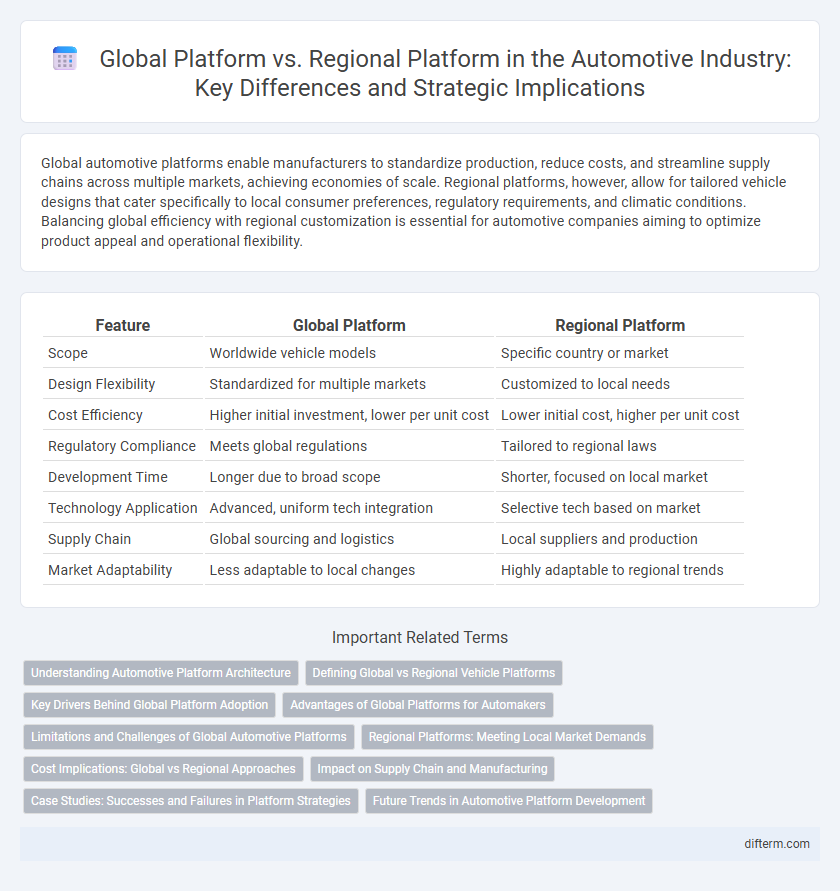

| Feature | Global Platform | Regional Platform |

|---|---|---|

| Scope | Worldwide vehicle models | Specific country or market |

| Design Flexibility | Standardized for multiple markets | Customized to local needs |

| Cost Efficiency | Higher initial investment, lower per unit cost | Lower initial cost, higher per unit cost |

| Regulatory Compliance | Meets global regulations | Tailored to regional laws |

| Development Time | Longer due to broad scope | Shorter, focused on local market |

| Technology Application | Advanced, uniform tech integration | Selective tech based on market |

| Supply Chain | Global sourcing and logistics | Local suppliers and production |

| Market Adaptability | Less adaptable to local changes | Highly adaptable to regional trends |

Understanding Automotive Platform Architecture

Global automotive platforms standardize core vehicle architectures to enhance economies of scale, streamline production, and ensure consistent quality across multiple markets. Regional platforms are tailored to address specific consumer preferences, regulatory requirements, and environmental conditions unique to local markets. Understanding the balance between global and regional platform architectures enables manufacturers to optimize cost efficiency while meeting diverse market demands.

Defining Global vs Regional Vehicle Platforms

Global vehicle platforms are engineered to support a wide range of models across multiple markets, enabling cost savings through standardized components and streamlined production processes. Regional platforms are tailored to specific markets or consumer preferences, optimizing design and features to meet local regulations, climate conditions, and cultural demands. Manufacturers balance global and regional platforms to achieve economies of scale while addressing regional variations in safety standards, emission controls, and market expectations.

Key Drivers Behind Global Platform Adoption

Global platforms in the automotive industry are primarily driven by the need for cost efficiency through economies of scale, allowing manufacturers to standardize components and reduce production expenses across multiple markets. Enhanced technological integration and faster time-to-market for new vehicle models also contribute to the widespread adoption of global platforms. Manufacturers benefit from streamlined supply chains and improved global brand consistency, which regional platforms struggle to achieve due to localized customization and varying regulatory requirements.

Advantages of Global Platforms for Automakers

Global automotive platforms enable automakers to streamline production by standardizing components, reducing manufacturing costs through economies of scale. They facilitate faster development cycles and enhance vehicle quality consistency across markets. Leveraging global platforms supports automakers in meeting diverse regulatory requirements efficiently while expanding their market reach worldwide.

Limitations and Challenges of Global Automotive Platforms

Global automotive platforms face limitations such as high development costs and complex regulatory compliance across diverse markets. Differences in regional customer preferences and infrastructure require significant platform customization, reducing economies of scale. Supply chain coordination and local sourcing challenges further complicate the efficient production and deployment of global platforms.

Regional Platforms: Meeting Local Market Demands

Regional automotive platforms prioritize customization to address specific regulatory requirements, climate conditions, and consumer preferences unique to each market. By leveraging local supply chains and manufacturing capabilities, these platforms enhance cost efficiency and accelerate time-to-market. This targeted approach improves customer satisfaction and supports competitive differentiation in diverse global markets.

Cost Implications: Global vs Regional Approaches

Global automotive platforms leverage economies of scale by standardizing components, which reduces manufacturing and development costs across multiple markets. Regional platforms often incur higher expenses due to tailored designs and localized supply chains that address specific market preferences and regulations. Balancing global platform efficiencies with regional customization challenges remains critical for optimizing overall cost structures in the automotive industry.

Impact on Supply Chain and Manufacturing

Global platforms streamline automotive supply chains by enabling standardized components and processes across multiple markets, reducing production costs and lead times. Regional platforms cater to local preferences and regulations, which can increase complexity in supply chain management and manufacturing due to varied parts and assembly procedures. Balancing global platform efficiency with regional customization impacts inventory management, supplier coordination, and production flexibility in the automotive industry.

Case Studies: Successes and Failures in Platform Strategies

Case studies reveal that global automotive platforms, such as Volkswagen's MQB, deliver cost efficiency and streamlined production across multiple markets, while regional platforms like Toyota's TNGA adapt better to local consumer preferences and regulatory standards. Successes hinge on balancing scale economies with market-specific customization, but failures often arise from overstandardization or underestimating regional requirements, as seen in GM's struggles with its global Delta platform. Understanding these dynamics helps manufacturers optimize platform strategies to enhance competitiveness and innovation in diverse global markets.

Future Trends in Automotive Platform Development

Global automotive platforms are increasingly designed with modular architectures to accommodate diverse market regulations and consumer preferences, enabling scalable production and reduced costs. Regional platforms emphasize localized customization, integrating specific safety standards, climate adaptations, and infotainment preferences to enhance market relevance. Future trends point to hybrid strategies combining global scalability with regional flexibility, supported by advanced digital engineering tools and AI-driven design optimization.

global platform vs regional platform Infographic

difterm.com

difterm.com