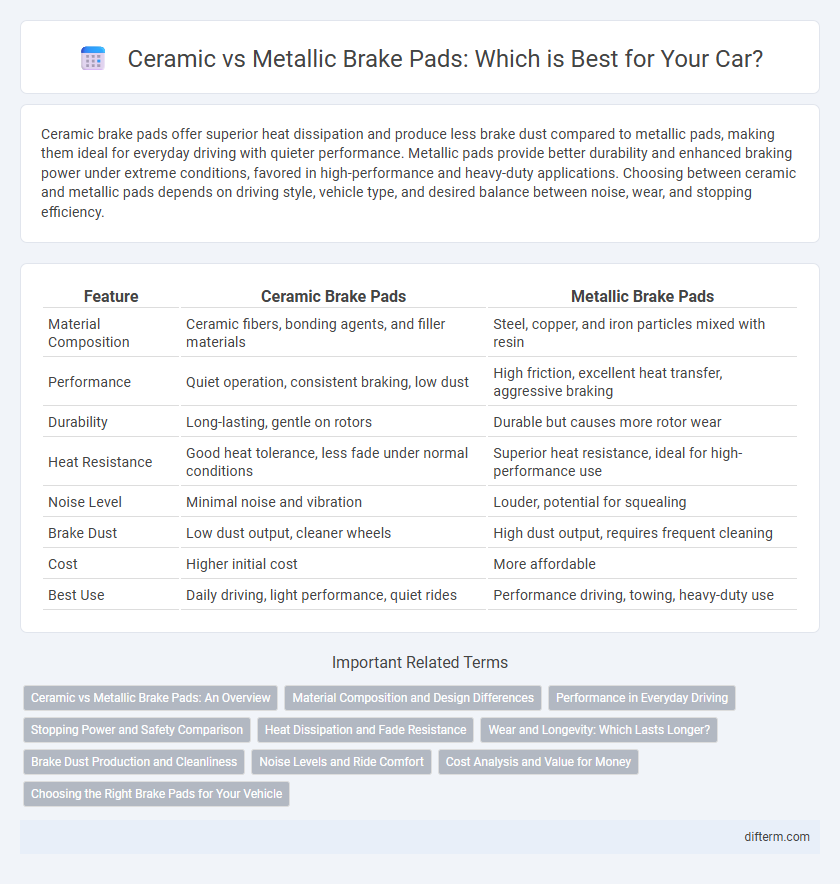

Ceramic brake pads offer superior heat dissipation and produce less brake dust compared to metallic pads, making them ideal for everyday driving with quieter performance. Metallic pads provide better durability and enhanced braking power under extreme conditions, favored in high-performance and heavy-duty applications. Choosing between ceramic and metallic pads depends on driving style, vehicle type, and desired balance between noise, wear, and stopping efficiency.

Table of Comparison

| Feature | Ceramic Brake Pads | Metallic Brake Pads |

|---|---|---|

| Material Composition | Ceramic fibers, bonding agents, and filler materials | Steel, copper, and iron particles mixed with resin |

| Performance | Quiet operation, consistent braking, low dust | High friction, excellent heat transfer, aggressive braking |

| Durability | Long-lasting, gentle on rotors | Durable but causes more rotor wear |

| Heat Resistance | Good heat tolerance, less fade under normal conditions | Superior heat resistance, ideal for high-performance use |

| Noise Level | Minimal noise and vibration | Louder, potential for squealing |

| Brake Dust | Low dust output, cleaner wheels | High dust output, requires frequent cleaning |

| Cost | Higher initial cost | More affordable |

| Best Use | Daily driving, light performance, quiet rides | Performance driving, towing, heavy-duty use |

Ceramic vs Metallic Brake Pads: An Overview

Ceramic brake pads offer quieter operation and produce less brake dust compared to metallic brake pads, enhancing overall vehicle cleanliness. Metallic brake pads provide superior performance under high-temperature conditions, making them ideal for heavy-duty and high-performance driving. The choice between ceramic and metallic brake pads depends on driving habits, braking performance needs, and budget considerations.

Material Composition and Design Differences

Ceramic brake pads consist of dense ceramic fibers, bonding agents, and small amounts of metal, providing quieter operation and less brake dust compared to metallic pads. Metallic brake pads are made from a mixture of metals like copper, steel, iron, and graphite, offering superior heat dissipation and enhanced stopping power under extreme conditions. The design of ceramic pads emphasizes longevity and low noise, while metallic pads prioritize durability and performance in heavy-duty or high-temperature environments.

Performance in Everyday Driving

Ceramic brake pads deliver quieter, smoother stops with minimal brake dust, enhancing everyday driving comfort and maintenance. Metallic pads offer superior heat dissipation and durability, providing consistent performance under heavier loads or spirited driving conditions. For typical daily commutes and city driving, ceramic pads balance effective stopping power with low wear on rotors.

Stopping Power and Safety Comparison

Ceramic brake pads offer superior stopping power with consistent performance under varied temperature conditions, enhancing overall vehicle safety by reducing fade during prolonged braking. Metallic pads provide excellent heat dissipation and durability, which contributes to reliable stopping power in high-performance or heavy-duty driving scenarios. Prioritizing safety, ceramic pads generate less brake dust and noise, helping maintain cleaner wheels and better brake system function over time.

Heat Dissipation and Fade Resistance

Ceramic brake pads offer superior heat dissipation compared to metallic pads due to their advanced composite materials that maintain stable friction levels under high temperatures. Metallic pads, while durable, tend to retain more heat, increasing the risk of brake fade during prolonged or aggressive braking. Enhanced fade resistance in ceramic pads ensures consistent braking performance and safety, especially in demanding driving conditions.

Wear and Longevity: Which Lasts Longer?

Ceramic brake pads offer superior wear resistance and longer lifespan compared to metallic pads due to their harder, heat-resistant composite materials. Metallic pads tend to wear down faster under high-stress conditions because of their softer metal alloys, leading to more frequent replacements. Choosing ceramic pads reduces maintenance costs by providing consistent performance and extended durability in automotive braking systems.

Brake Dust Production and Cleanliness

Ceramic brake pads produce significantly less brake dust compared to metallic pads, resulting in cleaner wheels and reduced maintenance. Their fine, non-metallic particles do not cling to surfaces or cause discoloration, enhancing overall vehicle appearance. In contrast, metallic pads generate coarser, darker dust that accumulates rapidly and is tougher to clean.

Noise Levels and Ride Comfort

Ceramic brake pads generate significantly less noise than metallic pads due to their composition, which reduces vibrations during braking. They also enhance ride comfort by producing smoother, quieter stops and minimizing brake dust that can degrade wheel appearance and contribute to noise. Metallic pads tend to create more noise and a harsher ride feel, especially under heavy braking conditions.

Cost Analysis and Value for Money

Ceramic brake pads typically cost 20-30% more than metallic pads but offer longer lifespan and quieter operation, reducing overall maintenance expenses. Metallic pads provide better initial braking performance and are more budget-friendly, making them ideal for cost-conscious consumers seeking short-term savings. Evaluating total cost of ownership, ceramic pads deliver better value for money through extended durability and less rotor wear, despite higher upfront costs.

Choosing the Right Brake Pads for Your Vehicle

Choosing the right brake pads for your vehicle involves understanding the performance differences between ceramic pads and metallic pads. Ceramic brake pads offer quieter operation, less brake dust, and a longer lifespan, making them ideal for everyday driving and light-duty use. Metallic pads provide superior heat dissipation and enhanced stopping power, which is essential for heavy-duty applications and high-performance vehicles.

ceramic pads vs metallic pads Infographic

difterm.com

difterm.com