Ladder frame chassis offer superior durability and easier repair, making them ideal for heavy-duty automotive pets, while monocoque structures provide enhanced rigidity and better crash safety due to their integrated body design. The ladder frame's separate body and frame allow for greater flexibility in modifications, whereas monocoque designs reduce overall vehicle weight and improve fuel efficiency. Choosing between ladder frame and monocoque depends on the automotive pet's intended use, balancing strength and performance needs.

Table of Comparison

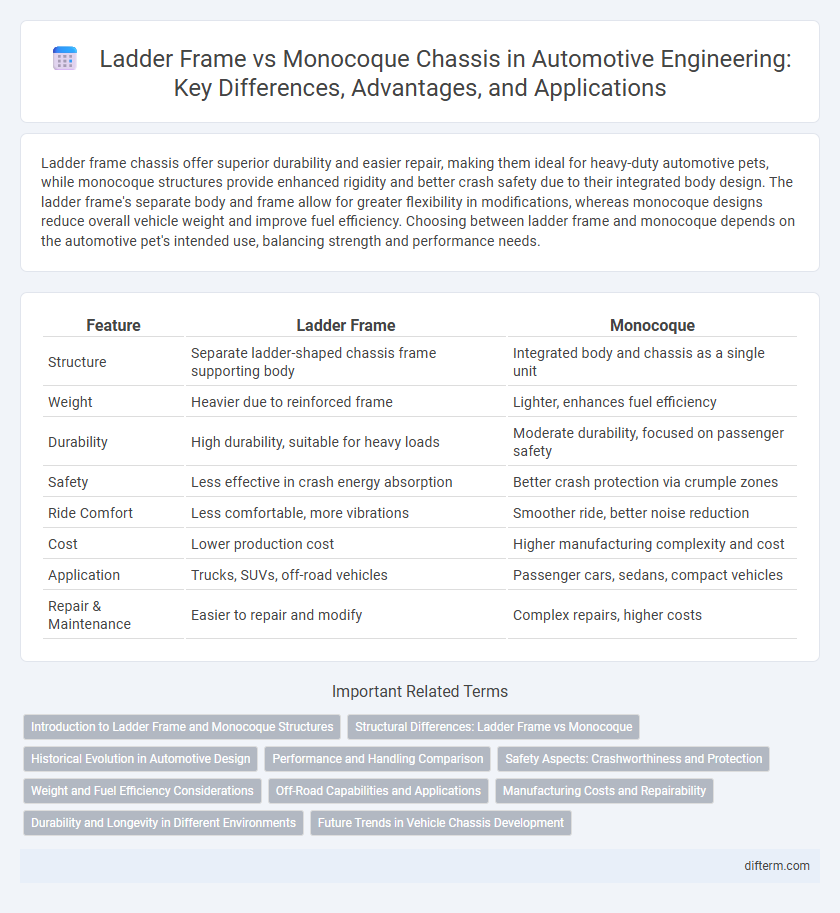

| Feature | Ladder Frame | Monocoque |

|---|---|---|

| Structure | Separate ladder-shaped chassis frame supporting body | Integrated body and chassis as a single unit |

| Weight | Heavier due to reinforced frame | Lighter, enhances fuel efficiency |

| Durability | High durability, suitable for heavy loads | Moderate durability, focused on passenger safety |

| Safety | Less effective in crash energy absorption | Better crash protection via crumple zones |

| Ride Comfort | Less comfortable, more vibrations | Smoother ride, better noise reduction |

| Cost | Lower production cost | Higher manufacturing complexity and cost |

| Application | Trucks, SUVs, off-road vehicles | Passenger cars, sedans, compact vehicles |

| Repair & Maintenance | Easier to repair and modify | Complex repairs, higher costs |

Introduction to Ladder Frame and Monocoque Structures

Ladder frame structures consist of two longitudinal beams connected by several cross members, providing robust support and durability, primarily used in trucks and SUVs for off-road performance. Monocoque structures integrate the body and chassis into a single unit, enhancing vehicle rigidity and reducing weight, which improves fuel efficiency and handling in passenger cars. The choice between ladder frame and monocoque designs significantly impacts vehicle strength, safety, and weight distribution.

Structural Differences: Ladder Frame vs Monocoque

Ladder frame structures consist of two longitudinal beams connected by multiple cross members, providing high rigidity and durability ideal for heavy-duty vehicles and off-road applications. Monocoque designs integrate the body and chassis into a single shell, enhancing overall stiffness, reducing weight, and improving fuel efficiency in passenger cars. The structural difference impacts crash safety, vehicle weight distribution, and manufacturing complexity, with ladder frames favoring strength and repairability while monocoque emphasizes lightweight construction and dynamic performance.

Historical Evolution in Automotive Design

Ladder frame chassis dominated early automotive design due to its simplicity and robustness, particularly favored in trucks and off-road vehicles since the late 19th century. The evolution towards monocoque construction began in the 1930s with advancements in steel stamping and welding, leading to lighter, more rigid vehicles that improved performance and fuel efficiency. By the late 20th century, monocoque frames became the industry standard in passenger cars, reflecting a shift towards integrated structural design and enhanced safety features.

Performance and Handling Comparison

Ladder frame chassis offer superior durability and off-road performance due to their rigid construction but typically result in heavier vehicles with less precise handling. Monocoque designs provide improved handling and ride comfort by integrating the body and frame, reducing weight and enhancing structural stiffness. Performance-wise, monocoque vehicles excel in on-road agility and fuel efficiency, while ladder frames dominate in load-bearing capacity and toughness for rugged conditions.

Safety Aspects: Crashworthiness and Protection

Ladder frame chassis offer superior impact resistance in heavy-duty collisions due to their robust, separate frame structure, effectively absorbing and dissipating crash forces. Monocoque designs integrate the body and frame, enabling advanced crumple zones that enhance occupant protection by systematically deforming to reduce impact energy transfer. Modern automotive safety standards favor monocoque construction for passenger vehicles, given its optimized crashworthiness through engineered deformation and advanced materials.

Weight and Fuel Efficiency Considerations

Ladder frame chassis are typically heavier than monocoque designs, which increases the vehicle's overall weight and reduces fuel efficiency. Monocoque frames integrate the body and chassis into a single structure, significantly lowering weight and enhancing fuel economy by improving aerodynamics and reducing drag. Choosing monocoque construction is more beneficial for lightweight vehicles aiming for higher miles per gallon and reduced emissions.

Off-Road Capabilities and Applications

Ladder frame chassis offer superior off-road capabilities due to their robust construction and high torsional rigidity, making them ideal for heavy-duty vehicles like trucks and SUVs used in rugged terrains. Monocoque chassis, while lighter and more efficient for on-road performance, typically lack the structural strength required for extreme off-road applications. Off-road enthusiasts and manufacturers prioritize ladder frames for enhanced durability, ease of repair, and better handling of harsh impacts and uneven surfaces.

Manufacturing Costs and Repairability

Ladder frame construction generally incurs higher manufacturing costs due to the extensive use of heavy steel components and complex welding processes compared to monocoque designs that utilize lighter, integrated materials for streamlined assembly. Repairability favors ladder frames as their separate chassis and body structure allows for easier replacement of damaged parts without compromising overall integrity, whereas monocoque vehicles often require specialized repair techniques and higher expenditures due to their unified construction. The choice between ladder frame and monocoque impacts overall lifecycle expenses, balancing initial production investment against long-term maintenance and repair efficiency.

Durability and Longevity in Different Environments

Ladder frame chassis offer superior durability and longevity in harsh off-road and heavy-duty conditions due to their robust construction and ability to absorb impacts without compromising structural integrity. Monocoque designs excel in regular urban and highway environments, providing enhanced corrosion resistance and better structural rigidity that contributes to longer lifespan under typical driving stresses. Choosing between ladder frame and monocoque depends on environmental exposure and usage, with ladder frames favoring extreme terrains and monocoques thriving in controlled, paved conditions.

Future Trends in Vehicle Chassis Development

Future trends in vehicle chassis development emphasize lightweight monocoque structures integrated with advanced materials like carbon fiber and high-strength aluminum alloys to enhance fuel efficiency and crash safety. Ladder frame chassis continue to evolve with modular designs and hybrid materials tailored for electric and heavy-duty vehicles, optimizing durability and load capacity. Emerging technologies such as 3D printing and smart sensors are revolutionizing chassis manufacturing and real-time structural health monitoring, accelerating innovation in automotive engineering.

ladder frame vs monocoque Infographic

difterm.com

difterm.com