Tire siping involves cutting thin slits into the tread blocks to enhance traction on wet or icy surfaces by improving water evacuation and increasing grip. Tire grooving, on the other hand, refers to the deeper channels molded or cut into the tread that help channel larger volumes of water away from the tire's contact patch, reducing hydroplaning. Both techniques work together to improve overall tire performance and safety in diverse driving conditions.

Table of Comparison

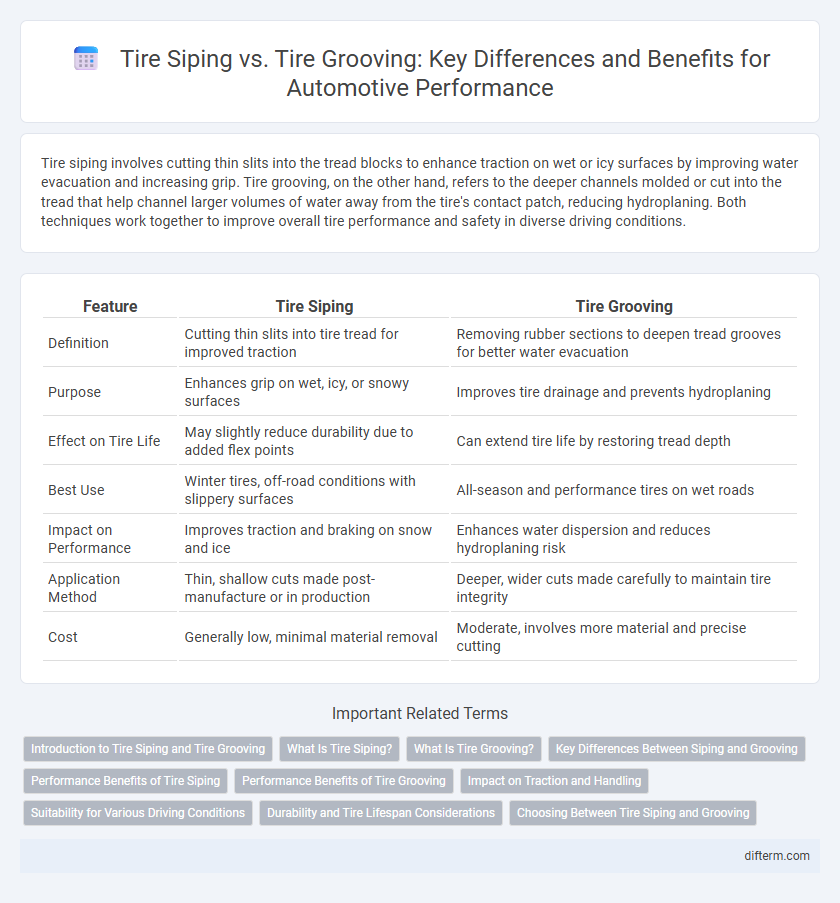

| Feature | Tire Siping | Tire Grooving |

|---|---|---|

| Definition | Cutting thin slits into tire tread for improved traction | Removing rubber sections to deepen tread grooves for better water evacuation |

| Purpose | Enhances grip on wet, icy, or snowy surfaces | Improves tire drainage and prevents hydroplaning |

| Effect on Tire Life | May slightly reduce durability due to added flex points | Can extend tire life by restoring tread depth |

| Best Use | Winter tires, off-road conditions with slippery surfaces | All-season and performance tires on wet roads |

| Impact on Performance | Improves traction and braking on snow and ice | Enhances water dispersion and reduces hydroplaning risk |

| Application Method | Thin, shallow cuts made post-manufacture or in production | Deeper, wider cuts made carefully to maintain tire integrity |

| Cost | Generally low, minimal material removal | Moderate, involves more material and precise cutting |

Introduction to Tire Siping and Tire Grooving

Tire siping involves cutting thin slits across tire tread blocks to improve traction by increasing the number of biting edges, which enhances grip on wet, icy, or slippery surfaces. Tire grooving refers to the creation of deeper, wider channels in the tread pattern designed to efficiently evacuate water, reduce hydroplaning, and maintain stability at high speeds. Both siping and grooving are crucial tread design features that optimize performance, safety, and handling in various driving conditions.

What Is Tire Siping?

Tire siping involves cutting thin slits across the tread surface to enhance traction and flexibility, especially on wet or icy roads. This process increases the number of biting edges, improving grip and reducing hydroplaning risk. Compared to tire grooving, siping targets finer, more numerous cuts, optimizing performance without significantly affecting tread depth or tire durability.

What Is Tire Grooving?

Tire grooving involves cutting deep channels into the tread of a tire to enhance water evacuation and improve traction on wet surfaces. These grooves increase grip by allowing water to escape from beneath the tire, reducing hydroplaning risks. Grooving is essential for maintaining optimal performance, especially in wet or slippery driving conditions.

Key Differences Between Siping and Grooving

Tire siping involves cutting thin slits across the tread to enhance traction on wet or icy surfaces by improving water evacuation and increasing grip. Tire grooving refers to the deeper, wider channels molded or cut into the tread, designed primarily to channel water away and prevent hydroplaning. Key differences include siping's focus on fine surface traction versus grooving's role in water displacement and tread pattern design.

Performance Benefits of Tire Siping

Tire siping enhances traction by creating additional biting edges that improve grip on wet, icy, or slippery surfaces, boosting vehicle stability and braking performance. Unlike tire grooving, which channels water away from the tire surface, siping increases flexibility in the tread, allowing better adaptation to road irregularities and reducing hydroplaning risk. This results in improved overall handling and safety in diverse driving conditions.

Performance Benefits of Tire Grooving

Tire grooving enhances traction by improving water evacuation, reducing hydroplaning risks on wet surfaces. Deeper and wider grooves provide better grip on snow and mud, contributing to superior all-terrain performance. This design also aids in maintaining tire coolness by increasing airflow, leading to longer tire life and consistent handling.

Impact on Traction and Handling

Tire siping enhances traction on wet and icy surfaces by creating additional biting edges that improve grip and water evacuation. Tire grooving primarily improves water channeling and hydroplaning resistance, providing stability and handling in wet conditions. Combining siping and grooving optimizes overall tire performance by balancing traction on varied surfaces and maintaining responsive handling.

Suitability for Various Driving Conditions

Tire siping enhances traction on wet, icy, and snowy roads by increasing the number of biting edges, making it ideal for slippery conditions and winter driving. Tire grooving improves water evacuation and mud dispersion, which enhances performance on wet surfaces and off-road terrains. Both techniques optimize safety and handling but are suited to distinct environments: siping for low-traction roads and grooving for water and debris clearance.

Durability and Tire Lifespan Considerations

Tire siping enhances grip by creating small slits that improve traction on wet and icy surfaces, but these fine cuts can reduce tire durability due to increased tread flexibility and wear. Tire grooving involves deeper, wider channels that efficiently evacuate water and debris, contributing to longer tire lifespan by maintaining structural integrity under stress. Prioritizing tire grooving over siping can result in improved durability and extended tire lifespan, especially in demanding driving conditions.

Choosing Between Tire Siping and Grooving

Choosing between tire siping and grooving depends on the specific driving conditions and performance needs. Tire siping enhances traction on wet, icy, or snowy surfaces by creating additional biting edges, while grooving improves water evacuation and stability on wet roads by channeling water away from the contact patch. For maximum safety and performance, consider the tire's primary application, whether it's all-season driving, winter conditions, or high-performance handling.

tire siping vs tire grooving Infographic

difterm.com

difterm.com