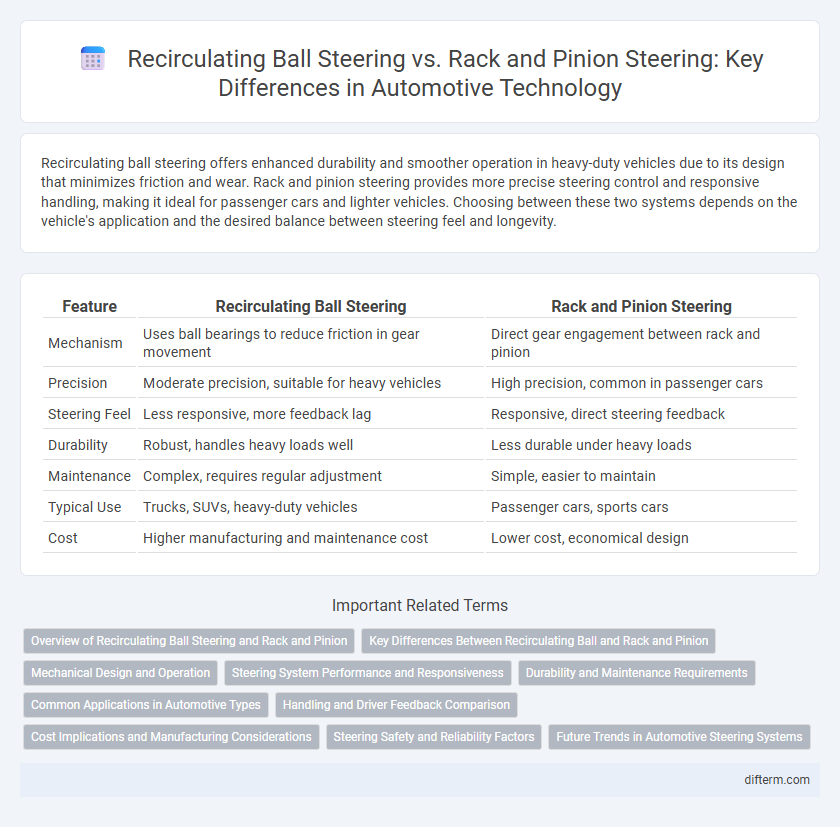

Recirculating ball steering offers enhanced durability and smoother operation in heavy-duty vehicles due to its design that minimizes friction and wear. Rack and pinion steering provides more precise steering control and responsive handling, making it ideal for passenger cars and lighter vehicles. Choosing between these two systems depends on the vehicle's application and the desired balance between steering feel and longevity.

Table of Comparison

| Feature | Recirculating Ball Steering | Rack and Pinion Steering |

|---|---|---|

| Mechanism | Uses ball bearings to reduce friction in gear movement | Direct gear engagement between rack and pinion |

| Precision | Moderate precision, suitable for heavy vehicles | High precision, common in passenger cars |

| Steering Feel | Less responsive, more feedback lag | Responsive, direct steering feedback |

| Durability | Robust, handles heavy loads well | Less durable under heavy loads |

| Maintenance | Complex, requires regular adjustment | Simple, easier to maintain |

| Typical Use | Trucks, SUVs, heavy-duty vehicles | Passenger cars, sports cars |

| Cost | Higher manufacturing and maintenance cost | Lower cost, economical design |

Overview of Recirculating Ball Steering and Rack and Pinion

Recirculating ball steering uses a series of ball bearings to reduce friction between the steering wheel and the steering linkage, providing durability and smoothness in heavy-duty vehicles. Rack and pinion steering employs a gearset where the rotational motion of the pinion turns the steering rack laterally, offering precise handling and responsiveness in passenger cars. The choice between these systems impacts vehicle steering feel, maintenance, and application suitability within automotive design.

Key Differences Between Recirculating Ball and Rack and Pinion

Recirculating ball steering utilizes a series of ball bearings to reduce friction between the steering gear and the worm gear, providing smoother operation and better durability, commonly found in heavy-duty trucks and older vehicles. Rack and pinion steering offers a more direct and responsive feel by converting rotational motion into linear motion through a pinion gear engaging a rack, making it the preferred choice for most modern passenger cars. The key differences include the complexity and size of the mechanism, steering precision, and vehicle application, with recirculating ball steering favoring robustness and load tolerance, while rack and pinion emphasizes simplicity, lightweight design, and enhanced road feedback.

Mechanical Design and Operation

Recirculating ball steering utilizes a system of ball bearings circulating within a worm gear to reduce friction and enhance durability, making it well-suited for heavy-duty vehicles with high steering loads. Rack and pinion steering features a direct mechanical connection where a round pinion gear meshes with a linear rack, providing precise and responsive steering ideal for passenger cars. The mechanical design of recirculating ball systems offers superior feedback dampening and longevity, whereas rack and pinion designs prioritize compactness and steering accuracy.

Steering System Performance and Responsiveness

Recirculating ball steering systems offer durability and robustness, making them suitable for heavy-duty vehicles, but they generally exhibit less precise responsiveness and slower feedback compared to rack and pinion systems. Rack and pinion steering provides improved steering system performance with a direct mechanical connection leading to quicker response times, enhanced road feel, and greater handling accuracy. The rack and pinion design is favored in passenger cars for its balance of precision and simplicity, contributing to better steering control and driver confidence.

Durability and Maintenance Requirements

Recirculating ball steering offers superior durability due to its robust design, making it ideal for heavy-duty vehicles and off-road applications where high torque and prolonged use are common. Rack and pinion steering systems demand less maintenance because of their simpler construction, but they wear out faster, especially under harsh driving conditions and high mileage. Maintenance for recirculating ball systems involves regular lubrication and checking for wear in the worm gear and ball bearings, whereas rack and pinion systems require more frequent inspections of tie rods and rack seals to prevent leaks and ensure responsiveness.

Common Applications in Automotive Types

Recirculating ball steering is commonly found in heavy-duty vehicles such as trucks, SUVs, and off-road vehicles due to its durability and ability to handle high steering loads. Rack and pinion steering dominates passenger cars and light vehicles, providing precise control and better road feedback ideal for everyday driving. The choice between these systems depends on vehicle size, weight, and intended use, with recirculating ball preferred for rugged applications and rack and pinion favored for performance and efficiency in smaller autos.

Handling and Driver Feedback Comparison

Recirculating ball steering offers smoother operation and better durability, ideal for heavy-duty vehicles but provides less precise handling and reduced driver feedback. Rack and pinion steering delivers more responsive control and sharper handling, enhancing driver feel and road feedback in passenger cars. This makes rack and pinion the preferred choice for performance-oriented driving due to its direct connection and minimal play.

Cost Implications and Manufacturing Considerations

Recirculating ball steering systems generally incur higher manufacturing costs due to their complex design and increased material requirements compared to rack and pinion systems. Rack and pinion steering offers cost efficiency with simpler assembly processes and fewer components, making it favored for mass production in passenger vehicles. The choice between these steering types significantly impacts overall vehicle production budgets and influences long-term maintenance expenses.

Steering Safety and Reliability Factors

Recirculating ball steering systems offer enhanced durability and are often favored in heavy-duty vehicles due to their robust construction and ability to handle higher torque loads, increasing overall safety and reliability. Rack and pinion steering provides more precise control and quicker response times, which improves maneuverability and reduces driver fatigue, contributing to safer vehicle operation. Both systems require regular maintenance to ensure optimal performance, but rack and pinion steering's simpler design often leads to fewer failure points and improved long-term reliability in passenger vehicles.

Future Trends in Automotive Steering Systems

Future trends in automotive steering systems highlight a shift towards advanced rack and pinion designs integrated with electronic power steering (EPS) for improved precision and efficiency. Innovations include steer-by-wire technology eliminating mechanical linkages, enabling faster response and adaptive feedback tailored to driving conditions. Autonomous vehicles rely heavily on these electronically controlled systems to enhance safety, reduce maintenance, and support seamless integration with driver-assistance technologies.

recirculating ball steering vs rack and pinion steering Infographic

difterm.com

difterm.com