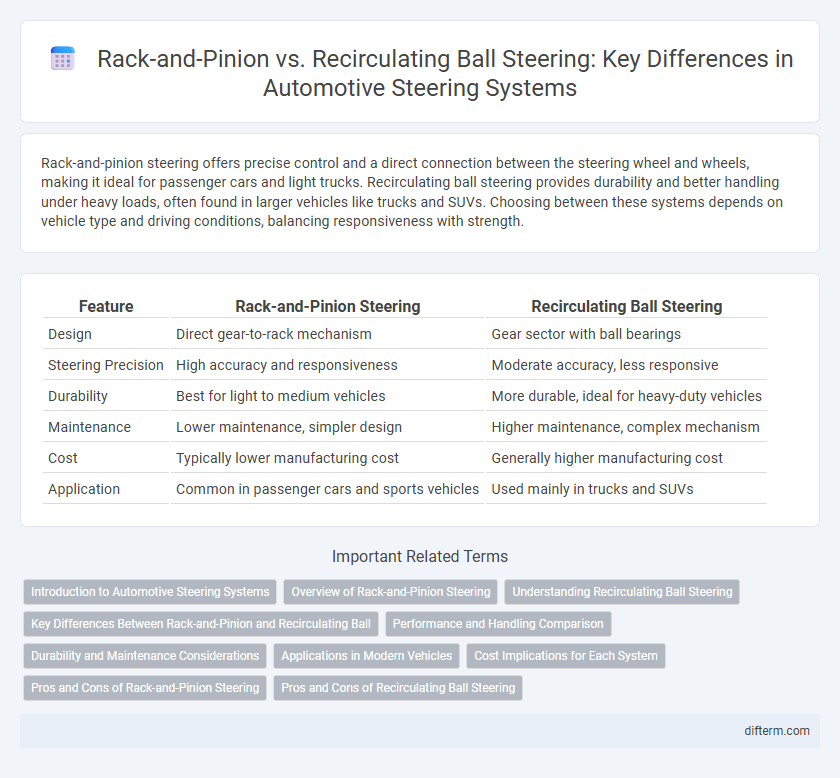

Rack-and-pinion steering offers precise control and a direct connection between the steering wheel and wheels, making it ideal for passenger cars and light trucks. Recirculating ball steering provides durability and better handling under heavy loads, often found in larger vehicles like trucks and SUVs. Choosing between these systems depends on vehicle type and driving conditions, balancing responsiveness with strength.

Table of Comparison

| Feature | Rack-and-Pinion Steering | Recirculating Ball Steering |

|---|---|---|

| Design | Direct gear-to-rack mechanism | Gear sector with ball bearings |

| Steering Precision | High accuracy and responsiveness | Moderate accuracy, less responsive |

| Durability | Best for light to medium vehicles | More durable, ideal for heavy-duty vehicles |

| Maintenance | Lower maintenance, simpler design | Higher maintenance, complex mechanism |

| Cost | Typically lower manufacturing cost | Generally higher manufacturing cost |

| Application | Common in passenger cars and sports vehicles | Used mainly in trucks and SUVs |

Introduction to Automotive Steering Systems

Rack-and-pinion steering systems use a gearset that converts the rotational motion of the steering wheel directly into linear motion, providing precise and responsive control ideal for modern passenger vehicles. Recirculating ball steering features a worm gear mechanism with ball bearings to reduce friction, commonly found in heavy-duty trucks and older vehicles due to its durability and ability to handle higher loads. Both steering types serve critical roles in automotive design, with rack-and-pinion favored for accuracy and lightweight construction, while recirculating ball excels in strength and longevity under demanding driving conditions.

Overview of Rack-and-Pinion Steering

Rack-and-pinion steering offers precise control by converting the rotational motion of the steering wheel into linear motion, directly turning the vehicle's wheels. This system consists of a gearset composed of a circular gear (the pinion) engaging a linear gear (the rack), providing responsive handling and steering feedback. Commonly found in modern passenger cars, rack-and-pinion steering delivers improved maneuverability and simplicity compared to recirculating ball steering systems.

Understanding Recirculating Ball Steering

Recirculating ball steering systems utilize a series of ball bearings that reduce friction and wear between the steering gear and the worm gear, enhancing durability in heavy-duty vehicles. This mechanism provides a smoother, more controlled steering experience in trucks and off-road vehicles compared to rack-and-pinion systems, which are typically found in passenger cars. The design's ability to handle higher torque loads makes recirculating ball steering ideal for applications requiring robust performance and longevity.

Key Differences Between Rack-and-Pinion and Recirculating Ball

Rack-and-pinion steering provides more precise handling and direct feedback, ideal for passenger cars and light vehicles, while recirculating ball steering offers greater durability and smoother operation, commonly found in trucks and heavy-duty vehicles. Rack-and-pinion systems use a simple gear and rack mechanism for quick response, whereas recirculating ball systems employ ball bearings to reduce friction and enhance torque transfer. The compact size of rack-and-pinion mechanisms favors space efficiency, contrasting with the larger, more complex design of recirculating ball steering assemblies.

Performance and Handling Comparison

Rack-and-pinion steering offers more precise and responsive handling due to its direct mechanical connection, enhancing vehicle performance during sharp turns and high-speed maneuvers. Recirculating ball steering provides smoother operation and greater durability, especially in heavy-duty or off-road vehicles, but tends to deliver less tactile feedback and slower response times. For sports cars and performance vehicles, rack-and-pinion systems optimize steering accuracy, while recirculating ball systems prioritize robustness over precision.

Durability and Maintenance Considerations

Rack-and-pinion steering systems offer higher precision but generally experience faster wear due to their simpler design, requiring more frequent maintenance such as lubrication and component replacement. Recirculating ball steering mechanisms provide enhanced durability with robust construction, suitable for heavy-duty vehicles, and often demand less frequent maintenance though repairs tend to be more complex. Choosing between these depends on application-specific factors like vehicle load, usage intensity, and maintenance preferences, with rack-and-pinion favoring lighter vehicles and recirculating ball excelling in rugged conditions.

Applications in Modern Vehicles

Rack-and-pinion steering is predominantly utilized in modern passenger cars due to its precise control and compact design, enhancing responsiveness and fuel efficiency. Recirculating ball steering, favored in heavier vehicles like trucks and SUVs, offers greater durability and better handling under high load conditions. The choice between these systems depends heavily on vehicle size, weight, and intended use, with rack-and-pinion dominating urban and light-duty applications and recirculating ball steering preferred for rugged, off-road, and commercial vehicles.

Cost Implications for Each System

Rack-and-pinion steering systems generally offer lower manufacturing and maintenance costs due to their simpler design and fewer components, making them a cost-effective choice for modern passenger vehicles. Recirculating ball steering systems, while more robust and suitable for heavy-duty applications, incur higher costs because of their complex mechanism and increased need for regular maintenance and repair. The choice between these systems often balances initial investment against long-term durability and operational expenses.

Pros and Cons of Rack-and-Pinion Steering

Rack-and-pinion steering offers precise and responsive handling, making it ideal for passenger vehicles and sports cars due to its direct connection between the steering wheel and wheels. It features a simpler design with fewer moving parts, resulting in lower maintenance costs and improved reliability compared to recirculating ball systems. However, rack-and-pinion systems can be more susceptible to wear on rack teeth and may not handle heavy-duty applications or off-road conditions as effectively as recirculating ball steering.

Pros and Cons of Recirculating Ball Steering

Recirculating ball steering offers improved durability and reduced steering effort, making it ideal for heavy-duty vehicles and trucks. Its design minimizes friction and wear by using ball bearings to recirculate, providing a smoother steering feel under heavy loads. However, it tends to be less precise and heavier compared to rack-and-pinion systems, resulting in reduced steering responsiveness and increased weight.

rack-and-pinion vs recirculating ball steering Infographic

difterm.com

difterm.com