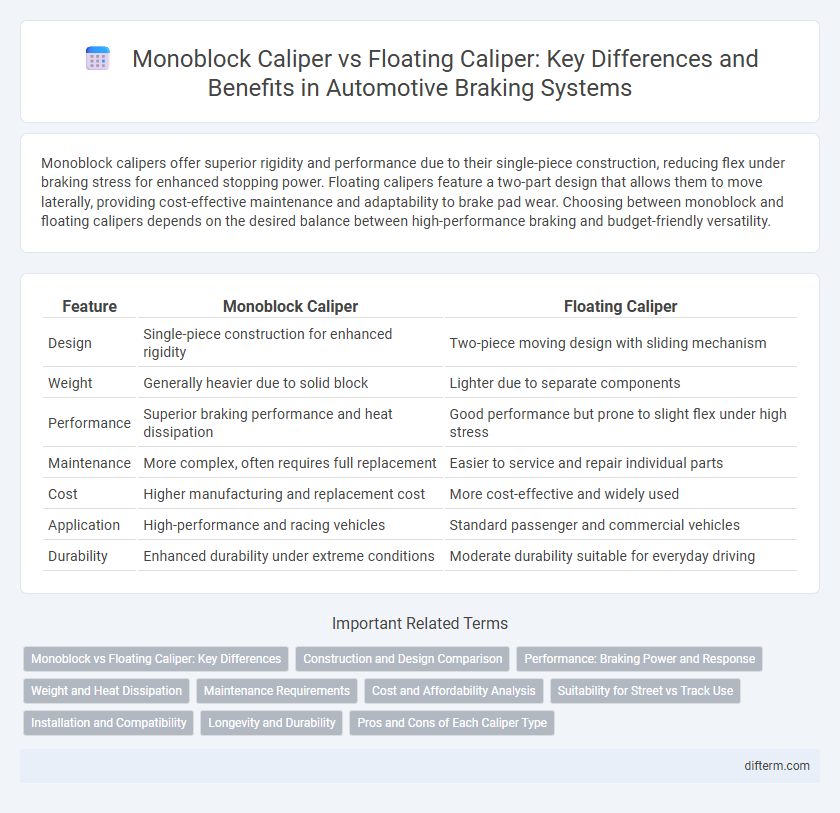

Monoblock calipers offer superior rigidity and performance due to their single-piece construction, reducing flex under braking stress for enhanced stopping power. Floating calipers feature a two-part design that allows them to move laterally, providing cost-effective maintenance and adaptability to brake pad wear. Choosing between monoblock and floating calipers depends on the desired balance between high-performance braking and budget-friendly versatility.

Table of Comparison

| Feature | Monoblock Caliper | Floating Caliper |

|---|---|---|

| Design | Single-piece construction for enhanced rigidity | Two-piece moving design with sliding mechanism |

| Weight | Generally heavier due to solid block | Lighter due to separate components |

| Performance | Superior braking performance and heat dissipation | Good performance but prone to slight flex under high stress |

| Maintenance | More complex, often requires full replacement | Easier to service and repair individual parts |

| Cost | Higher manufacturing and replacement cost | More cost-effective and widely used |

| Application | High-performance and racing vehicles | Standard passenger and commercial vehicles |

| Durability | Enhanced durability under extreme conditions | Moderate durability suitable for everyday driving |

Monoblock vs Floating Caliper: Key Differences

Monoblock calipers are machined from a single piece of metal, providing superior rigidity and improved braking performance due to reduced flex under high pressure. Floating calipers consist of separate components that slide or float on pins, offering a lighter design and cost efficiency but potentially less precise braking response. The key differences lie in construction material, weight, braking efficiency, and maintenance complexity, with monoblock calipers preferred in high-performance vehicles and floating calipers commonly used in everyday passenger cars.

Construction and Design Comparison

Monoblock calipers are crafted from a single solid piece of metal, enhancing rigidity and reducing flex during braking, which improves stopping power and pedal feel. Floating calipers consist of a fixed bracket and a sliding caliper that moves laterally, allowing for simpler, lighter construction but potentially less braking precision. The monoblock design typically supports higher-performance applications due to its robust construction, while floating calipers are more common in everyday vehicles because of their cost-effectiveness and ease of manufacturing.

Performance: Braking Power and Response

Monoblock calipers, forged from a single piece of aluminum alloy, deliver superior braking power and enhanced response due to increased rigidity and reduced flex compared to floating calipers. Floating calipers, featuring a sliding mechanism, offer reliable performance but may experience slight flex under high stress, leading to less precise brake modulation. High-performance vehicles benefit from monoblock calipers' ability to maintain consistent pressure and heat dissipation, optimizing stopping power in demanding conditions.

Weight and Heat Dissipation

Monoblock calipers, crafted from a single solid piece of aluminum, offer superior weight reduction compared to floating calipers, which use separate components and typically weigh more due to their complex design. The solid structure of monoblock calipers enhances heat dissipation efficiency by minimizing thermal expansion and promoting uniform heat distribution, critical for high-performance braking systems. Floating calipers, while generally heavier, may experience uneven heat dissipation which can lead to increased brake fade under extreme conditions.

Maintenance Requirements

Monoblock calipers generally require less maintenance due to their single-piece construction, which reduces the risk of leaks and misalignment. Floating calipers, with their movable components, demand more frequent inspection and lubrication to prevent uneven pad wear and ensure proper operation. Selecting the appropriate caliper type impacts long-term brake system reliability and maintenance costs.

Cost and Affordability Analysis

Monoblock calipers generally offer higher manufacturing costs due to their single-piece design, requiring more precise machining and premium materials, which increases the initial investment for automotive manufacturers. Floating calipers, being composed of multiple parts, are more cost-effective to produce and easier to repair, making them a preferred choice in budget-friendly vehicle models. The affordability analysis favors floating calipers for mass-market applications, while monoblock calipers justify their higher cost through enhanced performance and durability in premium or high-performance automotive segments.

Suitability for Street vs Track Use

Monoblock calipers offer superior rigidity and heat dissipation, making them ideal for high-performance track use where consistent braking and reduced flex are critical. Floating calipers provide sufficient stopping power with lighter weight and lower cost, making them more suitable for everyday street driving and moderate braking demands. Choosing between the two depends on prioritizing track-level performance or street-oriented practicality.

Installation and Compatibility

Monoblock calipers require precise mounting points and are often compatible with high-performance brake rotors due to their rigid single-piece design, ensuring a secure fit. Floating calipers offer greater flexibility in installation across various vehicle models, as their sliding mechanism accommodates slight misalignments and different rotor sizes. Compatibility considerations prioritize monoblock calipers for sports cars with aftermarket brakes, while floating calipers suit standard road vehicles for easier replacement and maintenance.

Longevity and Durability

Monoblock calipers, crafted from a single piece of aluminum or steel, offer superior rigidity and reduced flex, resulting in enhanced longevity and durability under high-stress braking conditions. Floating calipers, with their sliding mechanism and multiple components, may experience more wear and require frequent maintenance due to potential caliper movement and uneven pad wear. High-performance vehicles often favor monoblock calipers for consistent braking performance and extended service life in demanding environments.

Pros and Cons of Each Caliper Type

Monoblock calipers offer superior rigidity and better braking performance due to their single-piece construction, reducing flex under heavy braking but tend to be heavier and more expensive. Floating calipers are lighter and more cost-effective, allowing easier maintenance and replacement, though they can exhibit slight flex and reduced precision under extreme braking conditions. Choosing between monoblock and floating calipers depends on balancing performance needs, weight considerations, and budget constraints in automotive braking systems.

monoblock caliper vs floating caliper Infographic

difterm.com

difterm.com