Unibody construction integrates the vehicle's frame and body into a single cohesive unit, providing enhanced rigidity and lighter weight for improved fuel efficiency and handling. Body-on-frame design features a separate frame supporting the drivetrain and suspension, offering superior durability and easier repairs, ideal for heavy-duty and off-road applications. Choosing between unibody and body-on-frame depends on the automotive pet's intended use, balancing comfort and performance against strength and utility.

Table of Comparison

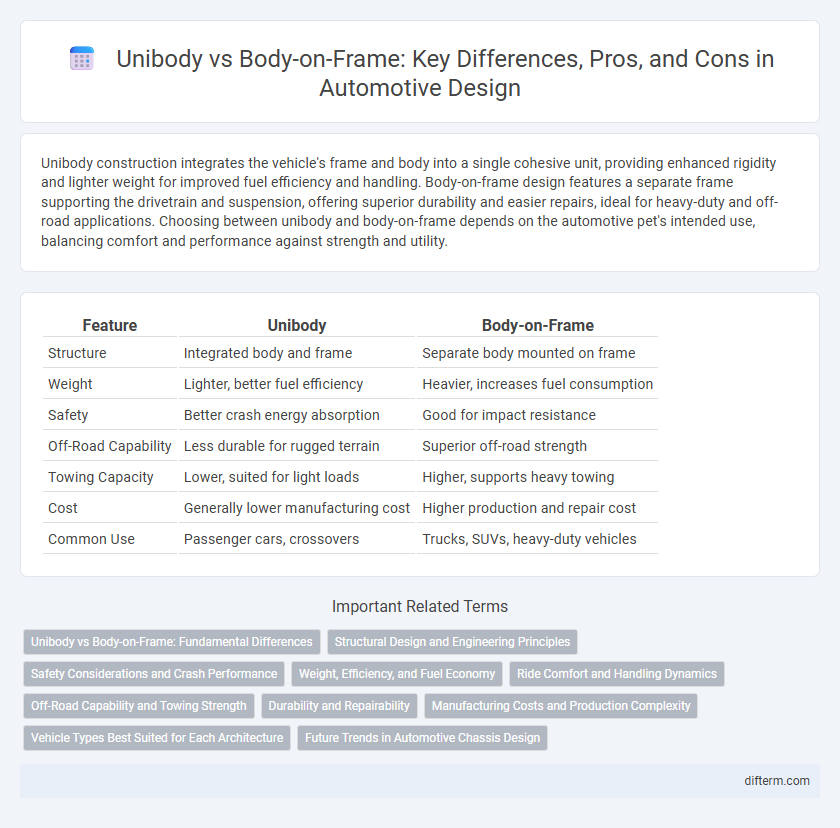

| Feature | Unibody | Body-on-Frame |

|---|---|---|

| Structure | Integrated body and frame | Separate body mounted on frame |

| Weight | Lighter, better fuel efficiency | Heavier, increases fuel consumption |

| Safety | Better crash energy absorption | Good for impact resistance |

| Off-Road Capability | Less durable for rugged terrain | Superior off-road strength |

| Towing Capacity | Lower, suited for light loads | Higher, supports heavy towing |

| Cost | Generally lower manufacturing cost | Higher production and repair cost |

| Common Use | Passenger cars, crossovers | Trucks, SUVs, heavy-duty vehicles |

Unibody vs Body-on-Frame: Fundamental Differences

Unibody construction integrates the vehicle's body and frame into a single cohesive structure, enhancing rigidity, reducing weight, and improving fuel efficiency, making it ideal for passenger cars and crossovers. Body-on-frame design separates the body from the frame, providing superior durability and off-road capability, which is favored in trucks and large SUVs for heavy towing and rugged terrain. Understanding these fundamental differences helps consumers choose based on performance needs, safety, and driving conditions.

Structural Design and Engineering Principles

Unibody construction integrates the vehicle's body and frame into a single, rigid structure, enhancing overall torsional stiffness and crash energy absorption. Body-on-frame design separates the frame and body, allowing for easier repairs and better load distribution in heavy-duty applications. Engineering principles emphasize unibody for improved fuel efficiency and handling, while body-on-frame caters to durability and off-road capability.

Safety Considerations and Crash Performance

Unibody construction enhances safety by integrating the vehicle's body and frame into a single strong structure, improving crash energy absorption and reducing cabin intrusion during collisions. Body-on-frame designs offer superior durability and better performance in off-road crashes but tend to transfer more impact forces to occupants due to the separate frame and body components. Advances in unibody engineering, such as crumple zones and high-strength steel, have significantly improved crash performance and occupant protection compared to traditional body-on-frame vehicles.

Weight, Efficiency, and Fuel Economy

Unibody construction integrates the vehicle's frame and body into a single, lightweight structure, significantly reducing overall weight compared to the heavier body-on-frame design. This weight reduction enhances fuel efficiency by lowering the energy required for acceleration and improving aerodynamics. In contrast, body-on-frame vehicles, typically used in trucks and SUVs for durability and off-road capability, tend to sacrifice fuel economy due to increased mass and structural rigidity.

Ride Comfort and Handling Dynamics

Unibody construction enhances ride comfort and handling dynamics by integrating the body and frame into a single structure, reducing vehicle weight and increasing rigidity for better road responsiveness. Body-on-frame designs typically result in a rougher ride due to higher weight and less structural stiffness, but excel in off-road durability and towing capacity. For passenger cars and crossover SUVs, unibody offers superior handling precision and smoother driving experience, while body-on-frame remains preferred in heavy-duty trucks and large SUVs prioritizing ruggedness.

Off-Road Capability and Towing Strength

Unibody construction offers lighter weight and improved handling, making it suitable for moderate off-road use but generally has lower towing capacity compared to body-on-frame designs. Body-on-frame vehicles provide superior durability and structural integrity, enhancing off-road capability and enabling higher towing strength, often exceeding 10,000 pounds. Heavy-duty trucks and rugged SUVs typically use body-on-frame architecture to withstand harsh terrain and heavy loads.

Durability and Repairability

Unibody construction offers enhanced durability by integrating the frame and body into a single cohesive structure, reducing flex and improving crash impact absorption. Body-on-frame designs provide superior repairability since damaged body panels can be replaced independently without affecting the underlying frame. Off-road and heavy-duty vehicles often favor body-on-frame for its robustness and ease of frame repairs after terrain-induced stress.

Manufacturing Costs and Production Complexity

Unibody construction integrates the vehicle's body and frame into a single structure, significantly reducing manufacturing costs by streamlining assembly processes and requiring fewer materials. Body-on-frame designs involve separate chassis and body components, increasing production complexity due to additional welding, bolting, and alignment steps, which drives up labor and tooling expenses. The unibody approach benefits mass production with greater efficiency, while body-on-frame remains costlier but offers enhanced durability for heavy-duty applications.

Vehicle Types Best Suited for Each Architecture

Unibody construction is best suited for passenger cars, crossovers, and SUVs prioritizing fuel efficiency, handling, and ride comfort due to its integrated frame and body design that reduces weight and enhances rigidity. Body-on-frame architecture excels in trucks, large SUVs, and off-road vehicles requiring superior durability, towing capacity, and ease of repair since the frame supports heavy loads and absorbs impacts independently. Sports cars and most sedans typically adopt unibody structures, while heavy-duty pickups and commercial vehicles rely on body-on-frame layouts for rugged performance and versatility.

Future Trends in Automotive Chassis Design

Future trends in automotive chassis design emphasize the shift from traditional body-on-frame to advanced unibody constructions that enhance vehicle rigidity and reduce weight, leading to improved fuel efficiency and safety. Innovations in high-strength steel and aluminum alloys enable unibody chassis to withstand greater stresses, supporting electric and autonomous vehicle architectures. Integration of smart materials and modular design in unibody systems promises quicker manufacturing and easier repairs, driving the evolution of automotive structural engineering.

unibody vs body-on-frame Infographic

difterm.com

difterm.com