CAN bus offers high-speed communication with robust error handling, making it ideal for complex automotive systems requiring real-time data exchange. LIN bus is a cost-effective, slower alternative suited for simple control tasks like window and mirror adjustments. Choosing between CAN and LIN depends on system complexity, speed requirements, and budget constraints in automotive electronic design.

Table of Comparison

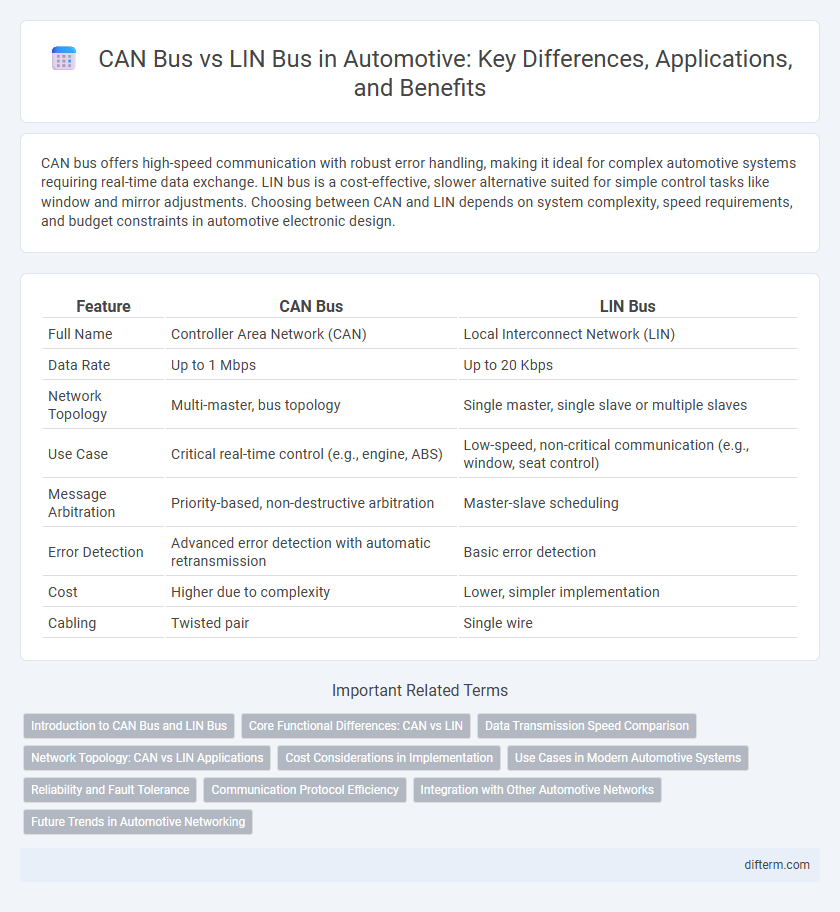

| Feature | CAN Bus | LIN Bus |

|---|---|---|

| Full Name | Controller Area Network (CAN) | Local Interconnect Network (LIN) |

| Data Rate | Up to 1 Mbps | Up to 20 Kbps |

| Network Topology | Multi-master, bus topology | Single master, single slave or multiple slaves |

| Use Case | Critical real-time control (e.g., engine, ABS) | Low-speed, non-critical communication (e.g., window, seat control) |

| Message Arbitration | Priority-based, non-destructive arbitration | Master-slave scheduling |

| Error Detection | Advanced error detection with automatic retransmission | Basic error detection |

| Cost | Higher due to complexity | Lower, simpler implementation |

| Cabling | Twisted pair | Single wire |

Introduction to CAN Bus and LIN Bus

The Controller Area Network (CAN) bus enables robust, high-speed communication between microcontrollers and devices within automotive systems, supporting real-time control and diagnostics. The Local Interconnect Network (LIN) bus complements CAN by offering a cost-effective, lower-speed communication protocol ideal for non-critical subsystems such as window regulators and seat controllers. Both buses enhance vehicle network efficiency by addressing different speed and complexity requirements in modern automotive architectures.

Core Functional Differences: CAN vs LIN

CAN bus supports high-speed, real-time communication with multi-master capabilities and error detection, ideal for critical automotive systems like engine control and ABS. LIN bus operates at lower speeds with a single-master, multiple-slave configuration, suited for simple, cost-effective subsystems such as window controls and seat adjustments. The core functional difference lies in CAN's robust, fault-tolerant data exchange versus LIN's simplified, slower communication protocol.

Data Transmission Speed Comparison

CAN bus supports data transmission speeds of up to 1 Mbps, making it suitable for time-critical automotive applications such as engine control and real-time diagnostics. LIN bus operates at a maximum speed of 20 Kbps, designed primarily for simpler, low-speed communication tasks like window control and seat adjustment. The significant speed disparity reflects CAN bus's role in high-speed, robust data exchange versus LIN bus's function in cost-effective, lower-speed networks.

Network Topology: CAN vs LIN Applications

CAN bus employs a multi-master, differential signaling network topology ideal for high-speed, critical automotive applications like engine control units and safety systems. LIN bus uses a single-master, single-slave serial network topology suited for lower-speed, cost-sensitive applications such as window controls, seat adjustment, and interior lighting. The robust, collision-resistant design of CAN supports complex communication across numerous ECUs, while LIN offers simplified, linear network architecture for less complex, localized control functions.

Cost Considerations in Implementation

CAN bus generally incurs higher implementation costs due to its complex hardware and robust protocol requirements, making it suitable for high-speed, critical automotive systems. LIN bus offers a cost-effective alternative with simpler wiring and lower data rates, ideal for body electronics and less demanding applications. Choosing between CAN and LIN depends on balancing budget constraints against system performance and reliability needs.

Use Cases in Modern Automotive Systems

CAN bus excels in high-speed data communication for critical automotive systems such as engine management, ABS, and airbag deployment, ensuring real-time performance and reliability. LIN bus is optimized for lower-speed applications like window controls, seat adjustments, and climate control, providing a cost-effective and simpler solution for body electronics. Modern vehicles integrate both buses, leveraging CAN for complex safety and powertrain functions while employing LIN for auxiliary subsystems to optimize network efficiency and reduce wiring complexity.

Reliability and Fault Tolerance

CAN bus offers higher reliability and fault tolerance compared to LIN bus due to its robust error detection mechanisms, such as CRC checks and automatic retransmission. The CAN protocol supports multi-master communication and fault confinement, allowing the network to isolate faulty nodes without disrupting overall functionality. In contrast, LIN bus, designed for simpler sub-systems, has limited fault management capabilities and relies on a single master controller, making it less resilient in critical automotive applications.

Communication Protocol Efficiency

CAN bus offers higher communication protocol efficiency with faster data rates up to 1 Mbps and robust error detection, making it ideal for time-critical automotive systems. LIN bus operates at lower speeds, typically up to 20 Kbps, and uses simpler protocols designed for less critical, cost-sensitive applications such as body electronics. The efficiency of CAN bus supports real-time control and diagnostics, while LIN bus provides a streamlined solution for auxiliary device coordination with reduced wiring complexity.

Integration with Other Automotive Networks

CAN bus offers high-speed data transfer and robust error handling, making it ideal for integrating critical automotive systems such as engine control units (ECUs) and safety modules with other networks like Ethernet or FlexRay. LIN bus operates at lower speeds and is optimized for simple, cost-effective communication in body electronics, seamlessly connecting components like door modules, climate control, and sensors to CAN bus gateways. Effective integration between CAN and LIN buses enhances overall vehicle network efficiency by enabling hierarchical communication architecture and centralized diagnostics.

Future Trends in Automotive Networking

CAN bus and LIN bus technologies are evolving to meet the demands of increasingly complex automotive networking systems, with CAN FD (Flexible Data-rate) enhancing data throughput and LIN adopting LIN 2.2 for improved diagnostics and faster communication. Future trends emphasize integration with Ethernet-based solutions to support high-bandwidth applications such as advanced driver-assistance systems (ADAS) and autonomous driving. The convergence of CAN, LIN, and automotive Ethernet enables scalable, reliable, and secure in-vehicle networks that drive innovation in connected and electric vehicles.

CAN bus vs LIN bus Infographic

difterm.com

difterm.com