Coil springs offer superior ride comfort and better handling due to their ability to absorb shocks more effectively, making them ideal for passenger vehicles. Leaf springs provide greater load-carrying capacity and durability, which is why they are commonly used in trucks and heavy-duty vehicles. Choosing between coil springs and leaf springs depends on the vehicle's purpose, balancing comfort with strength requirements.

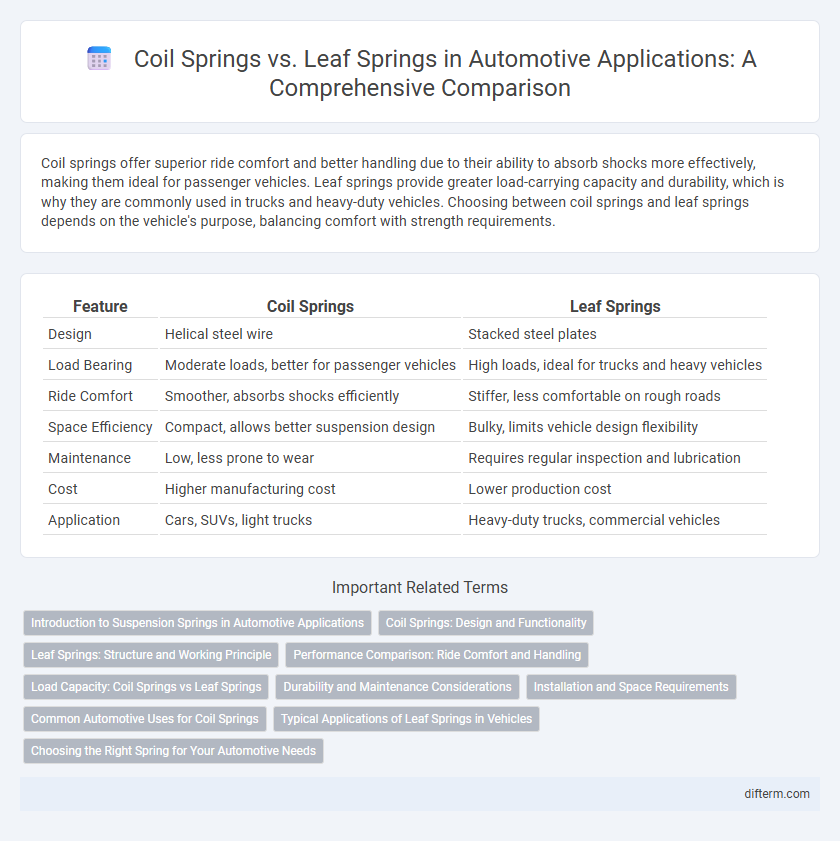

Table of Comparison

| Feature | Coil Springs | Leaf Springs |

|---|---|---|

| Design | Helical steel wire | Stacked steel plates |

| Load Bearing | Moderate loads, better for passenger vehicles | High loads, ideal for trucks and heavy vehicles |

| Ride Comfort | Smoother, absorbs shocks efficiently | Stiffer, less comfortable on rough roads |

| Space Efficiency | Compact, allows better suspension design | Bulky, limits vehicle design flexibility |

| Maintenance | Low, less prone to wear | Requires regular inspection and lubrication |

| Cost | Higher manufacturing cost | Lower production cost |

| Application | Cars, SUVs, light trucks | Heavy-duty trucks, commercial vehicles |

Introduction to Suspension Springs in Automotive Applications

Coil springs provide consistent performance and better shock absorption, making them ideal for passenger vehicles requiring smooth rides. Leaf springs offer robust load-bearing capacity and durability, commonly used in trucks and heavy-duty vehicles to support heavy weights. Understanding the differences in suspension spring mechanics is crucial for optimizing vehicle handling and comfort in diverse automotive applications.

Coil Springs: Design and Functionality

Coil springs in automotive suspension systems provide superior ride comfort and precise handling by compressing and absorbing shocks through tightly wound helical steel. Their compact design allows for easy integration into independent suspension setups, enhancing wheel articulation and vehicle stability. Compared to leaf springs, coil springs deliver more consistent performance under varied load conditions and reduce unsprung weight, improving overall driving dynamics.

Leaf Springs: Structure and Working Principle

Leaf springs consist of multiple layers of curved steel strips stacked and clamped together, providing durability and load-bearing capacity ideal for heavy-duty vehicles. Their working principle relies on the flexing of the spring leaves under load, which absorbs shocks and distributes weight evenly across the axle. This design offers superior stability and strength, making leaf springs effective for trucks, SUVs, and commercial vehicles.

Performance Comparison: Ride Comfort and Handling

Coil springs provide superior ride comfort by offering more consistent damping and better absorption of road irregularities, which enhances overall handling precision. Leaf springs, while durable and capable of supporting heavy loads, tend to produce a stiffer ride with less responsiveness in cornering situations. The choice between coil and leaf springs significantly influences suspension performance, affecting vehicular stability and driver control based on terrain and load demands.

Load Capacity: Coil Springs vs Leaf Springs

Coil springs generally offer lower load capacity compared to leaf springs, making them ideal for lighter vehicles and smoother rides. Leaf springs provide superior load-bearing capabilities, commonly used in trucks and heavy-duty vehicles to support substantial weight and maintain stability. The design of leaf springs distributes weight more evenly, enhancing durability under heavy loads.

Durability and Maintenance Considerations

Coil springs offer superior durability over leaf springs due to their resistance to fatigue and ability to maintain consistent performance under various loads. Maintenance of coil springs is generally minimal, requiring less frequent inspections and replacements compared to leaf springs, which can suffer from corrosion and metal fatigue. Leaf springs, while robust for heavy-duty applications, often demand regular lubrication and are more prone to wear, increasing overall maintenance costs.

Installation and Space Requirements

Coil springs require less installation space due to their compact, cylindrical design, making them ideal for modern suspension systems with limited room. Leaf springs, often mounted longitudinally along the vehicle's chassis, demand more space and are typically used in heavy-duty trucks and commercial vehicles where robustness is prioritized. Installation of coil springs is generally easier on independent suspension setups, whereas leaf springs involve more complex mounting brackets and shackle assemblies.

Common Automotive Uses for Coil Springs

Coil springs are commonly used in passenger vehicles and light trucks for suspension systems due to their ability to provide a smoother ride and better handling by absorbing road shocks effectively. They are frequently found in independent suspension setups, such as MacPherson strut and multi-link systems, improving stability and comfort. Their compact design allows for more precise tuning of suspension characteristics, making them ideal for modern automotive engineering.

Typical Applications of Leaf Springs in Vehicles

Leaf springs are commonly used in heavy-duty trucks, commercial vehicles, and SUVs due to their ability to support substantial loads and provide durability under rough terrain conditions. They excel in applications requiring superior weight distribution, such as in rear suspensions of pickup trucks and large vans, helping maintain vehicle stability and load-carrying capacity. The simple design and robustness make leaf springs a preferred suspension choice for off-road vehicles and vehicles designed for heavy hauling.

Choosing the Right Spring for Your Automotive Needs

Coil springs offer superior ride comfort and precise handling, making them ideal for passenger cars and performance vehicles. Leaf springs provide exceptional load-bearing capacity and durability, commonly used in trucks and heavy-duty applications. Selecting the right spring depends on vehicle type, load requirements, and desired ride quality for optimal automotive performance.

coil springs vs leaf springs Infographic

difterm.com

difterm.com