The Boxster engine offers a compact, mid-engine layout that optimizes weight distribution and handling performance, ideal for sports cars requiring agility and balance. Inline engines provide a simpler, often more fuel-efficient design with fewer components, making them reliable and easier to maintain. Comparing both, the Boxster's engine excels in delivering high-performance driving dynamics, while inline engines prioritize efficiency and straightforward engineering.

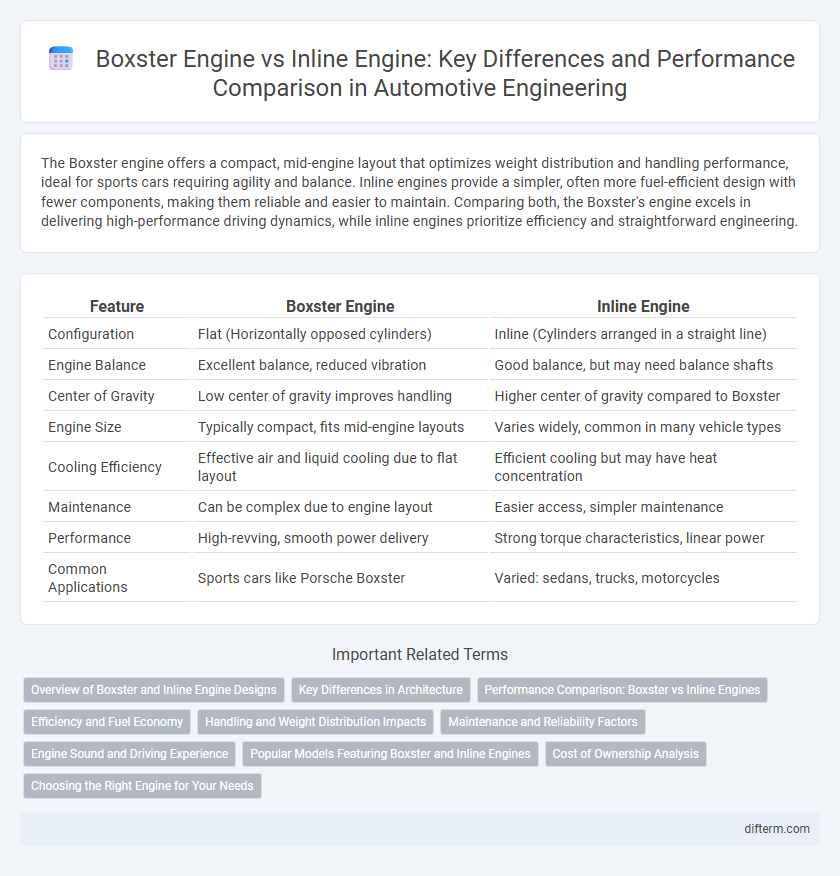

Table of Comparison

| Feature | Boxster Engine | Inline Engine |

|---|---|---|

| Configuration | Flat (Horizontally opposed cylinders) | Inline (Cylinders arranged in a straight line) |

| Engine Balance | Excellent balance, reduced vibration | Good balance, but may need balance shafts |

| Center of Gravity | Low center of gravity improves handling | Higher center of gravity compared to Boxster |

| Engine Size | Typically compact, fits mid-engine layouts | Varies widely, common in many vehicle types |

| Cooling Efficiency | Effective air and liquid cooling due to flat layout | Efficient cooling but may have heat concentration |

| Maintenance | Can be complex due to engine layout | Easier access, simpler maintenance |

| Performance | High-revving, smooth power delivery | Strong torque characteristics, linear power |

| Common Applications | Sports cars like Porsche Boxster | Varied: sedans, trucks, motorcycles |

Overview of Boxster and Inline Engine Designs

The Boxster engine features a flat, horizontally-opposed layout that lowers the vehicle's center of gravity, enhancing stability and handling in sports cars. Inline engines, characterized by cylinders arranged in a straight line, offer a simpler design with efficiency in manufacturing and smooth power delivery, commonly used in compact and mid-size vehicles. Differences in engine configuration directly impact performance dynamics, weight distribution, and packaging within the automotive design.

Key Differences in Architecture

The Boxster engine features a horizontally opposed flat-six architecture, which provides a lower center of gravity and enhances vehicle stability and handling. Inline engines utilize a straight configuration where cylinders are arranged in a single row, typically offering simpler design and maintenance but a higher center of gravity. The flat layout in Boxster engines allows for better weight distribution compared to the more compact but vertically oriented inline engines common in many sports and passenger cars.

Performance Comparison: Boxster vs Inline Engines

Boxster engines deliver a mid-engine layout that offers superior weight distribution and enhanced handling compared to traditional inline engines, which usually prioritize smooth power delivery and fuel efficiency. The flat-six Boxster engine typically produces higher horsepower and torque, resulting in quicker acceleration and more dynamic driving experiences, ideal for sports cars. Inline engines, while often more compact and cost-effective, generally sacrifice peak performance benefits for reliability and ease of maintenance in everyday vehicles.

Efficiency and Fuel Economy

The Boxster engine, typically a flat-six configuration, offers a lower center of gravity contributing to better handling and balanced power delivery, which can enhance overall driving efficiency. Inline engines, commonly found in many vehicles, tend to achieve higher thermal efficiency and fuel economy due to their simpler design and reduced internal friction. When comparing fuel economy, inline engines often outperform Boxster engines, but the Boxster's engine layout provides sportier performance characteristics that can influence real-world efficiency depending on driving conditions.

Handling and Weight Distribution Impacts

The Boxster engine's mid-engine layout significantly enhances handling by centralizing mass and lowering the center of gravity, resulting in improved balance and agility during cornering. Inline engines typically occupy a front-engine placement, which shifts weight forward and can cause understeer, reducing overall handling precision. The compact and lightweight design of the Boxster's engine setup allows for better weight distribution between front and rear axles, directly contributing to superior vehicle dynamics and driving performance.

Maintenance and Reliability Factors

Boxster engines, known for their horizontally opposed design, offer lower center of gravity and balanced weight distribution, reducing wear on suspension components and enhancing overall vehicle stability. Inline engines, with a simpler single-bank cylinder layout, typically present easier access for routine maintenance tasks such as spark plug replacement and timing belt changes, lowering service costs and downtime. Reliability differences often lean toward Boxster engines' advanced engineering yielding superior heat dissipation, whereas inline engines benefit from established robustness and less complex cooling systems, influencing long-term durability under varied driving conditions.

Engine Sound and Driving Experience

The Boxster engine delivers a distinctive, flat-six boxer engine sound characterized by a deep, throaty growl that enhances the sporty driving experience. Inline engines, often found in sports cars and sedans, produce a smoother, more linear exhaust note but lack the aggressive rumble of a boxer engine. This unique acoustic signature of the Boxster engine amplifies driver engagement and adds emotional depth to every acceleration and gear shift.

Popular Models Featuring Boxster and Inline Engines

Popular automotive models featuring Boxster engines include the Porsche Boxster series, known for its flat-six boxer engine configuration delivering a low center of gravity and exceptional handling. Inline engines power iconic vehicles such as the BMW 3 Series and Toyota Corolla, praised for their smoothness, fuel efficiency, and balanced performance. Both engine types are favored in sports and everyday cars for their distinct advantages in driving dynamics and engine packaging.

Cost of Ownership Analysis

Boxster engines generally offer lower cost of ownership due to their compact design and efficient maintenance schedules, which reduce labor and parts expenses compared to traditional inline engines. Inline engines, while often more powerful, tend to incur higher costs from increased fuel consumption and complex repair procedures. Factors such as fuel efficiency, durability, and ease of service directly influence the long-term cost-effectiveness of Boxster versus inline engine configurations.

Choosing the Right Engine for Your Needs

Boxster engines, typically flat or boxer configurations, offer a lower center of gravity for improved handling and stability, ideal for sports car enthusiasts seeking agile performance. Inline engines, known for their compact design and smooth power delivery, provide a balance of efficiency and reliability preferred in everyday driving and versatile applications. Selecting between these engines depends on prioritizing driving dynamics against practicality and maintenance considerations.

Boxster engine vs Inline engine Infographic

difterm.com

difterm.com