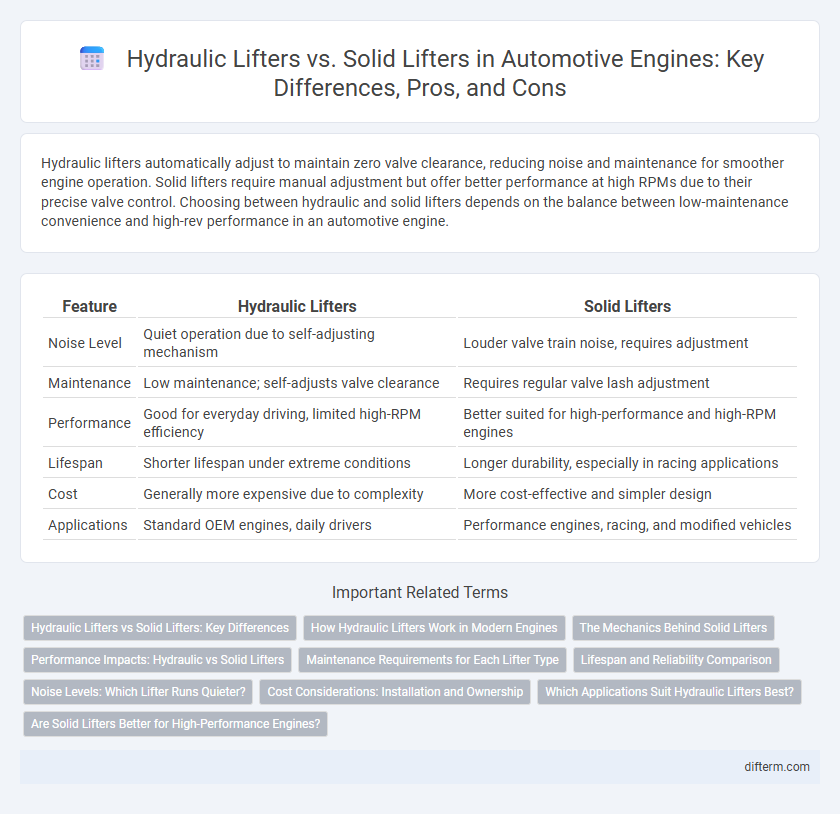

Hydraulic lifters automatically adjust to maintain zero valve clearance, reducing noise and maintenance for smoother engine operation. Solid lifters require manual adjustment but offer better performance at high RPMs due to their precise valve control. Choosing between hydraulic and solid lifters depends on the balance between low-maintenance convenience and high-rev performance in an automotive engine.

Table of Comparison

| Feature | Hydraulic Lifters | Solid Lifters |

|---|---|---|

| Noise Level | Quiet operation due to self-adjusting mechanism | Louder valve train noise, requires adjustment |

| Maintenance | Low maintenance; self-adjusts valve clearance | Requires regular valve lash adjustment |

| Performance | Good for everyday driving, limited high-RPM efficiency | Better suited for high-performance and high-RPM engines |

| Lifespan | Shorter lifespan under extreme conditions | Longer durability, especially in racing applications |

| Cost | Generally more expensive due to complexity | More cost-effective and simpler design |

| Applications | Standard OEM engines, daily drivers | Performance engines, racing, and modified vehicles |

Hydraulic Lifters vs Solid Lifters: Key Differences

Hydraulic lifters automatically adjust valve clearance using engine oil pressure, reducing maintenance and noise compared to solid lifters that require manual adjustment for optimal valve timing. Solid lifters provide more precise valve control and higher RPM potential, making them ideal for high-performance engines despite increased maintenance demands. Understanding these differences helps in selecting the appropriate lifter type based on engine performance needs and maintenance preferences.

How Hydraulic Lifters Work in Modern Engines

Hydraulic lifters in modern engines use pressurized engine oil to automatically adjust valve clearance, ensuring quieter operation and reducing the need for manual valve adjustments. The internal piston within the lifter compensates for thermal expansion and wear, maintaining optimal valve timing and performance. This self-adjusting mechanism enhances engine efficiency and longevity by maintaining consistent valve lift and timing across varying operating conditions.

The Mechanics Behind Solid Lifters

Solid lifters, also known as mechanical lifters, operate through a direct physical connection between the camshaft and the valve, ensuring precise valve timing and reduced clearance variations. Unlike hydraulic lifters, solid lifters require periodic adjustment to maintain optimal valve lash, which enhances engine performance and responsiveness under high RPM conditions. The rigid design of solid lifters allows for better control of valve movement, contributing to improved durability and efficiency in performance-oriented automotive engines.

Performance Impacts: Hydraulic vs Solid Lifters

Hydraulic lifters provide self-adjusting valve clearance, reducing maintenance and offering quieter operation, making them ideal for daily-driven engines. Solid lifters deliver precise valve timing and higher RPM capabilities, enhancing performance in high-speed and racing applications. The trade-off between durability and noise versus performance tuning is crucial when choosing between hydraulic and solid lifters for specific automotive needs.

Maintenance Requirements for Each Lifter Type

Hydraulic lifters require minimal maintenance due to their self-adjusting nature, which automatically compensates for valve clearance, reducing the need for regular adjustments. Solid lifters demand frequent inspections and periodic valve lash adjustments to maintain proper engine performance and avoid damage. Neglecting maintenance on solid lifters can lead to increased engine noise and accelerated wear on camshaft components.

Lifespan and Reliability Comparison

Hydraulic lifters offer extended lifespan and enhanced reliability due to their self-adjusting mechanism that maintains optimal valve clearance, reducing wear and minimizing maintenance needs. Solid lifters, while providing consistent performance at high RPMs, require regular adjustments and are more prone to accelerated wear if not properly maintained. Overall, hydraulic lifters deliver superior durability in daily driving conditions, whereas solid lifters are preferred in high-performance engines demanding precise valve timing.

Noise Levels: Which Lifter Runs Quieter?

Hydraulic lifters operate with self-adjusting mechanisms that maintain zero valve clearance, resulting in significantly quieter engine performance compared to solid lifters, which require manual adjustment and tend to produce more valve train noise. The use of hydraulic lifters reduces mechanical noise by automatically compensating for thermal expansion, whereas solid lifters generate more ticking sounds due to the fixed clearance. Noise levels in engines equipped with hydraulic lifters are typically lower, enhancing overall driving comfort and reducing audible wear indicators.

Cost Considerations: Installation and Ownership

Hydraulic lifters generally have a higher initial installation cost due to their complexity and precision engineering compared to solid lifters, which are simpler and less expensive to install. Over time, hydraulic lifters reduce maintenance expenses by self-adjusting valve clearance, whereas solid lifters require periodic manual adjustments, increasing labor costs during ownership. Choosing hydraulic lifters can lead to lower total cost of ownership despite the upfront investment, especially in high-mileage or performance engines.

Which Applications Suit Hydraulic Lifters Best?

Hydraulic lifters are best suited for everyday street vehicles and light-duty engines due to their self-adjusting mechanism that reduces valve train noise and maintenance. These lifters excel in applications where smooth, quiet operation and minimal valve clearance adjustments are desired, such as commuter cars and light trucks. Their ability to automatically compensate for thermal expansion makes them ideal for engines emphasizing reliability and ease of use over high-performance tuning.

Are Solid Lifters Better for High-Performance Engines?

Solid lifters offer precise valve timing and durability at high RPMs, making them ideal for high-performance engines where valve control and reliability are critical. Unlike hydraulic lifters, solid lifters require manual adjustment and maintenance but provide consistent performance without lifter pump-up or valve float. Performance engines benefit from solid lifters due to improved engine responsiveness and the ability to withstand higher valve spring pressures.

hydraulic lifters vs solid lifters Infographic

difterm.com

difterm.com