An open deck block features large gaps around the cylinder bores, providing improved coolant flow and better heat dissipation, which is ideal for high-performance engines. A closed deck block has a solid structure around the cylinders, enhancing strength and rigidity, making it suitable for heavy-duty applications and high boost pressures. Choosing between open deck and closed deck blocks depends on the balance between cooling efficiency and structural durability required for the vehicle's performance.

Table of Comparison

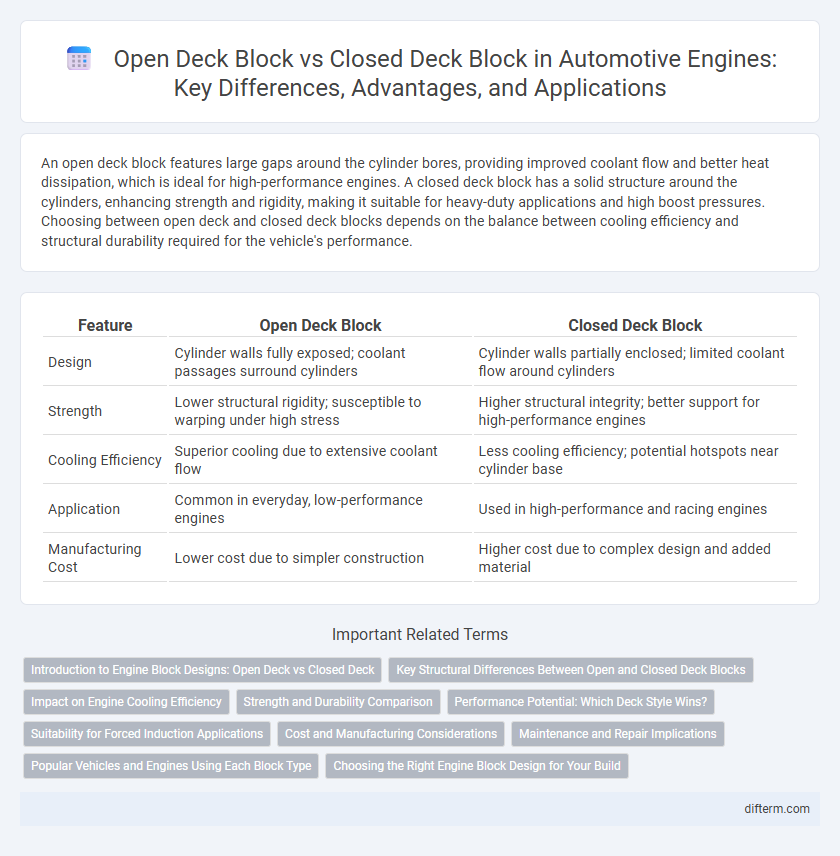

| Feature | Open Deck Block | Closed Deck Block |

|---|---|---|

| Design | Cylinder walls fully exposed; coolant passages surround cylinders | Cylinder walls partially enclosed; limited coolant flow around cylinders |

| Strength | Lower structural rigidity; susceptible to warping under high stress | Higher structural integrity; better support for high-performance engines |

| Cooling Efficiency | Superior cooling due to extensive coolant flow | Less cooling efficiency; potential hotspots near cylinder base |

| Application | Common in everyday, low-performance engines | Used in high-performance and racing engines |

| Manufacturing Cost | Lower cost due to simpler construction | Higher cost due to complex design and added material |

Introduction to Engine Block Designs: Open Deck vs Closed Deck

Open deck engine blocks feature detached cylinder walls, allowing improved cooling and easier manufacturing, ideal for everyday passenger vehicles prioritizing thermal management. Closed deck blocks provide enhanced structural rigidity by encasing the cylinder walls fully, beneficial for high-performance and heavy-duty engines requiring higher strength and reduced cylinder distortion. Understanding the trade-offs between open and closed deck designs is crucial for optimizing engine durability, cooling efficiency, and power output.

Key Structural Differences Between Open and Closed Deck Blocks

Open deck blocks feature large gaps around the cylinder bores, allowing improved coolant flow and easier maintenance, making them common in high-performance and lightweight engine designs. Closed deck blocks have reinforced material connecting the cylinder walls to the outer block, providing superior strength and rigidity essential for high-horsepower and heavy-duty applications. These structural differences affect engine durability, heat dissipation, and suitability for forced induction or high-stress environments in automotive engineering.

Impact on Engine Cooling Efficiency

Open deck blocks feature larger coolant passages surrounding the cylinders, enhancing engine cooling efficiency by allowing greater coolant flow and heat dissipation. Closed deck blocks provide increased structural rigidity but restrict coolant flow around the cylinders, potentially reducing cooling performance under high-stress conditions. Optimizing engine cooling efficiency in performance applications often involves balancing the superior flow characteristics of open deck designs with the mechanical strength benefits of closed deck configurations.

Strength and Durability Comparison

Closed deck engine blocks offer superior strength and durability due to their reinforced structure, which supports higher cylinder pressures and reduces cylinder bore distortion during high-performance applications. Open deck blocks have less material surrounding the cylinders, making them lighter but more prone to flex and overheating under extreme conditions. For high-stress environments like racing or heavy-duty use, closed deck blocks ensure enhanced longevity and reliability through increased rigidity.

Performance Potential: Which Deck Style Wins?

Closed deck blocks offer superior structural rigidity, allowing for higher cylinder pressures and improved performance potential in high-boost applications. Open deck blocks provide better cooling but sacrifice strength, limiting their capacity for extreme tuning and power output. For maximum performance gains, especially in forced induction setups, the closed deck design typically wins due to its enhanced durability and resistance to block distortion.

Suitability for Forced Induction Applications

Closed deck engine blocks offer superior strength and rigidity, making them more suitable for forced induction applications such as turbocharging or supercharging. Their design minimizes cylinder bore distortion under high boost pressures, ensuring better reliability and durability in high-performance forced induction setups. Open deck blocks, while lighter and easier to cool, often lack the structural support needed to withstand the increased stress from forced induction, limiting their use in heavily boosted engines.

Cost and Manufacturing Considerations

Open deck blocks offer lower manufacturing costs due to simpler casting processes and reduced machining complexity, making them ideal for budget-conscious automotive production. Closed deck blocks provide enhanced structural rigidity and better coolant flow control but require more intricate casting and machining, increasing overall production expenses. Automakers balance these cost differences against performance needs when selecting between open deck and closed deck engine blocks.

Maintenance and Repair Implications

Open deck engine blocks offer easier access to coolant passages, simplifying maintenance and reducing repair time due to their less complex design. Closed deck blocks provide enhanced structural rigidity, minimizing the risk of warping or cracking, which can lead to fewer long-term repairs but potentially more challenging service procedures. Choosing between the two affects overall engine durability, repair frequency, and cost-efficiency in automotive maintenance.

Popular Vehicles and Engines Using Each Block Type

Popular vehicles with open deck blocks include the Chevrolet 5.3L V8 found in Silverado pickups and the Ford 4.6L V8 powering Mustang GTs, offering easy cooling and lighter weight. Closed deck blocks are favored in performance engines like the Nissan RB26DETT in the Skyline GT-R and the Honda K20 series, providing superior strength and enhanced durability under high boost conditions. Choosing between open and closed deck designs depends on the application, with open deck common in everyday light trucks and closed deck preferred for high-performance or forced induction engines.

Choosing the Right Engine Block Design for Your Build

Open deck blocks offer superior cooling efficiency and ease of machining, making them ideal for high-performance applications with moderate boost levels. Closed deck blocks provide enhanced structural rigidity and better support for high horsepower builds, reducing cylinder wall distortion under extreme conditions. Selecting the right engine block design depends on balancing cooling needs and strength requirements based on your build's performance goals.

open deck block vs closed deck block Infographic

difterm.com

difterm.com