A splitter is designed to enhance downforce by directing airflow under the vehicle, improving stability and grip at high speeds, while an air dam primarily reduces aerodynamic drag by blocking and redirecting airflow around the front of the car. Splitters extend forward from the front bumper and work by creating a low-pressure zone underneath, whereas air dams are positioned lower to minimize air from flowing under the vehicle, reducing lift. Both components play crucial roles in automotive aerodynamics but serve distinct purposes to optimize performance and handling.

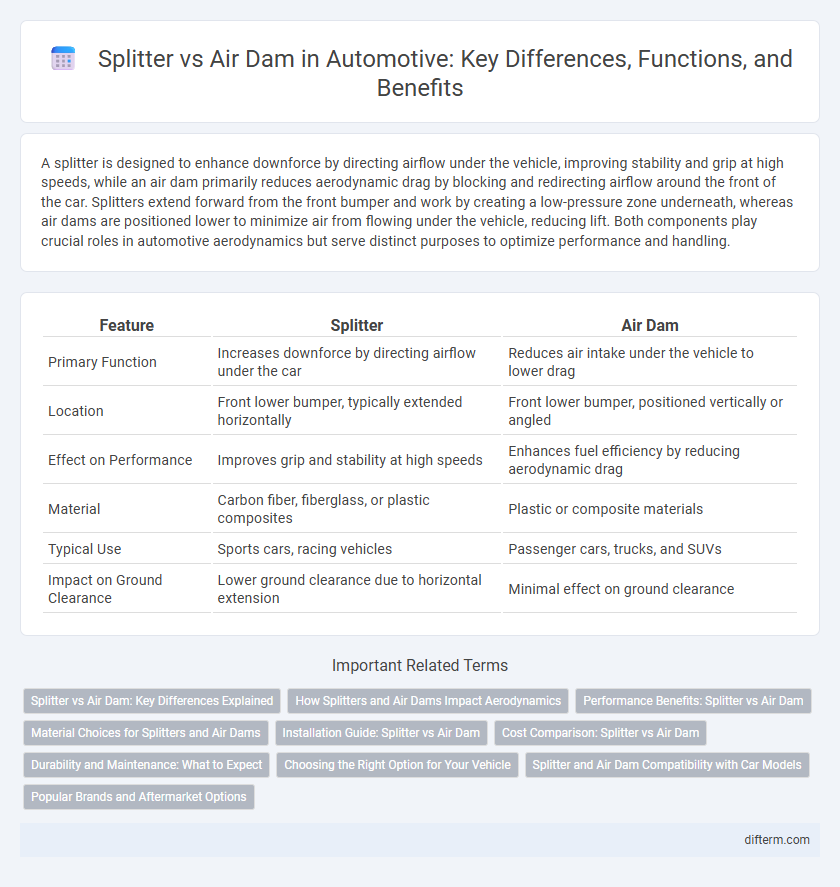

Table of Comparison

| Feature | Splitter | Air Dam |

|---|---|---|

| Primary Function | Increases downforce by directing airflow under the car | Reduces air intake under the vehicle to lower drag |

| Location | Front lower bumper, typically extended horizontally | Front lower bumper, positioned vertically or angled |

| Effect on Performance | Improves grip and stability at high speeds | Enhances fuel efficiency by reducing aerodynamic drag |

| Material | Carbon fiber, fiberglass, or plastic composites | Plastic or composite materials |

| Typical Use | Sports cars, racing vehicles | Passenger cars, trucks, and SUVs |

| Impact on Ground Clearance | Lower ground clearance due to horizontal extension | Minimal effect on ground clearance |

Splitter vs Air Dam: Key Differences Explained

A splitter is a horizontal component mounted at the front bottom of a vehicle to generate downforce by directing airflow underneath, improving traction and stability at high speeds. An air dam, positioned vertically and typically above or integrated with the bumper, reduces aerodynamic drag by limiting air from flowing beneath the car, enhancing fuel efficiency and vehicle cooling. Both play crucial aerodynamic roles but differ in placement, function, and impact on performance metrics such as downforce and drag reduction.

How Splitters and Air Dams Impact Aerodynamics

Splitters and air dams both enhance vehicle aerodynamics by managing airflow but serve distinct functions; splitters extend forward from the lower front bumper to increase downforce by directing air over the car, reducing lift and improving traction at high speeds. Air dams are positioned lower on the front bumper and focus on reducing air flow underneath the vehicle, minimizing drag and preventing front-end lift. Together, these components optimize stability, handling, and fuel efficiency in automotive design.

Performance Benefits: Splitter vs Air Dam

A splitter enhances downforce by directing airflow underneath the vehicle, improving front-end grip and high-speed stability, essential for track performance. An air dam primarily reduces aerodynamic drag and prevents airflow from entering the undercarriage, helping improve fuel efficiency and reducing lift at lower speeds. Compared to air dams, splitters offer more significant performance benefits in aggressive cornering and high-speed handling by optimizing aerodynamic balance and vehicle control.

Material Choices for Splitters and Air Dams

Splitters and air dams commonly utilize high-strength materials such as carbon fiber, fiberglass, and reinforced plastics to balance durability and weight reduction in automotive performance applications. Carbon fiber offers exceptional stiffness and lightweight properties ideal for racing vehicles, while fiberglass provides a cost-effective yet resilient option for street cars. Thermoplastic composites improve impact resistance and flexibility, enhancing performance in varying driving conditions.

Installation Guide: Splitter vs Air Dam

When installing a splitter versus an air dam, precise mounting points and vehicle compatibility are crucial for optimal performance and safety. Splitters typically attach directly to the front bumper or frame using brackets and bolts, requiring careful alignment to ensure aerodynamic efficiency and ground clearance. Air dams mount lower on the front fascia, often using clips or screws for a snug fit that reduces airflow under the vehicle, improving stability without extensive modifications.

Cost Comparison: Splitter vs Air Dam

Splitters generally cost more than air dams due to their complex design and use of durable materials like carbon fiber or reinforced plastics. Air dams are typically less expensive, made from simpler plastic or fiberglass components, and thus are a cost-effective option for basic aerodynamic improvements. Investing in a splitter offers enhanced downforce and stability, justifying the higher price for performance-focused automotive applications.

Durability and Maintenance: What to Expect

Splitters and air dams differ significantly in durability and maintenance requirements, with splitters generally made from more robust materials like carbon fiber or aluminum, offering enhanced resistance to impact and wear. Air dams, often constructed from plastic or composite materials, tend to be more susceptible to cracking or damage from road debris, necessitating more frequent inspections and repairs. Selecting a splitter can reduce long-term maintenance costs, while air dams might demand quicker replacements due to their lower durability in harsh driving conditions.

Choosing the Right Option for Your Vehicle

Selecting between a splitter and an air dam depends on your vehicle's performance goals and aerodynamic needs; splitters enhance front downforce by directing airflow under the car, improving high-speed stability and cornering grip. Air dams reduce airflow under the vehicle, lowering drag and improving fuel efficiency, making them suitable for street-driven cars. Evaluating factors such as track use, driving environment, and desired handling characteristics will guide you to the optimal aerodynamic setup for your vehicle.

Splitter and Air Dam Compatibility with Car Models

Splitters and air dams enhance automotive aerodynamics by managing airflow, but their compatibility varies across car models due to differences in front-end design and mounting points. Splitters typically require flat, extended front bumpers to attach securely and optimize downforce, whereas air dams are more adaptable to a wider range of vehicles, installed lower to reduce lift and direct air around the car. Selecting the correct component depends on the car's make, model, and aftermarket modifications, ensuring proper fitment and aerodynamic efficiency.

Popular Brands and Aftermarket Options

Popular automotive brands such as BMW, Audi, and Ford offer factory-installed splitters designed to enhance aerodynamics by directing airflow and increasing front-end downforce. Aftermarket options from manufacturers like APR Performance, Seibon, and Maxton Design provide a wide range of customizable splitters and air dams compatible with various vehicle models, catering to enthusiasts seeking improved handling and aggressive styling. These aftermarket components often use lightweight materials like carbon fiber or ABS plastic to balance performance gains with durability and weight reduction.

splitter vs air dam Infographic

difterm.com

difterm.com