CANbus offers higher data transfer speeds and robustness, making it ideal for critical automotive applications such as engine control and safety systems. LIN bus is a cost-effective, lower-speed network used primarily for non-critical functions like door locks and interior lighting. Understanding the trade-offs between CANbus and LIN bus helps optimize vehicle communication networks for performance and cost-efficiency.

Table of Comparison

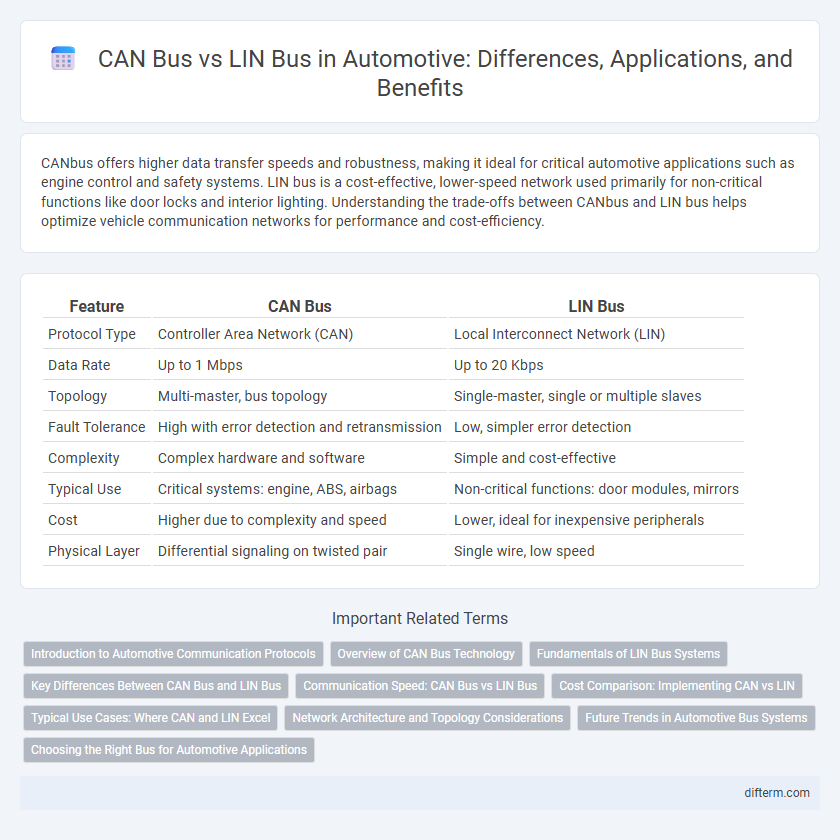

| Feature | CAN Bus | LIN Bus |

|---|---|---|

| Protocol Type | Controller Area Network (CAN) | Local Interconnect Network (LIN) |

| Data Rate | Up to 1 Mbps | Up to 20 Kbps |

| Topology | Multi-master, bus topology | Single-master, single or multiple slaves |

| Fault Tolerance | High with error detection and retransmission | Low, simpler error detection |

| Complexity | Complex hardware and software | Simple and cost-effective |

| Typical Use | Critical systems: engine, ABS, airbags | Non-critical functions: door modules, mirrors |

| Cost | Higher due to complexity and speed | Lower, ideal for inexpensive peripherals |

| Physical Layer | Differential signaling on twisted pair | Single wire, low speed |

Introduction to Automotive Communication Protocols

CAN bus and LIN bus are essential automotive communication protocols designed for in-vehicle networking. CAN bus offers high-speed, robust communication for critical systems like engine control and braking, supporting multi-master topology and error detection. LIN bus, optimized for simpler applications such as window controls and seat adjustments, provides a cost-effective, single-master, low-speed communication solution.

Overview of CAN Bus Technology

CAN Bus technology, a robust vehicle bus standard, facilitates efficient communication among microcontrollers and devices without a host computer. Operating at speeds up to 1 Mbps, it ensures reliable real-time data exchange in automotive systems like engine management, anti-lock braking, and airbags. Its multi-master, message-oriented protocol supports fault confinement and error detection, making it ideal for complex network environments compared to LIN Bus's simpler, lower-speed control applications.

Fundamentals of LIN Bus Systems

LIN bus systems operate as a cost-effective, single-wire communication protocol designed for low-speed networking in automotive applications, primarily managing body electronics like door modules, climate controls, and seat adjustments. Unlike the higher-speed CAN bus, LIN employs a master-slave architecture with a typical data rate of up to 20 Kbps, optimizing simplicity and reducing wiring complexity. LIN's synchronization, checksum error detection, and standardized frame format ensure reliable communication for non-critical functions within vehicle subsystems.

Key Differences Between CAN Bus and LIN Bus

CAN Bus offers high-speed communication up to 1 Mbps, suitable for critical vehicle systems such as engine control and ABS, while LIN Bus operates at a lower speed of 20 Kbps, designed for simpler, cost-sensitive applications like window controls and seat adjustments. CAN Bus supports multi-master architecture with error detection and fault confinement features, ensuring robust and reliable data exchange, whereas LIN Bus uses a single-master, multiple-slave configuration with limited error handling capabilities. The complexity and cost of CAN Bus are higher due to advanced protocol and hardware requirements, making LIN Bus a more economical choice for non-critical vehicle subsystems.

Communication Speed: CAN Bus vs LIN Bus

CAN bus supports high-speed communication up to 1 Mbps, enabling rapid data exchange for critical automotive systems like engine control and braking. LIN bus operates at a slower rate, typically capped at 20 Kbps, suitable for simpler, lower bandwidth applications such as window controls and seat adjustments. The speed difference impacts system design choices, with CAN bus favored for real-time performance and LIN bus preferred for cost-effective, non-critical communication.

Cost Comparison: Implementing CAN vs LIN

LIN bus offers a lower implementation cost compared to CAN bus due to its simpler protocol and reduced hardware requirements, making it ideal for cost-sensitive automotive applications with low-speed communication needs. CAN bus incurs higher expenses from advanced controllers and transceivers designed for robust, high-speed data transfer and error handling, suitable for complex vehicle networks. The overall system cost varies significantly as LIN's cost-effectiveness favors decentralized control systems, whereas CAN supports extensive, high-performance automotive communication architectures.

Typical Use Cases: Where CAN and LIN Excel

CAN bus excels in engine control, ABS, and transmission systems requiring high-speed data exchange for safety-critical functions. LIN bus is ideal for lower-speed applications like window controls, seat adjustments, and lighting systems where simplicity and cost-efficiency are prioritized. Both buses complement each other by optimizing communication networks in modern automotive electronic architectures.

Network Architecture and Topology Considerations

CAN bus supports a robust multi-master, multi-drop network architecture with a linear bus topology optimized for high-speed communication and fault tolerance among various automotive control units. LIN bus employs a simpler master-slave linear topology, designed for cost-effective, low-speed communication in body electronics and comfort systems where timing and error handling requirements are less stringent. Choosing between CAN and LIN depends on network complexity, data rate needs, and fault tolerance priorities within automotive electrical architectures.

Future Trends in Automotive Bus Systems

Future trends in automotive bus systems emphasize the evolution from traditional CAN bus to LIN bus integration for enhanced subsystem communication efficiency. LIN bus offers cost-effective, low-speed networking suited for body control applications while CAN bus continues to dominate powertrain and safety-critical systems with higher data rates and robustness. Emerging protocols focus on higher bandwidth, increased security features, and the integration of Ethernet to support advanced driver-assistance systems (ADAS) and autonomous vehicle architectures.

Choosing the Right Bus for Automotive Applications

CAN bus offers high-speed communication and robust error handling, making it ideal for critical automotive systems requiring real-time data exchange such as engine control and safety features. LIN bus provides a cost-effective, simpler alternative suited for low-speed, less complex networks like window controls and seat adjustments. Selecting the right bus depends on factors including data speed, network complexity, and cost constraints relevant to specific automotive applications.

canbus vs LIN bus Infographic

difterm.com

difterm.com