Gasoline Particulate Filters (GPF) and Diesel Particulate Filters (DPF) serve crucial roles in reducing vehicle emissions by capturing particulate matter, but they target different engine types and pollutants. GPFs are designed specifically for gasoline engines to filter out fine soot particles, improving air quality and meeting stricter emissions regulations. In contrast, DPFs are engineered for diesel engines, effectively trapping larger soot particles and requiring periodic regeneration to maintain performance and prevent clogging.

Table of Comparison

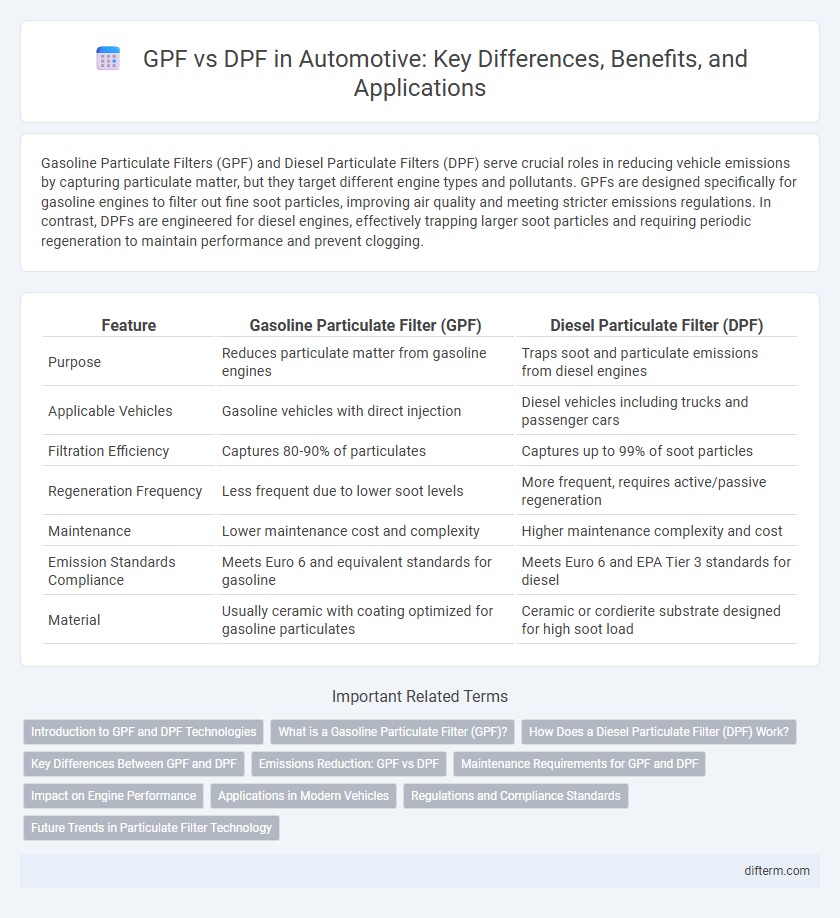

| Feature | Gasoline Particulate Filter (GPF) | Diesel Particulate Filter (DPF) |

|---|---|---|

| Purpose | Reduces particulate matter from gasoline engines | Traps soot and particulate emissions from diesel engines |

| Applicable Vehicles | Gasoline vehicles with direct injection | Diesel vehicles including trucks and passenger cars |

| Filtration Efficiency | Captures 80-90% of particulates | Captures up to 99% of soot particles |

| Regeneration Frequency | Less frequent due to lower soot levels | More frequent, requires active/passive regeneration |

| Maintenance | Lower maintenance cost and complexity | Higher maintenance complexity and cost |

| Emission Standards Compliance | Meets Euro 6 and equivalent standards for gasoline | Meets Euro 6 and EPA Tier 3 standards for diesel |

| Material | Usually ceramic with coating optimized for gasoline particulates | Ceramic or cordierite substrate designed for high soot load |

Introduction to GPF and DPF Technologies

Gasoline Particulate Filters (GPF) and Diesel Particulate Filters (DPF) are essential emissions control technologies designed to capture particulate matter from exhaust gases in gasoline and diesel engines, respectively. GPFs target fine soot particles generated by direct injection gasoline engines, reducing particulate emissions and meeting stringent Euro 6 and EPA Tier 3 standards. DPFs, utilized in diesel vehicles, trap larger soot particles through a porous ceramic filter and periodically regenerate by burning off accumulated particulates to maintain efficiency and comply with regulations like Euro 6d and EPA 2021 standards.

What is a Gasoline Particulate Filter (GPF)?

A Gasoline Particulate Filter (GPF) is an advanced emission control device designed to capture and reduce particulate matter (PM) from gasoline direct injection (GDI) engines. It operates by trapping fine soot particles in a porous filter substrate before they are released into the atmosphere, significantly lowering PM emissions. GPF technology is critical for meeting stringent European Union and global emission standards, contributing to cleaner air and improved environmental compliance in modern gasoline-powered vehicles.

How Does a Diesel Particulate Filter (DPF) Work?

A Diesel Particulate Filter (DPF) captures and stores exhaust soot to reduce emissions from diesel engines. It works by trapping particulate matter in a porous ceramic honeycomb structure, which is periodically heated during regeneration to burn off accumulated soot, transforming it into harmless carbon dioxide. This process ensures compliance with stringent Euro 6 emission standards while maintaining engine performance and fuel efficiency.

Key Differences Between GPF and DPF

Gasoline Particulate Filters (GPF) and Diesel Particulate Filters (DPF) differ primarily in their application and filtration efficiency, with GPFs designed for gasoline engines to trap fine particulate matter and DPFs for diesel engines to capture larger soot particles. DPF systems typically incorporate active regeneration processes to burn off accumulated soot, whereas GPFs often rely on passive filtration due to lower particulate output in gasoline engines. Material composition and operating temperatures also vary, with DPFs built to withstand higher thermal loads compared to the generally lower endurance requirements of GPFs.

Emissions Reduction: GPF vs DPF

Gasoline Particulate Filters (GPF) and Diesel Particulate Filters (DPF) effectively reduce particulate matter emissions by capturing soot and other fine particles from exhaust gases. While DPFs are designed to tackle higher soot loads typical of diesel engines, GPFs target finer particulates from gasoline direct injection engines, leading to significant reductions in ultra-fine particle emissions. Both filters contribute substantially to meeting stringent Euro 6 and Tier 3 emission standards by lowering PM emissions and improving air quality in urban environments.

Maintenance Requirements for GPF and DPF

Gasoline Particulate Filters (GPF) require regular inspection and occasional cleaning to prevent clogging from soot accumulation, typically every 50,000 to 100,000 kilometers depending on driving conditions. Diesel Particulate Filters (DPF) demand more frequent maintenance including active regeneration cycles to burn off trapped particulates and periodic professional cleaning to avoid blockage and engine performance issues. Both systems rely on proper fuel quality and driving patterns to optimize filter lifespan and reduce maintenance frequency.

Impact on Engine Performance

Gasoline Particulate Filters (GPF) and Diesel Particulate Filters (DPF) significantly influence engine performance by managing particulate emissions specific to gasoline and diesel engines respectively. GPFs are designed to handle lower soot volumes typical of gasoline engines, resulting in less back pressure and minimal impact on fuel efficiency and power output compared to DPFs, which face higher soot loads requiring more frequent regeneration and potentially greater back pressure. Efficient operation of both filters ensures compliance with emission standards while maintaining optimal engine performance and fuel economy.

Applications in Modern Vehicles

Gasoline Particulate Filters (GPF) and Diesel Particulate Filters (DPF) are critical emissions control technologies tailored for modern gasoline and diesel engines, respectively. GPFs effectively reduce particulate matter in direct-injection gasoline engines, meeting stringent Euro 6 and EPA Tier 3 standards, while DPFs are essential for diesel vehicles to trap soot and comply with Euro 6d and EPA 2010 regulations. The integration of GPFs and DPFs enhances air quality by significantly lowering harmful particulate emissions across passenger cars, light trucks, and commercial vehicles in urban and highway driving conditions.

Regulations and Compliance Standards

Gasoline Particulate Filters (GPF) and Diesel Particulate Filters (DPF) are critical for meeting stringent emissions regulations such as Euro 6 and EPA Tier 3 standards. GPFs primarily address particulate matter (PM) from direct-injection gasoline engines, while DPFs are designed for diesel vehicles to capture soot and meet stricter NOx and PM limits. Compliance with these global standards ensures reduced environmental impact and avoids penalties, driving manufacturers to innovate effective filtration technologies for both petrol and diesel powertrains.

Future Trends in Particulate Filter Technology

Gasoline Particulate Filters (GPFs) and Diesel Particulate Filters (DPFs) are evolving with advancements in nanotechnology and sensor integration to enhance filtration efficiency and reduce regeneration frequency. Emerging materials such as silicon carbide and metal-organic frameworks are being developed to improve durability and lower backpressure in both GPFs and DPFs. Future trends also emphasize real-time monitoring and adaptive filtering systems to comply with increasingly stringent emissions regulations worldwide.

GPF vs DPF Infographic

difterm.com

difterm.com