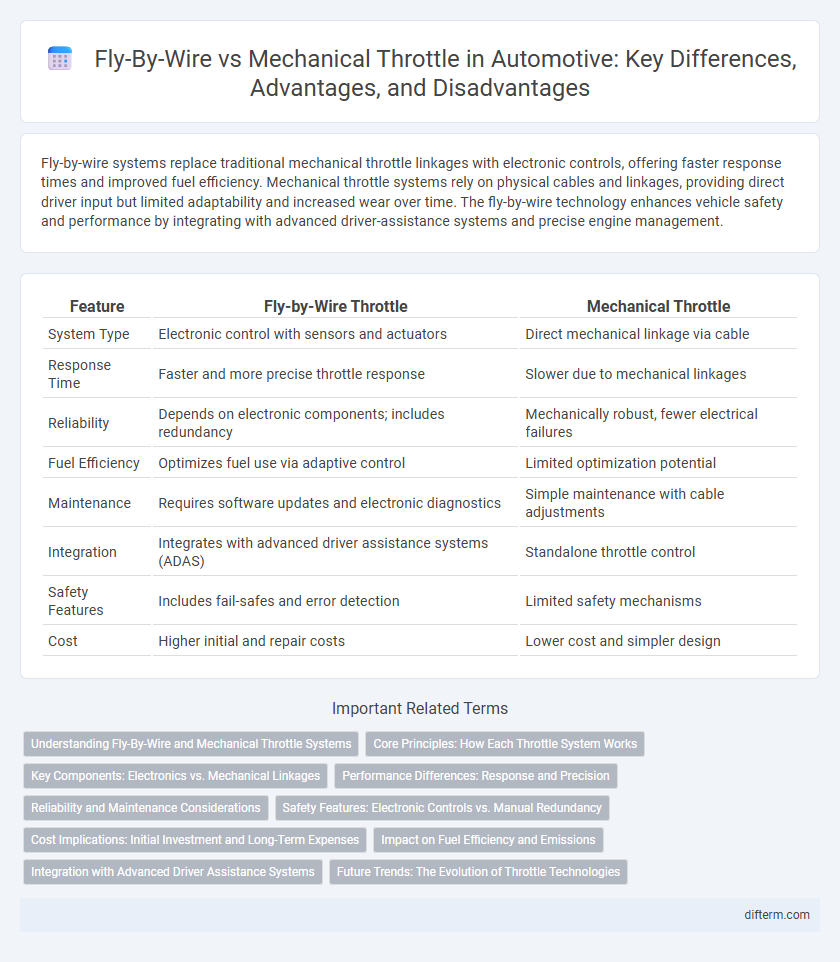

Fly-by-wire systems replace traditional mechanical throttle linkages with electronic controls, offering faster response times and improved fuel efficiency. Mechanical throttle systems rely on physical cables and linkages, providing direct driver input but limited adaptability and increased wear over time. The fly-by-wire technology enhances vehicle safety and performance by integrating with advanced driver-assistance systems and precise engine management.

Table of Comparison

| Feature | Fly-by-Wire Throttle | Mechanical Throttle |

|---|---|---|

| System Type | Electronic control with sensors and actuators | Direct mechanical linkage via cable |

| Response Time | Faster and more precise throttle response | Slower due to mechanical linkages |

| Reliability | Depends on electronic components; includes redundancy | Mechanically robust, fewer electrical failures |

| Fuel Efficiency | Optimizes fuel use via adaptive control | Limited optimization potential |

| Maintenance | Requires software updates and electronic diagnostics | Simple maintenance with cable adjustments |

| Integration | Integrates with advanced driver assistance systems (ADAS) | Standalone throttle control |

| Safety Features | Includes fail-safes and error detection | Limited safety mechanisms |

| Cost | Higher initial and repair costs | Lower cost and simpler design |

Understanding Fly-By-Wire and Mechanical Throttle Systems

Fly-by-wire throttle systems use electronic sensors and actuators to control engine power, offering precise throttle response and easier integration with advanced driver-assistance systems. Mechanical throttle systems rely on direct physical connections, such as cables, to link the accelerator pedal to the throttle valve, ensuring a straightforward and reliable operation. Understanding these differences highlights fly-by-wire's benefits in enhancing fuel efficiency and emissions control compared to the simplicity and robustness of mechanical throttles.

Core Principles: How Each Throttle System Works

Fly-by-wire throttle systems use electronic sensors and actuators to control engine power, replacing traditional mechanical linkages with digital signals for precise and responsive throttle input. Mechanical throttle systems rely on physical cables connected directly from the accelerator pedal to the engine's throttle body, ensuring a direct mechanical connection for immediate engine response. Fly-by-wire technology enables advanced features like adaptive cruise control and stability management by integrating with the vehicle's electronic control units (ECUs) for optimized performance and safety.

Key Components: Electronics vs. Mechanical Linkages

Fly-by-wire throttle systems rely on electronic sensors, actuators, and control units to precisely regulate engine power, replacing traditional mechanical linkages found in conventional throttles. These advanced electronics enhance responsiveness, enable integration with vehicle stability systems, and reduce mechanical wear, improving overall reliability and performance. Mechanical throttle systems use direct cable connections between the accelerator pedal and throttle body, offering simplicity but limited adaptability compared to electronic controls.

Performance Differences: Response and Precision

Fly-by-wire throttle systems deliver faster response times and enhanced precision compared to traditional mechanical throttles, as electronic sensors instantly interpret driver input and adjust engine output without mechanical lag. This improved responsiveness allows for smoother acceleration and finer control over power delivery, especially beneficial in high-performance and racing vehicles. Moreover, fly-by-wire technology enables adaptive throttle mapping, optimizing performance based on driving conditions and driver preferences.

Reliability and Maintenance Considerations

Fly-by-wire throttles offer enhanced reliability due to fewer mechanical components susceptible to wear and easier integration with diagnostic systems, allowing for proactive maintenance. Mechanical throttles require regular physical inspections and adjustments to maintain performance, increasing maintenance time and potential for mechanical failure. The electronic nature of fly-by-wire systems reduces mechanical linkage degradation, leading to lower long-term maintenance costs and improved vehicle uptime.

Safety Features: Electronic Controls vs. Manual Redundancy

Fly-by-wire systems enhance safety through precise electronic controls that enable real-time monitoring and fault detection, reducing the risk of throttle malfunctions. Mechanical throttles rely on manual redundancy, such as cable backups, to ensure operation during failures but lack the advanced diagnostic capabilities of electronic systems. The integration of sensors and automated feedback loops in fly-by-wire technology offers superior reliability and quicker response times compared to traditional mechanical linkages.

Cost Implications: Initial Investment and Long-Term Expenses

Fly-by-wire throttle systems typically incur a higher initial investment compared to mechanical throttles due to advanced sensor integration and electronic control units. Long-term expenses for fly-by-wire are often lower because of reduced maintenance needs and improved fuel efficiency through precise throttle management. Mechanical throttle systems exhibit lower upfront costs but may experience higher maintenance and adjustment expenses over vehicle lifespan.

Impact on Fuel Efficiency and Emissions

Fly-by-wire throttle systems enable precise control of engine performance through electronic signals, resulting in optimized fuel injection and combustion processes that enhance fuel efficiency compared to mechanical throttles. The improved accuracy in throttle response reduces unnecessary fuel consumption and minimizes emissions by maintaining optimal air-fuel ratios under varying driving conditions. Studies indicate vehicles equipped with fly-by-wire technology demonstrate lower CO2 emissions and better mileage, supporting environmental sustainability and regulatory compliance.

Integration with Advanced Driver Assistance Systems

Fly-by-wire throttle systems offer seamless integration with Advanced Driver Assistance Systems (ADAS) by enabling precise electronic control and real-time data exchange between the vehicle's sensors and engine management. Mechanical throttles lack this capability, making it challenging to coordinate adaptive cruise control, collision avoidance, and lane-keeping assist effectively. Enhanced responsiveness and safety in modern vehicles are largely attributed to the digital communication facilitated by fly-by-wire technology.

Future Trends: The Evolution of Throttle Technologies

Fly-by-wire throttle systems leverage electronic signals to replace mechanical linkages, enhancing precision and enabling seamless integration with advanced driver-assistance systems and autonomous driving technologies. Future trends indicate a shift towards fully electronic throttle controls that improve fuel efficiency and reduce emissions through adaptive engine management. Emerging developments in AI-driven predictive throttle response and enhanced cybersecurity protocols further drive the evolution of throttle technologies in modern automotive design.

fly-by-wire vs mechanical throttle Infographic

difterm.com

difterm.com