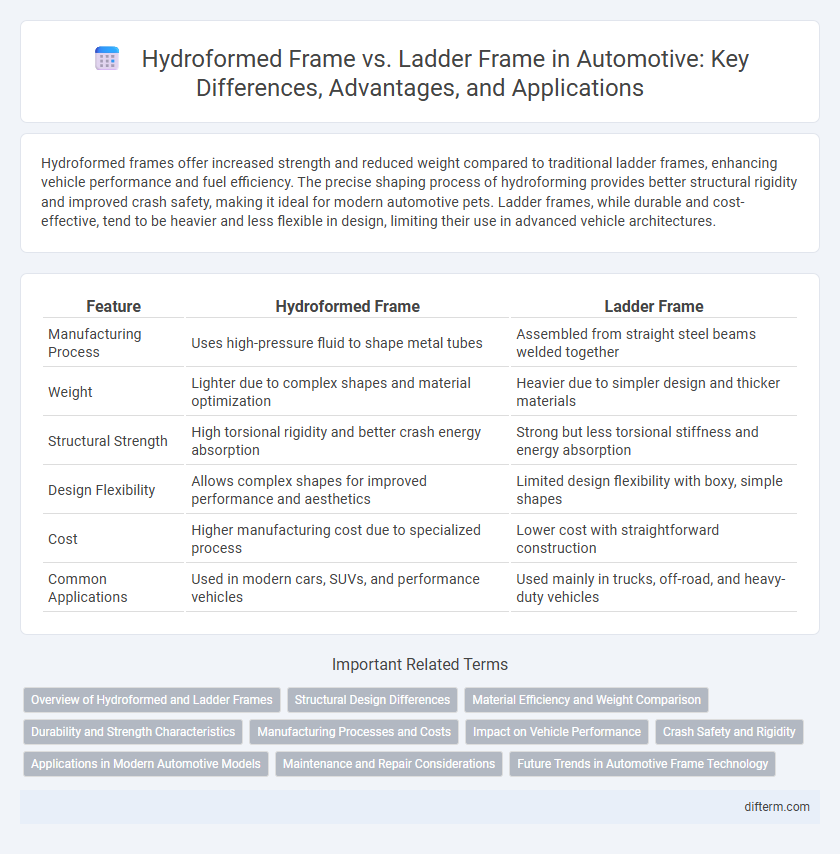

Hydroformed frames offer increased strength and reduced weight compared to traditional ladder frames, enhancing vehicle performance and fuel efficiency. The precise shaping process of hydroforming provides better structural rigidity and improved crash safety, making it ideal for modern automotive pets. Ladder frames, while durable and cost-effective, tend to be heavier and less flexible in design, limiting their use in advanced vehicle architectures.

Table of Comparison

| Feature | Hydroformed Frame | Ladder Frame |

|---|---|---|

| Manufacturing Process | Uses high-pressure fluid to shape metal tubes | Assembled from straight steel beams welded together |

| Weight | Lighter due to complex shapes and material optimization | Heavier due to simpler design and thicker materials |

| Structural Strength | High torsional rigidity and better crash energy absorption | Strong but less torsional stiffness and energy absorption |

| Design Flexibility | Allows complex shapes for improved performance and aesthetics | Limited design flexibility with boxy, simple shapes |

| Cost | Higher manufacturing cost due to specialized process | Lower cost with straightforward construction |

| Common Applications | Used in modern cars, SUVs, and performance vehicles | Used mainly in trucks, off-road, and heavy-duty vehicles |

Overview of Hydroformed and Ladder Frames

Hydroformed frames use high-pressure fluid to shape lightweight, tubular steel components that enhance structural rigidity and reduce vehicle weight, improving fuel efficiency and handling. Ladder frames consist of two parallel steel beams connected by cross members, providing durability and strength ideal for heavy-duty and off-road applications. Hydroformed frames offer better crash energy management and design flexibility compared to the traditional ladder frame architecture.

Structural Design Differences

Hydroformed frames are created using high-pressure fluid to shape tubular steel into complex, lightweight, and rigid structures, enhancing torsional stiffness and crashworthiness compared to traditional ladder frames. Ladder frames consist of two parallel steel beams connected by crossmembers, offering robustness and simplicity but increased weight and less resistance to flex under stress. The hydroforming process allows for more precise control over frame geometry, resulting in improved vehicle handling and safety performance.

Material Efficiency and Weight Comparison

Hydroformed frames utilize precision-shaped steel or aluminum tubing to create lightweight, high-strength structures that optimize material usage and reduce overall vehicle weight. Ladder frames, typically constructed from heavier stamped steel sections, offer robust durability but result in increased material consumption and higher vehicle mass. The superior material efficiency of hydroformed frames contributes to enhanced fuel economy and improved handling performance compared to traditional ladder frame designs.

Durability and Strength Characteristics

Hydroformed frames offer superior durability and strength compared to traditional ladder frames due to their seamless, tubular construction, which provides enhanced rigidity and better resistance to twisting and impact forces. Hydroforming allows for precise control over frame geometry, resulting in optimized stress distribution and improved crash energy absorption. Ladder frames, while robust, typically exhibit lower torsional stiffness and higher susceptibility to fatigue over time, making hydroformed frames the preferred choice for modern vehicles requiring enhanced structural integrity.

Manufacturing Processes and Costs

Hydroformed frames utilize high-pressure fluid to shape metal tubes into complex, lightweight structures, resulting in fewer welds and reduced material waste compared to traditional ladder frames. Ladder frames, formed through simpler stamping and welding of flat steel sections, generally incur lower initial tooling costs but higher material usage and weight, impacting fuel efficiency. The advanced hydroforming process increases upfront manufacturing investment while delivering long-term cost savings through improved structural integrity and reduced assembly time.

Impact on Vehicle Performance

Hydroformed frames provide enhanced rigidity and reduced weight compared to traditional ladder frames, resulting in improved handling and fuel efficiency. Their seamless construction allows better force distribution during collisions, increasing overall vehicle safety. Ladder frames, while heavier and less rigid, offer superior durability and strength for heavy-duty applications and off-road performance.

Crash Safety and Rigidity

Hydroformed frames exhibit superior crash safety due to their uniform strength distribution and ability to efficiently absorb impact energy, reducing passenger injury risk. Their enhanced rigidity improves vehicle handling and structural integrity, minimizing chassis flex during collisions. Ladder frames, while durable, generally offer less rigidity and energy absorption, making hydroformed frames a preferred choice for modern automotive safety standards.

Applications in Modern Automotive Models

Hydroformed frames are widely used in modern automotive models to enhance structural rigidity and reduce vehicle weight, benefiting sports cars and luxury SUVs by providing improved handling and fuel efficiency. Ladder frames remain prevalent in heavy-duty trucks and off-road vehicles due to their robust construction and superior load-bearing capacity. The choice between hydroformed and ladder frames depends on the vehicle's performance requirements, with hydroforming favored for precision engineering and ladder frames for durability in demanding conditions.

Maintenance and Repair Considerations

Hydroformed frames offer enhanced rigidity and precision, resulting in fewer alignment issues and reduced maintenance frequency compared to traditional ladder frames. Ladder frames, while easier and cheaper to repair due to their simple design and widespread availability of parts, often require more frequent inspections and weld repairs following heavy use. Repair shops need specialized equipment and training to handle hydroformed frames, increasing repair costs but improving long-term vehicle durability.

Future Trends in Automotive Frame Technology

Hydroformed frames offer superior strength-to-weight ratios and enhanced rigidity, enabling automotive manufacturers to improve fuel efficiency and crash safety in next-generation vehicles. Ladder frames, traditionally favored for heavy-duty trucks, are evolving with advanced materials like high-strength steel and aluminum alloys to reduce weight while maintaining durability. Future trends in automotive frame technology emphasize hybrid construction techniques that combine hydroforming precision with ladder frame robustness to meet evolving performance and environmental standards.

hydroformed frame vs ladder frame Infographic

difterm.com

difterm.com