Closed deck engine blocks provide enhanced strength and rigidity by connecting the cylinder walls with additional material, making them ideal for high-performance automotive applications requiring durability under high pressure. Open deck designs allow better coolant flow around the cylinders, improving engine cooling efficiency and making them suitable for everyday automotive use and moderate power outputs. Choosing between closed deck vs open deck configurations depends on the balance between performance needs and thermal management priorities in automotive pet engines.

Table of Comparison

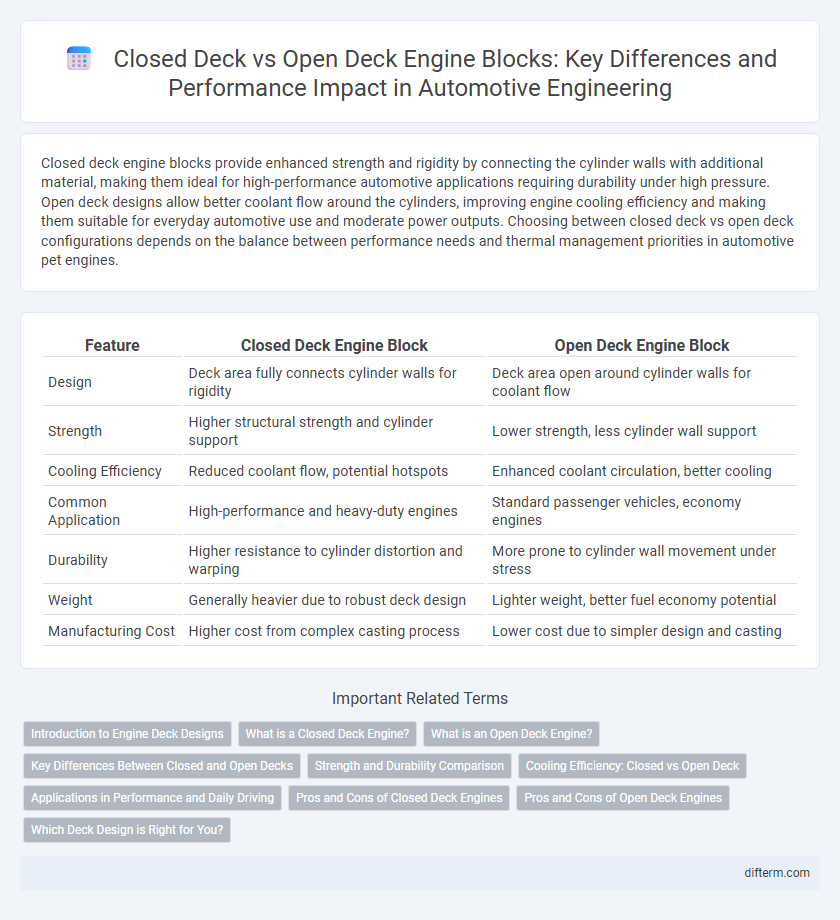

| Feature | Closed Deck Engine Block | Open Deck Engine Block |

|---|---|---|

| Design | Deck area fully connects cylinder walls for rigidity | Deck area open around cylinder walls for coolant flow |

| Strength | Higher structural strength and cylinder support | Lower strength, less cylinder wall support |

| Cooling Efficiency | Reduced coolant flow, potential hotspots | Enhanced coolant circulation, better cooling |

| Common Application | High-performance and heavy-duty engines | Standard passenger vehicles, economy engines |

| Durability | Higher resistance to cylinder distortion and warping | More prone to cylinder wall movement under stress |

| Weight | Generally heavier due to robust deck design | Lighter weight, better fuel economy potential |

| Manufacturing Cost | Higher cost from complex casting process | Lower cost due to simpler design and casting |

Introduction to Engine Deck Designs

Closed deck engine designs feature reinforced cylinder walls connected by a solid deck surface, offering enhanced strength and rigidity ideal for high-performance and forced induction engines. Open deck designs provide improved cooling efficiency by allowing coolant to flow freely around the cylinder walls, commonly utilized in mass-produced, naturally aspirated engines. The choice between closed and open deck configurations impacts engine durability, thermal management, and performance tuning possibilities.

What is a Closed Deck Engine?

A closed deck engine features a cylinder block design where the area around the cylinders is mostly solid, providing increased strength and reduced cylinder distortion under high pressure. This design improves durability and is commonly used in high-performance and forced induction applications. It enhances engine rigidity, helping to maintain optimum compression and combustion efficiency.

What is an Open Deck Engine?

An open deck engine features cylinder bores surrounded by coolant passages without solid material connecting the cylinder walls to the outer engine block, allowing improved coolant flow and heat dissipation. This design typically results in a lighter engine block, which benefits fuel efficiency and cost but may sacrifice some structural rigidity compared to closed deck engines. Open deck engines are commonly found in everyday passenger vehicles where balance between performance, cooling, and manufacturing cost is prioritized.

Key Differences Between Closed and Open Decks

Closed deck engine blocks feature reinforced cylinder walls with limited coolant flow passages, providing enhanced strength and rigidity ideal for high-performance and forced induction applications. Open deck designs offer improved coolant circulation around cylinders, promoting better engine cooling and reducing the risk of overheating under normal driving conditions. The primary trade-off lies in the closed deck's superior structural integrity versus the open deck's enhanced thermal management.

Strength and Durability Comparison

Closed deck engines offer superior strength and durability due to their reinforced cylinder walls that better resist warping and pressure, making them ideal for high-performance and heavy-duty applications. Open deck designs provide improved cooling but sacrifice some structural rigidity, which can lead to reduced longevity under extreme stress. The enhanced support in closed deck blocks significantly minimizes cylinder distortion, ensuring greater engine longevity and reliability in demanding automotive environments.

Cooling Efficiency: Closed vs Open Deck

Closed deck engine blocks provide superior cooling efficiency by minimizing coolant flow around the cylinders, resulting in better structural rigidity but potentially higher localized temperatures. Open deck designs enhance coolant circulation around the cylinder walls, improving heat dissipation and reducing the risk of overheating during high-performance or extended driving conditions. Optimizing cooling pathways in open deck blocks supports thermal management for turbocharged or high-compression engines, while closed decks prioritize durability and strength.

Applications in Performance and Daily Driving

Closed deck engine blocks provide enhanced structural rigidity and superior cooling control, making them ideal for high-performance applications like racing and turbocharged vehicles. Open deck designs offer improved heat dissipation and lighter weight, benefiting daily driving by promoting fuel efficiency and smooth engine operation. Selecting between closed and open deck configurations depends on balancing performance demands with everyday reliability and thermal management.

Pros and Cons of Closed Deck Engines

Closed deck engines offer superior block rigidity, enhancing strength and durability under high-performance conditions, especially in turbocharged or high-boost applications. They provide better coolant flow control, reducing the risk of head gasket failure and improving thermal management. However, closed deck designs can limit cylinder bore size and complicate machining processes, resulting in higher manufacturing costs and reduced ease of modification compared to open deck engines.

Pros and Cons of Open Deck Engines

Open deck engines offer improved cooling efficiency due to increased coolant flow around the cylinder walls, reducing the risk of overheating and warping. However, they typically have less block rigidity compared to closed deck designs, which can lead to lower structural strength and potential deformation under high-performance or high-stress conditions. The open deck configuration is often favored for everyday vehicles prioritizing cost-effectiveness and thermal management but may not suit high-horsepower applications requiring enhanced engine block durability.

Which Deck Design is Right for You?

Closed deck engine blocks provide enhanced strength and rigidity, making them ideal for high-performance or turbocharged vehicles that demand superior durability. Open deck designs offer better coolant flow and heat dissipation, which benefit everyday driving and moderate performance engines by maintaining optimal operating temperatures. Choosing the right deck design depends on your vehicle's performance requirements and cooling needs, with closed decks suited for heavy-duty applications and open decks favored for efficiency and longevity.

closed deck vs open deck Infographic

difterm.com

difterm.com