Slotted rotors provide enhanced heat dissipation and improved brake pad grip, making them ideal for aggressive driving and heavy braking conditions. Drilled rotors excel at reducing brake fade by allowing gases and water to escape, offering superior performance in wet conditions. Choosing between slotted and drilled rotors depends on driving style, climate, and performance needs.

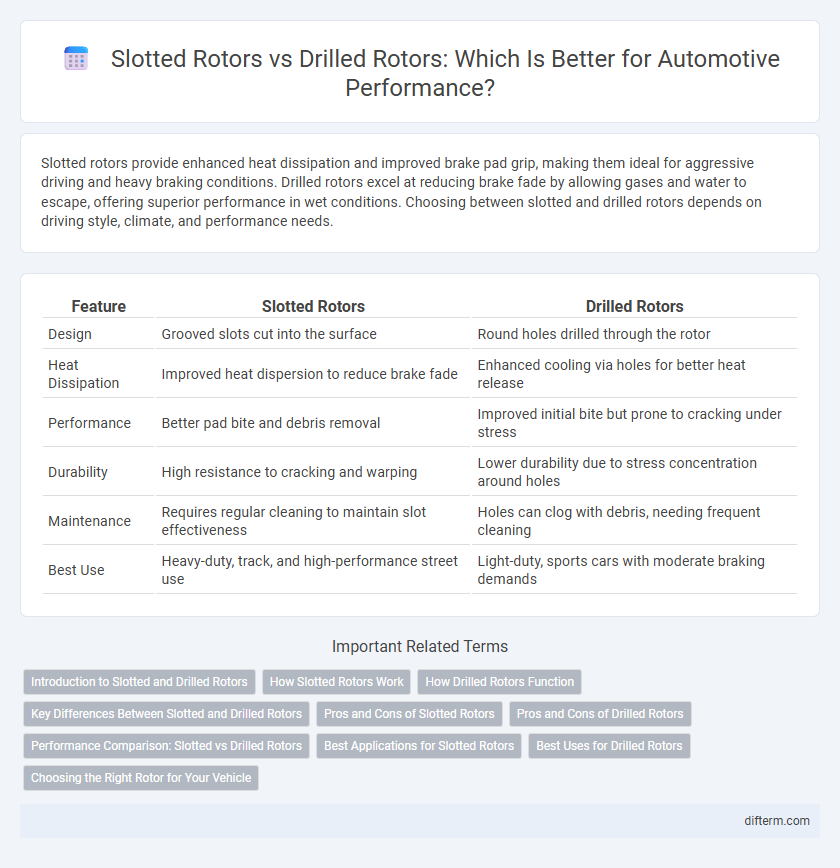

Table of Comparison

| Feature | Slotted Rotors | Drilled Rotors |

|---|---|---|

| Design | Grooved slots cut into the surface | Round holes drilled through the rotor |

| Heat Dissipation | Improved heat dispersion to reduce brake fade | Enhanced cooling via holes for better heat release |

| Performance | Better pad bite and debris removal | Improved initial bite but prone to cracking under stress |

| Durability | High resistance to cracking and warping | Lower durability due to stress concentration around holes |

| Maintenance | Requires regular cleaning to maintain slot effectiveness | Holes can clog with debris, needing frequent cleaning |

| Best Use | Heavy-duty, track, and high-performance street use | Light-duty, sports cars with moderate braking demands |

Introduction to Slotted and Drilled Rotors

Slotted and drilled rotors are critical components in automotive braking systems designed to enhance heat dissipation and improve stopping performance. Slotted rotors feature grooves that channel gases, dust, and water away from the braking surface, reducing brake fade and increasing pad bite. Drilled rotors contain holes that allow for better heat dissipation and water dispersion, though they may be more susceptible to cracking under extreme stress compared to slotted rotors.

How Slotted Rotors Work

Slotted rotors improve braking performance by channeling gases, dust, and water away from the rotor surface, ensuring consistent contact between brake pads and the rotor. Their strategically placed grooves enhance heat dissipation, reducing the risk of brake fade during high-performance or heavy-duty driving. This design promotes better brake pad bite and maintains optimal stopping power under demanding conditions.

How Drilled Rotors Function

Drilled rotors function by featuring multiple holes drilled through the rotor surface, which help dissipate heat generated during braking and reduce brake fade. These holes allow gases, water, and debris to escape, maintaining consistent friction between the brake pad and rotor for improved stopping performance. The specific design enhances cooling efficiency and ensures better performance in high-temperature and wet conditions within automotive braking systems.

Key Differences Between Slotted and Drilled Rotors

Slotted rotors feature grooves that improve brake pad bite and effectively channel dust, gas, and heat away from the braking surface for enhanced performance in aggressive driving. Drilled rotors have holes designed to dissipate heat and prevent brake fade by allowing air to circulate, making them suitable for high-performance and everyday use. The primary difference lies in cooling efficiency and durability, with slotted rotors offering better longevity under heavy braking conditions while drilled rotors provide quicker heat dissipation but can be more prone to cracking.

Pros and Cons of Slotted Rotors

Slotted rotors provide enhanced braking performance by improving heat dissipation and expelling gases, dust, and water from the brake pad surface, which helps maintain consistent friction under heavy braking conditions. They typically offer increased durability and reduced brake fade compared to drilled rotors, making them ideal for aggressive driving and track use. However, slotted rotors can cause faster brake pad wear and are generally noisier than drilled rotors, which may affect comfort during daily driving.

Pros and Cons of Drilled Rotors

Drilled rotors enhance heat dissipation and improve braking performance by allowing gases and debris to escape through the holes, reducing brake fade during intense use. However, their structural rigidity is compromised compared to solid or slotted rotors, making them more prone to cracking under extreme stress or prolonged high-temperature conditions. Ideal for light, high-performance driving, drilled rotors may not withstand heavy-duty or aggressive braking scenarios as effectively as slotted or solid alternatives.

Performance Comparison: Slotted vs Drilled Rotors

Slotted rotors enhance brake pad bite and improve gas and dust evacuation, resulting in consistent braking performance under high temperatures. Drilled rotors excel in heat dissipation due to their perforations, reducing brake fade and improving wet-weather braking efficiency. However, slotted rotors typically offer greater durability and resistance to cracking compared to drilled rotors, making them a preferred choice for aggressive driving and racing applications.

Best Applications for Slotted Rotors

Slotted rotors excel in high-performance and heavy-duty applications where consistent braking power and heat dissipation are critical. Their design enhances pad bite and helps remove gas, dust, and water from the rotor surface, making them ideal for racing, towing, and off-road conditions. Vehicles frequently exposed to harsh environments benefit most from slotted rotors due to their improved durability and braking reliability under extreme stress.

Best Uses for Drilled Rotors

Drilled rotors excel in high-performance and lightweight vehicles where heat dissipation and weight reduction are critical, as their perforations improve ventilation and help prevent brake fade during intense braking. They are best suited for sporty street driving and occasional track use, where enhanced cooling and water dispersion improve braking consistency in wet conditions. However, for aggressive off-road or heavy-duty applications, drilled rotors may be prone to cracking, making them less ideal compared to slotted alternatives.

Choosing the Right Rotor for Your Vehicle

Choosing the right rotor for your vehicle involves understanding the performance differences between slotted and drilled rotors. Slotted rotors provide enhanced brake pad grip and help expel gases, dirt, and water, making them ideal for heavy-duty and high-performance driving. Drilled rotors excel at heat dissipation and reducing brake fade but may be prone to cracking under extreme stress, so selecting based on driving conditions and vehicle type is crucial.

slotted rotors vs drilled rotors Infographic

difterm.com

difterm.com