FDM 3D printing excels in cost-effective prototyping and producing durable parts with thermoplastic materials, making it ideal for functional components and rapid iterations. SLA 3D printing offers superior precision and smooth surface finishes by curing resin with a UV laser, perfect for detailed models and intricate designs. Choosing between FDM and SLA depends on the required resolution, material properties, and application complexity.

Table of Comparison

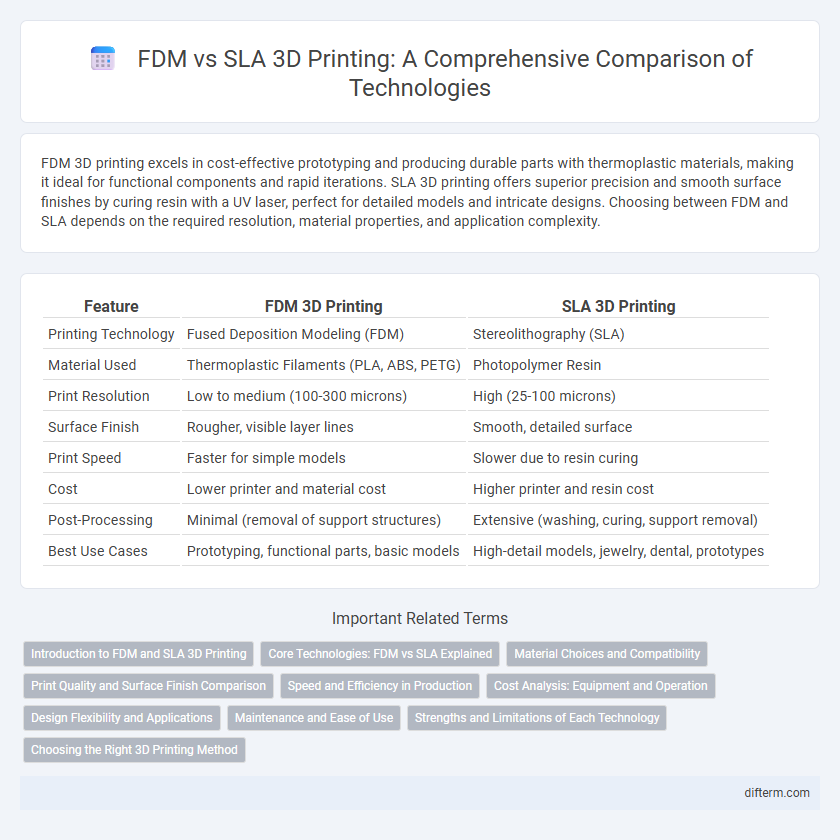

| Feature | FDM 3D Printing | SLA 3D Printing |

|---|---|---|

| Printing Technology | Fused Deposition Modeling (FDM) | Stereolithography (SLA) |

| Material Used | Thermoplastic Filaments (PLA, ABS, PETG) | Photopolymer Resin |

| Print Resolution | Low to medium (100-300 microns) | High (25-100 microns) |

| Surface Finish | Rougher, visible layer lines | Smooth, detailed surface |

| Print Speed | Faster for simple models | Slower due to resin curing |

| Cost | Lower printer and material cost | Higher printer and resin cost |

| Post-Processing | Minimal (removal of support structures) | Extensive (washing, curing, support removal) |

| Best Use Cases | Prototyping, functional parts, basic models | High-detail models, jewelry, dental, prototypes |

Introduction to FDM and SLA 3D Printing

FDM 3D printing uses thermoplastic filaments melted and extruded through a heated nozzle to build objects layer by layer, making it ideal for rapid prototyping and functional parts. SLA 3D printing relies on photopolymer resins cured by a UV laser or light source, producing high-resolution, smooth-surfaced models suited for detailed designs and molds. Both technologies serve distinct applications with FDM offering cost-effective, durable prints and SLA delivering superior precision and fine details.

Core Technologies: FDM vs SLA Explained

FDM 3D printing extrudes thermoplastic filaments layer by layer, utilizing a heated nozzle to build durable parts with high mechanical strength, ideal for prototyping and functional components. SLA 3D printing employs a laser to cure liquid resin photopolymer into precise, high-resolution models with smooth surface finishes, suitable for intricate designs and detailed prototypes. The fundamental difference lies in material states--FDM uses solid filaments melted and deposited, while SLA solidifies liquid resin through photopolymerization, influencing print resolution, speed, and application scopes.

Material Choices and Compatibility

FDM 3D printing primarily utilizes thermoplastic filaments such as PLA, ABS, and PETG, offering broad material compatibility ideal for functional prototypes and durable parts. SLA 3D printing employs photopolymer resins, including standard, flexible, castable, and biocompatible types, which enable high-resolution, detailed prints with smooth surface finishes. Material selection in FDM focuses on mechanical properties and strength, while SLA prioritizes precision and fine detail for applications like dental, jewelry, and intricate modeling.

Print Quality and Surface Finish Comparison

FDM 3D printing typically produces parts with visible layer lines and rougher surface finishes due to the extrusion-based process, making it ideal for functional prototypes rather than detailed models. SLA 3D printing uses a laser to cure resin, resulting in superior print quality with higher resolution, smoother surfaces, and intricate detail reproduction. Surface finish in SLA prints requires minimal post-processing, whereas FDM parts often need sanding or smoothing to achieve comparable aesthetics.

Speed and Efficiency in Production

FDM 3D printing offers faster production speeds due to its straightforward extrusion process, making it ideal for rapid prototyping and large parts. SLA 3D printing provides higher resolution and surface finish but involves longer curing and post-processing times, impacting overall efficiency. Choosing between FDM and SLA depends on the balance between speed requirements and the desired precision in production workflows.

Cost Analysis: Equipment and Operation

FDM 3D printing typically offers lower initial equipment costs, with printers ranging from $200 to $4,000, making it more accessible for beginners and small businesses, while SLA machines often start around $3,000 and can exceed $10,000 due to advanced resin curing technology. Operational costs for FDM are generally lower, as filament materials like PLA or ABS cost about $20 to $50 per kilogram, whereas SLA resins can range from $150 to $300 per liter, driving up the cost per print. Maintenance expenses also differ; FDM printers require periodic nozzle replacement and occasional bed leveling, whereas SLA machines need regular resin replacement, cleaning, and resin tank maintenance, increasing ongoing costs.

Design Flexibility and Applications

FDM 3D printing offers greater design flexibility for larger, industrial parts due to its ability to print with a wide range of thermoplastics and build sizes, making it ideal for prototyping functional components and durable end-use products. SLA 3D printing excels in creating highly detailed, intricate designs with smooth surface finishes, preferred for applications such as jewelry, dental models, and precise medical instruments. The choice between FDM and SLA hinges on the balance between required accuracy, material properties, and intended application requirements.

Maintenance and Ease of Use

FDM 3D printers generally offer easier maintenance due to their simpler mechanical structures and more accessible components, making routine tasks like nozzle cleaning and filament replacement straightforward. SLA 3D printers require more meticulous upkeep, including regular resin tank cleaning, careful handling of liquid resin, and post-processing steps such as washing and curing, which demand precision and time. Users seeking low-maintenance and straightforward operation often prefer FDM technology for its user-friendly setup and minimal post-printing requirements.

Strengths and Limitations of Each Technology

FDM 3D printing offers cost-effective production with durable, functional parts suited for prototyping and mechanical applications, but it often suffers from lower resolution and layer visibility. SLA 3D printing excels in high-detail accuracy and smooth surface finishes, making it ideal for intricate models and jewelry, though it generally involves higher material costs and slower build speeds. Both technologies present unique advantages and trade-offs depending on the application's precision requirements and material properties.

Choosing the Right 3D Printing Method

FDM 3D printing offers affordability and ease of use, making it ideal for prototyping and functional parts with durable thermoplastics like ABS and PLA. SLA 3D printing excels in producing high-resolution, detailed models with smooth surface finishes using photopolymer resins, perfect for intricate designs and fine features. Selecting the right 3D printing method depends on factors such as required precision, material properties, budget, and end-use application.

FDM 3D printing vs SLA 3D printing Infographic

difterm.com

difterm.com