Cross-docking in retail pet supply involves receiving products from suppliers and immediately transferring them to distribution trucks without long-term storage, optimizing inventory turnover and reducing warehousing costs. Direct Store Delivery bypasses distribution centers, allowing suppliers to deliver products straight to retail locations, enhancing freshness and enabling quicker replenishment of perishable pet items. Both methods improve supply chain efficiency but differ in inventory management and delivery speed.

Table of Comparison

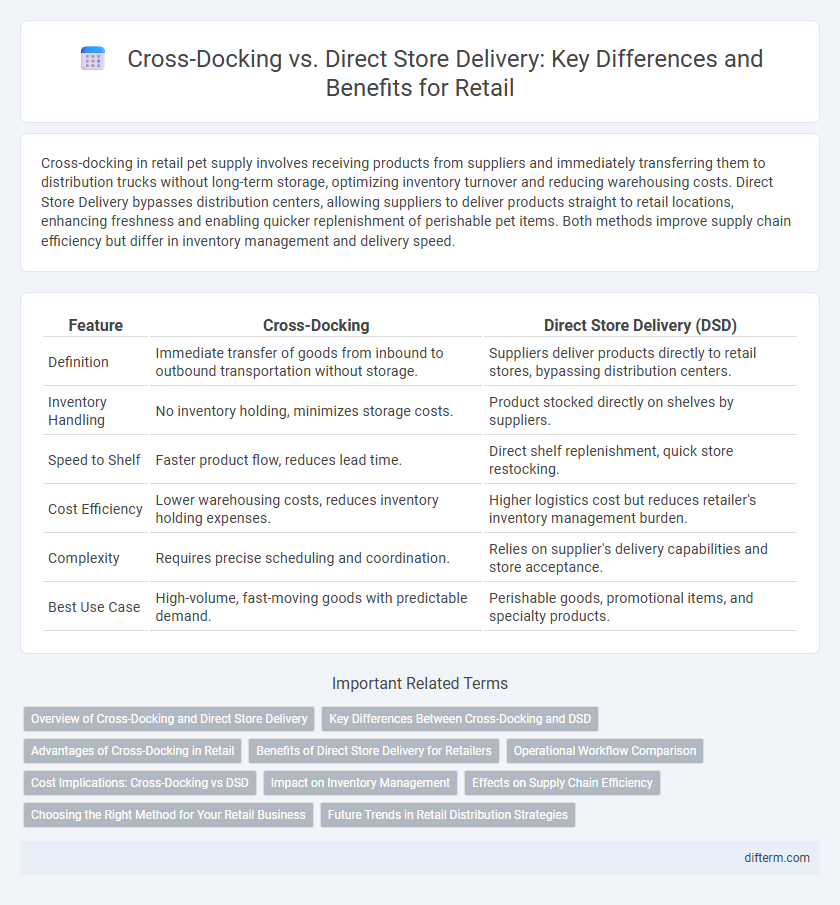

| Feature | Cross-Docking | Direct Store Delivery (DSD) |

|---|---|---|

| Definition | Immediate transfer of goods from inbound to outbound transportation without storage. | Suppliers deliver products directly to retail stores, bypassing distribution centers. |

| Inventory Handling | No inventory holding, minimizes storage costs. | Product stocked directly on shelves by suppliers. |

| Speed to Shelf | Faster product flow, reduces lead time. | Direct shelf replenishment, quick store restocking. |

| Cost Efficiency | Lower warehousing costs, reduces inventory holding expenses. | Higher logistics cost but reduces retailer's inventory management burden. |

| Complexity | Requires precise scheduling and coordination. | Relies on supplier's delivery capabilities and store acceptance. |

| Best Use Case | High-volume, fast-moving goods with predictable demand. | Perishable goods, promotional items, and specialty products. |

Overview of Cross-Docking and Direct Store Delivery

Cross-Docking minimizes storage by transferring products directly from inbound to outbound transportation, reducing inventory holding costs and speeding up delivery times. Direct Store Delivery (DSD) involves suppliers shipping products directly to retail stores, enhancing product freshness and accelerating replenishment cycles. Both logistics models optimize supply chain efficiency but differ in inventory handling and delivery control.

Key Differences Between Cross-Docking and DSD

Cross-Docking involves receiving products from suppliers and immediately transferring them to outbound trucks for distribution, minimizing storage and inventory handling. Direct Store Delivery (DSD) bypasses warehouses entirely by delivering products directly from the supplier to retail stores, enhancing freshness and speed for perishable goods. Key differences include inventory management, where Cross-Docking relies on centralized sorting while DSD emphasizes supplier-to-store logistics, and the type of products suited, with Cross-Docking favoring non-perishable fast-moving items and DSD targeting perishable or high-turnover products.

Advantages of Cross-Docking in Retail

Cross-Docking in retail reduces inventory holding costs by minimizing storage time, enabling faster product turnover and improved shelf availability. This logistics strategy enhances supply chain efficiency through streamlined handling and consolidated shipments, leading to lower transportation costs and reduced lead times. Retailers benefit from increased responsiveness to market demand fluctuations and improved customer satisfaction due to timely product replenishment.

Benefits of Direct Store Delivery for Retailers

Direct Store Delivery (DSD) streamlines inventory management by reducing warehouse handling and enabling faster restocking, which minimizes stockouts and enhances customer satisfaction. Retailers gain improved supply chain visibility and real-time data tracking, allowing for more accurate demand forecasting and inventory optimization. DSD also fosters stronger retailer-supplier relationships through direct communication, leading to better promotional execution and increased sales.

Operational Workflow Comparison

Cross-docking streamlines inventory management by transferring goods directly from inbound to outbound transportation, minimizing storage time and reducing handling costs. Direct Store Delivery (DSD) bypasses central warehouses, enabling suppliers to deliver products straight to retail stores, which accelerates product availability and enhances shelf freshness. Operational workflows for cross-docking emphasize synchronized scheduling and efficient dock management, while DSD prioritizes route optimization and rapid replenishment to meet store demands.

Cost Implications: Cross-Docking vs DSD

Cross-docking minimizes inventory holding costs by instantly transferring goods from inbound to outbound transportation, reducing warehousing needs and labor expenses. Direct Store Delivery (DSD) incurs higher transportation and handling costs as products are shipped directly to stores, often requiring more frequent deliveries and additional route management. Retailers must weigh cross-docking's efficiency-driven cost savings against DSD's higher logistics expenses but enhanced shelf availability and freshness.

Impact on Inventory Management

Cross-docking reduces inventory holding by minimizing storage time, enabling faster turnover and improved supply chain efficiency in retail operations. Direct Store Delivery (DSD) allows for real-time inventory replenishment, enhancing product availability but requiring more frequent shipments and complex coordination. Effective inventory management balances the speed of cross-docking with the responsiveness of DSD to optimize stock levels and meet consumer demand.

Effects on Supply Chain Efficiency

Cross-docking minimizes inventory holding by rapidly transferring goods from inbound to outbound transport, reducing storage costs and speeding up order fulfillment. Direct Store Delivery (DSD) enhances supply chain responsiveness by allowing manufacturers to ship products directly to retail stores, improving freshness and product availability. Both methods streamline logistics but differ in impact: cross-docking optimizes warehouse operations and reduces lead times, whereas DSD strengthens supplier-to-store communication and reduces stockouts.

Choosing the Right Method for Your Retail Business

Cross-docking streamlines retail supply chains by minimizing storage time and reducing inventory holding costs, ideal for high-volume products requiring fast turnover. Direct store delivery enhances customer service and product freshness by shipping directly from suppliers to stores, benefiting perishable goods and promotional items. Selecting the right method depends on product type, delivery frequency, and inventory management goals to optimize operational efficiency and customer satisfaction.

Future Trends in Retail Distribution Strategies

Cross-docking is evolving with automation and AI integration to enhance real-time inventory management and reduce storage costs in retail distribution. Direct Store Delivery (DSD) is increasingly leveraging IoT and last-mile delivery innovations to improve freshness and speed for perishable goods. Future trends indicate a hybrid model combining cross-docking efficiency with DSD's customer-centric approach to optimize supply chain responsiveness and cost-effectiveness.

Cross-Docking vs Direct Store Delivery Infographic

difterm.com

difterm.com