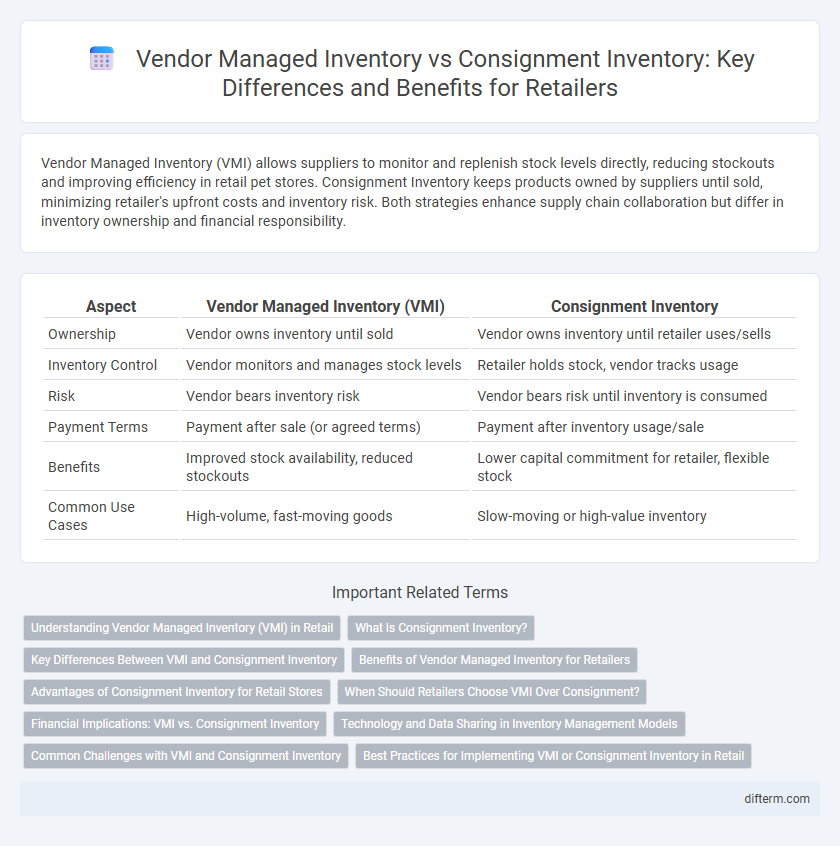

Vendor Managed Inventory (VMI) allows suppliers to monitor and replenish stock levels directly, reducing stockouts and improving efficiency in retail pet stores. Consignment Inventory keeps products owned by suppliers until sold, minimizing retailer's upfront costs and inventory risk. Both strategies enhance supply chain collaboration but differ in inventory ownership and financial responsibility.

Table of Comparison

| Aspect | Vendor Managed Inventory (VMI) | Consignment Inventory |

|---|---|---|

| Ownership | Vendor owns inventory until sold | Vendor owns inventory until retailer uses/sells |

| Inventory Control | Vendor monitors and manages stock levels | Retailer holds stock, vendor tracks usage |

| Risk | Vendor bears inventory risk | Vendor bears risk until inventory is consumed |

| Payment Terms | Payment after sale (or agreed terms) | Payment after inventory usage/sale |

| Benefits | Improved stock availability, reduced stockouts | Lower capital commitment for retailer, flexible stock |

| Common Use Cases | High-volume, fast-moving goods | Slow-moving or high-value inventory |

Understanding Vendor Managed Inventory (VMI) in Retail

Vendor Managed Inventory (VMI) in retail is a supply chain strategy where the supplier monitors and replenishes inventory based on real-time sales data, reducing stockouts and excess inventory. Retailers benefit from improved inventory turnover and lower carrying costs, while vendors gain better demand visibility and control over product availability. This collaborative approach enhances supply chain efficiency, ensuring shelves are stocked according to consumer demand without the retailer managing the inventory directly.

What Is Consignment Inventory?

Consignment inventory is a supply chain strategy where the vendor retains ownership of the stock until it is sold by the retailer, reducing the retailer's capital investment and risk. This approach improves cash flow management for retailers and encourages vendors to maintain optimal stock levels to avoid shortages. Consignment inventory is commonly used in retail sectors such as apparel, electronics, and specialty goods to streamline inventory turnover and enhance supplier-retailer collaboration.

Key Differences Between VMI and Consignment Inventory

Vendor Managed Inventory (VMI) involves suppliers managing inventory levels at the retailer's location, aiming to optimize stock based on real-time sales data, whereas Consignment Inventory places ownership of stock with the supplier until the retailer sells the product. In VMI, the retailer typically commits to a purchase agreement and is responsible for payment upon receipt, while Consignment Inventory allows retailers to hold stock without upfront payment, reducing their financial risk. Key differences include inventory ownership, risk distribution, and payment terms, with VMI emphasizing supplier-driven replenishment and Consignment focusing on shared inventory control and delayed payment.

Benefits of Vendor Managed Inventory for Retailers

Vendor Managed Inventory (VMI) enhances retail operations by reducing stockouts and overstock situations through real-time inventory monitoring and automatic replenishment by suppliers. This system lowers inventory carrying costs and improves cash flow management, allowing retailers to allocate capital more efficiently. Collaboration with vendors under VMI also streamlines supply chain processes, leading to improved order accuracy and faster response to consumer demand shifts.

Advantages of Consignment Inventory for Retail Stores

Consignment inventory allows retail stores to reduce upfront capital investment and minimize stockholding risks by only paying for goods when sold, improving cash flow management. This approach enhances inventory turnover rates and decreases obsolete stock, leading to higher operational efficiency and reduced storage costs. Retailers benefit from stronger supplier collaboration and improved product availability, ensuring better customer satisfaction and sales performance.

When Should Retailers Choose VMI Over Consignment?

Retailers should choose Vendor Managed Inventory (VMI) over Consignment Inventory when seeking improved supply chain efficiency and inventory turnover, as VMI allows vendors to monitor stock levels and replenish automatically, reducing stockouts and excess inventory. VMI is ideal for retailers with reliable vendor partnerships and data-sharing capabilities, enabling real-time visibility and collaborative forecasting to optimize stock levels. In contrast, Consignment Inventory suits situations where retailers want to minimize upfront costs and ownership risks, but VMI offers greater control and accountability for high-demand, fast-moving products.

Financial Implications: VMI vs. Consignment Inventory

Vendor Managed Inventory (VMI) reduces carrying costs for retailers by shifting inventory ownership and replenishment responsibilities to suppliers, improving cash flow and minimizing stockouts. Consignment inventory keeps ownership with the supplier until goods are sold, lowering retailer's financial risk but tying up supplier capital longer. Retailers benefit from VMI through better demand forecasting collaboration, while consignment inventory provides flexibility with minimal upfront investment but potentially higher supplier costs.

Technology and Data Sharing in Inventory Management Models

Vendor Managed Inventory (VMI) leverages real-time data sharing and advanced analytics platforms, enabling vendors to monitor stock levels directly through integrated retail systems and automate replenishment processes. Consignment Inventory relies on shared inventory visibility but typically involves more manual coordination, with retailers holding goods while payment is triggered upon sale, emphasizing data accuracy and timely reporting to optimize inventory turnover. Both models benefit from cloud-based technologies and IoT devices to enhance transparency, reduce stockouts, and streamline supply chain collaboration.

Common Challenges with VMI and Consignment Inventory

Vendor Managed Inventory (VMI) and Consignment Inventory often face challenges such as inaccurate demand forecasting, leading to stockouts or overstock situations that impact cash flow and customer satisfaction. Data sharing between retailers and suppliers can be inconsistent, resulting in misaligned inventory levels and delayed replenishments. Complexities in ownership and liability during inventory turnover create disputes and operational inefficiencies, further complicating effective inventory management.

Best Practices for Implementing VMI or Consignment Inventory in Retail

Implementing Vendor Managed Inventory (VMI) or Consignment Inventory in retail requires clear communication and robust data sharing between retailers and suppliers to ensure accurate demand forecasting and inventory replenishment. Retailers should leverage real-time inventory management systems integrated with supplier platforms to minimize stockouts and excess inventory. Regular performance reviews and defined service level agreements (SLAs) help maintain accountability and optimize supply chain efficiency.

Vendor Managed Inventory vs Consignment Inventory Infographic

difterm.com

difterm.com