Store fulfillment offers faster delivery by leveraging local inventory, reducing shipping times and enhancing customer satisfaction. Warehouse fulfillment provides greater storage capacity and centralized inventory management, allowing for bulk order processing and cost efficiency. Retailers must balance these methods to optimize order accuracy, delivery speed, and operational costs in pet product distribution.

Table of Comparison

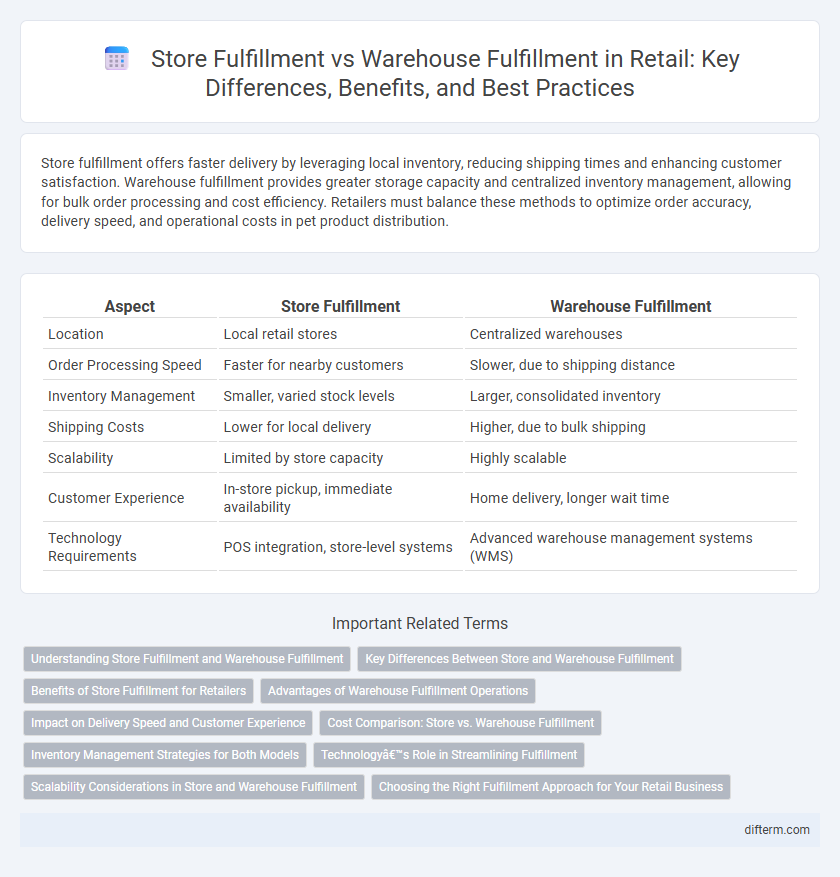

| Aspect | Store Fulfillment | Warehouse Fulfillment |

|---|---|---|

| Location | Local retail stores | Centralized warehouses |

| Order Processing Speed | Faster for nearby customers | Slower, due to shipping distance |

| Inventory Management | Smaller, varied stock levels | Larger, consolidated inventory |

| Shipping Costs | Lower for local delivery | Higher, due to bulk shipping |

| Scalability | Limited by store capacity | Highly scalable |

| Customer Experience | In-store pickup, immediate availability | Home delivery, longer wait time |

| Technology Requirements | POS integration, store-level systems | Advanced warehouse management systems (WMS) |

Understanding Store Fulfillment and Warehouse Fulfillment

Store fulfillment involves processing and shipping customer orders directly from retail locations, enabling faster delivery and local inventory utilization, while warehouse fulfillment relies on central distribution centers with larger stock volumes designed for bulk order processing. Understanding the differences is crucial for optimizing supply chain efficiency, as store fulfillment enhances same-day or next-day delivery in urban areas, whereas warehouse fulfillment supports broad geographic coverage and cost-effective inventory management. Retailers must balance these strategies to improve customer satisfaction and reduce shipping costs based on product demand and location dynamics.

Key Differences Between Store and Warehouse Fulfillment

Store fulfillment emphasizes direct consumer pick-up or same-day delivery by leveraging inventory located within individual retail locations, offering faster order processing and enhanced customer convenience. Warehouse fulfillment operates on bulk inventory stored in centralized distribution centers, optimizing large-scale order accuracy and cost-efficiency through advanced logistic systems. Key differences include proximity to customers, inventory management scale, and speed of order processing, which influence inventory allocation and delivery strategies in retail operations.

Benefits of Store Fulfillment for Retailers

Store fulfillment enhances retail agility by enabling faster order processing and same-day delivery, improving customer satisfaction. Utilizing existing retail locations reduces last-mile delivery costs and inventory holding expenses compared to traditional warehouse fulfillment. This approach also supports omni-channel strategies by seamlessly integrating in-store and online sales, leading to increased sales and optimized stock management.

Advantages of Warehouse Fulfillment Operations

Warehouse fulfillment operations offer significant advantages in retail, including centralized inventory management that enhances stock accuracy and reduces errors. Large-scale warehousing enables bulk storage and efficient order processing through automation, leading to faster turnaround times and cost savings. Additionally, specialized warehousing facilities provide better control over product handling, ensuring quality preservation and optimized logistics.

Impact on Delivery Speed and Customer Experience

Store fulfillment leverages local inventory to enable faster delivery times, significantly enhancing customer satisfaction through quicker order processing and reduced shipping distances. Warehouse fulfillment, while optimized for large-scale inventory management, often involves longer transit times that can delay delivery and affect customer experience negatively. Integrating store fulfillment with warehouse operations creates a balanced approach that improves delivery speed and meets evolving consumer expectations.

Cost Comparison: Store vs. Warehouse Fulfillment

Store fulfillment often results in lower last-mile delivery costs due to proximity to customers, reducing shipping distance and time. Warehouse fulfillment benefits from economies of scale, lowering per-unit storage and handling expenses but may incur higher transportation costs for final delivery. Optimizing the balance between store and warehouse fulfillment is essential for minimizing overall operational costs in retail distribution.

Inventory Management Strategies for Both Models

Store fulfillment relies on real-time inventory tracking within individual locations to enhance product availability and reduce stockouts, leveraging point-of-sale data integration for precise demand forecasting. Warehouse fulfillment employs centralized inventory systems that optimize bulk storage and distribution efficiency through advanced automation and replenishment algorithms. Both models benefit from synchronized inventory visibility technology that enables dynamic allocation and seamless order processing across the retail network.

Technology’s Role in Streamlining Fulfillment

Advanced technology integrates real-time inventory management and automated order processing to enhance store fulfillment by enabling faster order picking and customer-specific customization. Warehouse fulfillment benefits from robotics, AI, and predictive analytics that optimize storage layout and streamline bulk packing processes for higher accuracy and efficiency. Both models leverage interconnected systems and data analytics platforms to synchronize supply chain activities, reducing delays and ensuring timely delivery.

Scalability Considerations in Store and Warehouse Fulfillment

Store fulfillment offers scalable advantages by leveraging existing retail locations to quickly process and ship online orders, reducing last-mile delivery costs and improving customer satisfaction. Warehouse fulfillment centers provide greater scalability with specialized infrastructure, inventory management, and automation technologies designed to handle high order volumes efficiently. Balancing store and warehouse fulfillment strategies enables retailers to optimize scalability, inventory distribution, and speed of delivery in omnichannel operations.

Choosing the Right Fulfillment Approach for Your Retail Business

Store fulfillment leverages in-store inventory for faster, localized order processing, reducing delivery times and enhancing customer experience. Warehouse fulfillment centralizes inventory management, offering cost efficiency and scalability for high-volume orders but may result in longer shipping durations. Retailers should analyze order volume, geographic reach, and customer expectations to choose between store and warehouse fulfillment for optimal operational efficiency and satisfaction.

Store Fulfillment vs Warehouse Fulfillment Infographic

difterm.com

difterm.com