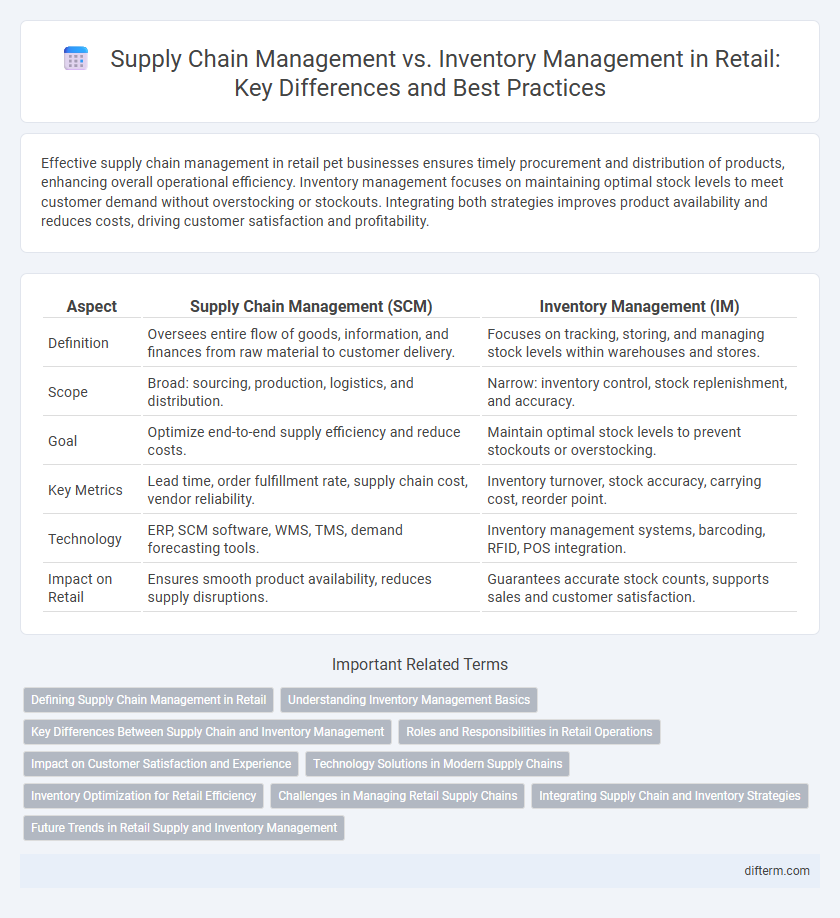

Effective supply chain management in retail pet businesses ensures timely procurement and distribution of products, enhancing overall operational efficiency. Inventory management focuses on maintaining optimal stock levels to meet customer demand without overstocking or stockouts. Integrating both strategies improves product availability and reduces costs, driving customer satisfaction and profitability.

Table of Comparison

| Aspect | Supply Chain Management (SCM) | Inventory Management (IM) |

|---|---|---|

| Definition | Oversees entire flow of goods, information, and finances from raw material to customer delivery. | Focuses on tracking, storing, and managing stock levels within warehouses and stores. |

| Scope | Broad: sourcing, production, logistics, and distribution. | Narrow: inventory control, stock replenishment, and accuracy. |

| Goal | Optimize end-to-end supply efficiency and reduce costs. | Maintain optimal stock levels to prevent stockouts or overstocking. |

| Key Metrics | Lead time, order fulfillment rate, supply chain cost, vendor reliability. | Inventory turnover, stock accuracy, carrying cost, reorder point. |

| Technology | ERP, SCM software, WMS, TMS, demand forecasting tools. | Inventory management systems, barcoding, RFID, POS integration. |

| Impact on Retail | Ensures smooth product availability, reduces supply disruptions. | Guarantees accurate stock counts, supports sales and customer satisfaction. |

Defining Supply Chain Management in Retail

Supply Chain Management in retail involves overseeing the entire flow of goods from suppliers to customers, ensuring efficient procurement, production, and distribution processes. It integrates demand forecasting, supplier coordination, logistics, and inventory control to optimize product availability and reduce costs. Effective supply chain management enhances retail operations by improving delivery speed, minimizing stockouts, and increasing customer satisfaction.

Understanding Inventory Management Basics

Inventory Management involves tracking, ordering, and storing products to meet customer demand efficiently within the supply chain. It focuses on maintaining optimal stock levels, reducing carrying costs, and preventing stockouts or overstock situations. Effective inventory management requires accurate demand forecasting, real-time monitoring, and seamless coordination with suppliers and logistics to ensure product availability in retail operations.

Key Differences Between Supply Chain and Inventory Management

Supply chain management encompasses the entire flow of goods, services, and information from raw material sourcing to product delivery, optimizing processes across multiple stakeholders. Inventory management specifically focuses on controlling stock levels, tracking inventory turnover, and managing reorder points within warehouses and retail locations. The key difference lies in supply chain management's broad scope of coordination and logistics, while inventory management zeroes in on maintaining optimal stock availability to meet customer demand.

Roles and Responsibilities in Retail Operations

Supply Chain Management in retail coordinates the end-to-end flow of goods, from supplier sourcing to product delivery, ensuring demand forecasting, procurement, logistics, and supplier relationship management are optimized. Inventory Management focuses on controlling stock levels, tracking product availability, preventing stockouts or overstock situations, and managing warehouse operations to maintain an efficient inventory turnover rate. Together, these functions enhance retail operational efficiency by balancing supply continuity with inventory accuracy and cost control.

Impact on Customer Satisfaction and Experience

Effective supply chain management ensures timely product availability and reduces stockouts, directly enhancing customer satisfaction by meeting demand consistently. Inventory management optimizes stock levels, preventing overstock or shortages, which improves the shopping experience through product reliability. Together, these functions streamline operations to deliver seamless service, positively influencing customer loyalty in retail.

Technology Solutions in Modern Supply Chains

Advanced technology solutions like AI-powered demand forecasting and blockchain-enabled traceability significantly enhance both supply chain management and inventory management in retail. Supply chain management leverages integrated platforms for real-time visibility and coordination across suppliers, logistics, and distribution channels, optimizing end-to-end processes. Inventory management uses automated systems and IoT sensors to monitor stock levels accurately, reduce shrinkage, and improve replenishment efficiency, ensuring seamless product availability.

Inventory Optimization for Retail Efficiency

Inventory optimization in retail involves balancing stock levels to meet customer demand while minimizing holding costs, directly enhancing supply chain efficiency. Advanced analytics and demand forecasting tools enable retailers to reduce stockouts and overstock situations, leading to improved turnover rates and cash flow. Integrating inventory management with supply chain processes ensures synchronized replenishment and distribution, maximizing overall operational performance.

Challenges in Managing Retail Supply Chains

Managing retail supply chains involves complex challenges such as demand variability, supplier reliability, and lead time uncertainties, which directly impact inventory accuracy and product availability. Retailers face difficulties in coordinating multiple suppliers and distribution centers while optimizing stock levels to avoid both overstock and stockouts. Integrating advanced forecasting tools and real-time data analytics enhances visibility across the supply chain, mitigating risks related to disruptions and improving overall inventory management efficiency.

Integrating Supply Chain and Inventory Strategies

Integrating supply chain and inventory strategies enhances retail efficiency by aligning procurement, warehousing, and distribution processes with real-time inventory data, reducing stockouts and overstock situations. A unified approach leverages predictive analytics and demand forecasting to optimize reorder points and improve supplier collaboration, ultimately driving cost savings and faster response times. Retailers gain competitive advantage by synchronizing supply chain visibility with inventory control, ensuring seamless product availability and improved customer satisfaction.

Future Trends in Retail Supply and Inventory Management

Artificial intelligence and machine learning are transforming retail supply chain and inventory management by enabling predictive analytics for demand forecasting and real-time inventory optimization. Blockchain technology enhances transparency and traceability across supply chains, reducing fraud and improving supplier collaboration. Automation through robotics and IoT devices streamlines warehouse operations, ensuring faster replenishment and minimizing stockouts in future retail environments.

Supply Chain Management vs Inventory Management Infographic

difterm.com

difterm.com