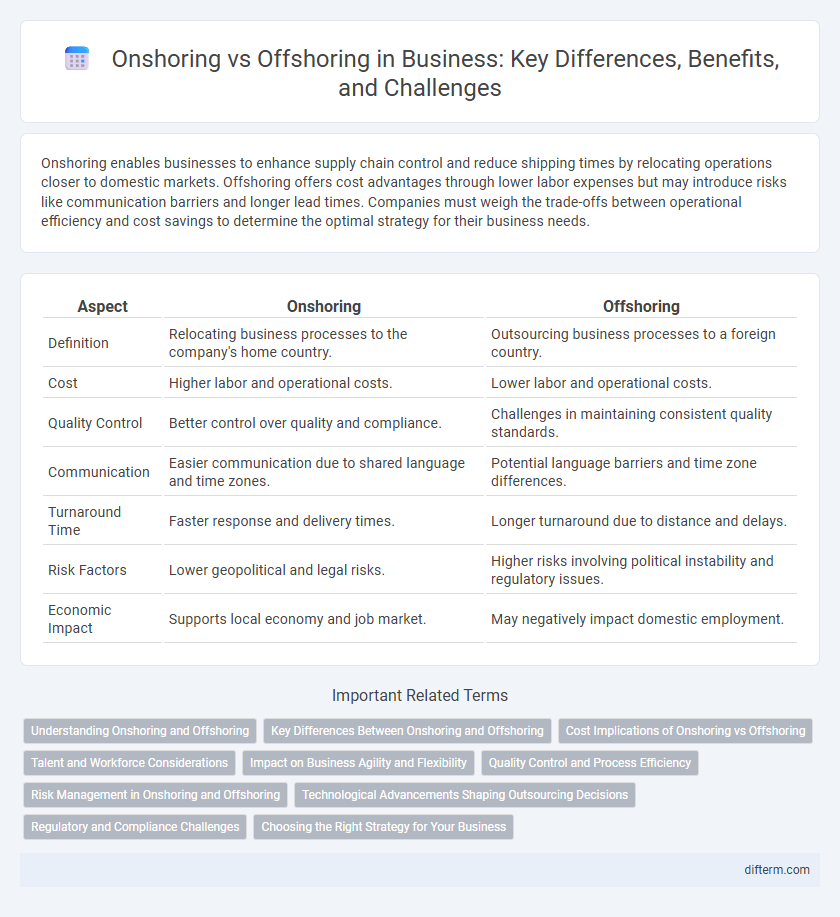

Onshoring enables businesses to enhance supply chain control and reduce shipping times by relocating operations closer to domestic markets. Offshoring offers cost advantages through lower labor expenses but may introduce risks like communication barriers and longer lead times. Companies must weigh the trade-offs between operational efficiency and cost savings to determine the optimal strategy for their business needs.

Table of Comparison

| Aspect | Onshoring | Offshoring |

|---|---|---|

| Definition | Relocating business processes to the company's home country. | Outsourcing business processes to a foreign country. |

| Cost | Higher labor and operational costs. | Lower labor and operational costs. |

| Quality Control | Better control over quality and compliance. | Challenges in maintaining consistent quality standards. |

| Communication | Easier communication due to shared language and time zones. | Potential language barriers and time zone differences. |

| Turnaround Time | Faster response and delivery times. | Longer turnaround due to distance and delays. |

| Risk Factors | Lower geopolitical and legal risks. | Higher risks involving political instability and regulatory issues. |

| Economic Impact | Supports local economy and job market. | May negatively impact domestic employment. |

Understanding Onshoring and Offshoring

Onshoring involves relocating business operations to the company's home country, boosting local employment and simplifying regulatory compliance. Offshoring transfers processes to foreign countries, often to leverage lower labor costs and access specialized skills. Understanding these strategies helps businesses balance cost efficiency, quality control, and market responsiveness.

Key Differences Between Onshoring and Offshoring

Onshoring involves relocating business processes to the company's home country, enhancing control, communication, and compliance with local regulations. Offshoring shifts operations to foreign countries, primarily driven by cost reduction and access to specialized talent pools. Key differences between onshoring and offshoring include differences in operational costs, proximity to core markets, and the complexity of managing international regulations.

Cost Implications of Onshoring vs Offshoring

Onshoring typically involves higher upfront labor costs compared to offshoring due to wage differences in domestic markets. However, onshoring reduces expenses related to logistics, tariffs, and communication, which can offset initial labor cost advantages of offshoring. Companies must analyze total cost of ownership, including quality control and supply chain risks, to determine the most financially viable strategy.

Talent and Workforce Considerations

Onshoring provides businesses access to a domestic talent pool with localized expertise, reducing language barriers and cultural misalignments often encountered in offshoring. Workforce considerations include evaluating the availability of skilled professionals, labor costs, and employee retention rates, which tend to be higher in onshore markets due to improved working conditions and regulatory protections. Offshoring may offer cost advantages but often involves challenges related to talent quality, time zone disparities, and higher turnover rates that can impact project continuity.

Impact on Business Agility and Flexibility

Onshoring enhances business agility by enabling faster response times and closer collaboration with local teams, reducing communication barriers and logistical delays. Offshoring can increase operational flexibility through cost savings and access to global talent, but may introduce risks such as time zone differences and cultural misunderstandings that slow decision-making. Companies must balance these factors to optimize agility and maintain competitive responsiveness in dynamic markets.

Quality Control and Process Efficiency

Onshoring enhances quality control by enabling closer oversight and faster response times to defects, reducing production errors and improving product consistency. Process efficiency benefits from streamlined communication and integrated teams, minimizing delays caused by time zone differences and cultural misunderstandings common in offshoring. Companies shifting production onshore often experience improved alignment with quality standards and operational workflows.

Risk Management in Onshoring and Offshoring

Onshoring reduces supply chain disruptions and geopolitical risks by keeping operations closer to the home market, enhancing control over compliance and quality standards. Offshoring exposes businesses to greater risks such as political instability, currency fluctuations, and communication barriers that can compromise project timelines and increase costs. Effective risk management in offshoring requires robust vendor due diligence, diversified supplier bases, and agile contingency planning to mitigate potential operational setbacks.

Technological Advancements Shaping Outsourcing Decisions

Technological advancements such as artificial intelligence, automation, and cloud computing have significantly influenced outsourcing decisions by enhancing onshoring capabilities through increased efficiency and real-time collaboration. Businesses leverage these technologies to reduce dependency on distant offshore teams, minimize communication delays, and improve quality control within local markets. Investment in advanced digital infrastructure enables firms to optimize operational costs while maintaining agility in supply chain management and product development.

Regulatory and Compliance Challenges

Onshoring reduces regulatory and compliance challenges by aligning operations with domestic laws and standards, minimizing risks associated with foreign legal environments. Offshoring often introduces complex compliance issues due to differing international regulations, including data privacy, labor laws, and intellectual property protections. Companies must invest in robust legal expertise and monitoring systems to navigate these challenges effectively in offshored locations.

Choosing the Right Strategy for Your Business

Selecting the optimal strategy between onshoring and offshoring depends on factors like cost efficiency, quality control, and supply chain reliability. Onshoring offers enhanced oversight, faster turnaround, and supports local economies, while offshoring provides significant labor cost savings and access to specialized skills. Businesses must evaluate their priorities regarding proximity, regulatory compliance, and market responsiveness to determine which approach aligns best with their operational goals.

onshoring vs offshoring Infographic

difterm.com

difterm.com