Variable Valve Timing enhances engine performance and fuel efficiency by adjusting the timing of valve operation according to driving conditions, unlike Fixed Timing which operates with a constant valve schedule. This technology optimizes power output and reduces emissions, providing a smoother driving experience and better fuel economy. Fixed Timing may offer simplicity and reliability but lacks the adaptability that Variable Valve Timing delivers for modern automotive engines.

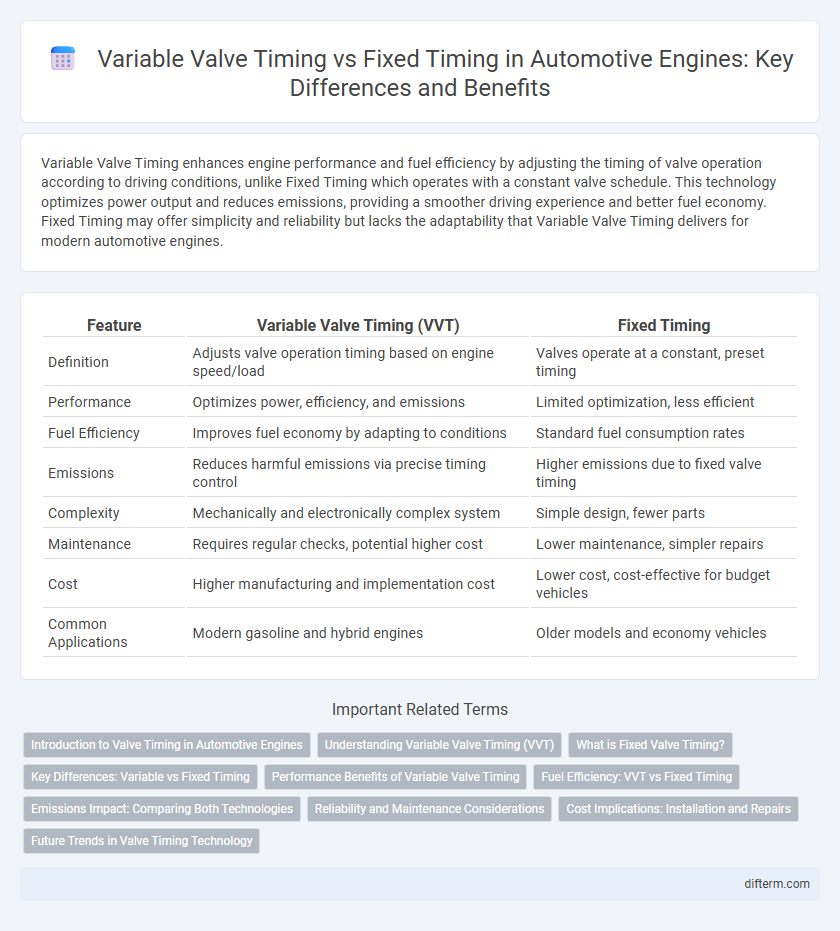

Table of Comparison

| Feature | Variable Valve Timing (VVT) | Fixed Timing |

|---|---|---|

| Definition | Adjusts valve operation timing based on engine speed/load | Valves operate at a constant, preset timing |

| Performance | Optimizes power, efficiency, and emissions | Limited optimization, less efficient |

| Fuel Efficiency | Improves fuel economy by adapting to conditions | Standard fuel consumption rates |

| Emissions | Reduces harmful emissions via precise timing control | Higher emissions due to fixed valve timing |

| Complexity | Mechanically and electronically complex system | Simple design, fewer parts |

| Maintenance | Requires regular checks, potential higher cost | Lower maintenance, simpler repairs |

| Cost | Higher manufacturing and implementation cost | Lower cost, cost-effective for budget vehicles |

| Common Applications | Modern gasoline and hybrid engines | Older models and economy vehicles |

Introduction to Valve Timing in Automotive Engines

Variable valve timing (VVT) enhances engine performance by adjusting the timing of valve lift events based on operating conditions, improving fuel efficiency and reducing emissions compared to fixed valve timing systems. Fixed valve timing maintains a constant valve opening and closing schedule, which limits engine optimization across varying speeds and loads. Advances in automotive engineering prioritize VVT for its ability to optimize air-fuel mixture intake and exhaust gas expulsion, resulting in better power output and lower environmental impact.

Understanding Variable Valve Timing (VVT)

Variable Valve Timing (VVT) dynamically adjusts the timing of valve opening and closing to optimize engine performance, fuel efficiency, and emissions. Unlike Fixed Timing systems, which operate at a constant valve schedule regardless of engine speed or load, VVT uses sensors and actuators to modify valve events based on real-time driving conditions. This technology improves torque output across the RPM range and reduces exhaust emissions by enhancing combustion efficiency.

What is Fixed Valve Timing?

Fixed valve timing refers to a traditional engine valve system where the opening and closing of intake and exhaust valves occur at predetermined, unchanging intervals throughout engine operation. This setup lacks adaptability to engine speed or load variations, which can limit fuel efficiency and performance compared to modern variable valve timing systems. Fixed timing designs often result in a compromise between low-end torque and high-end power, affecting overall engine responsiveness and emissions control.

Key Differences: Variable vs Fixed Timing

Variable Valve Timing (VVT) adjusts the timing of valve opening and closing dynamically based on engine speed and load, improving fuel efficiency, power output, and emissions control. Fixed timing uses a constant valve operation schedule, limiting optimization to specific engine conditions and often resulting in lower performance across variable speeds. Key differences include VVT's ability to enhance engine flexibility and responsiveness, whereas fixed timing offers simplicity and reduced mechanical complexity.

Performance Benefits of Variable Valve Timing

Variable Valve Timing (VVT) enhances engine performance by dynamically adjusting the timing of valve opening and closing based on driving conditions, resulting in improved horsepower and torque across a wider RPM range compared to fixed timing systems. VVT optimizes air-fuel mixture intake and exhaust gas expulsion, increasing fuel efficiency and reducing emissions while maintaining engine responsiveness. Fixed timing systems, in contrast, are limited by a predetermined valve timing, which restricts engine adaptability and overall performance optimization.

Fuel Efficiency: VVT vs Fixed Timing

Variable Valve Timing (VVT) dynamically adjusts the timing of valve opening and closing based on engine speed and load, significantly improving fuel efficiency by optimizing air-fuel mixture intake and combustion. Fixed Timing systems operate with a constant valve timing, often leading to less efficient fuel consumption under varying driving conditions. Advanced VVT technologies, such as continuously variable systems, can enhance fuel economy by up to 10-15% compared to traditional fixed timing setups.

Emissions Impact: Comparing Both Technologies

Variable Valve Timing (VVT) significantly reduces emissions by optimizing valve operation based on engine load and speed, improving combustion efficiency and lowering NOx, CO, and HC emissions. Fixed timing systems, with static valve operation, cannot respond to varying engine conditions, leading to higher pollutant output and less efficient fuel combustion. VVT technology supports compliance with stricter emission regulations by enhancing engine performance while minimizing environmental impact.

Reliability and Maintenance Considerations

Variable Valve Timing (VVT) systems enhance engine efficiency and performance by dynamically adjusting valve operation but may introduce complexity, potentially increasing maintenance frequency and repair costs compared to fixed timing setups. Fixed timing mechanisms offer simplicity and proven reliability with lower maintenance demands due to fewer moving parts and less electronic control involvement. Evaluating the trade-off between advanced performance benefits and long-term reliability is crucial for automotive owners prioritizing lower maintenance efforts.

Cost Implications: Installation and Repairs

Variable valve timing (VVT) systems typically incur higher installation costs due to their complex components and precision engineering compared to fixed timing setups. Repair expenses for VVT systems are generally greater, as they require specialized diagnostics and parts, while fixed timing mechanisms are simpler and more cost-effective to maintain. The long-term cost savings with VVT come from improved fuel efficiency and reduced emissions, which can offset initial higher service charges.

Future Trends in Valve Timing Technology

Variable valve timing (VVT) systems are expected to evolve with integration of advanced electronic control units and artificial intelligence to optimize engine efficiency and emissions dynamically across diverse driving conditions. Future trends indicate a shift towards fully adjustable cam profiles and electromagnetic actuators, enabling faster response times and greater precision compared to traditional fixed timing mechanisms. These innovations aim to enhance fuel economy and reduce carbon footprints while supporting the transition to hybrid and alternative fuel powertrains.

Variable Valve Timing vs Fixed Timing Infographic

difterm.com

difterm.com