OBD-I and OBD-II are automotive diagnostic systems designed to monitor vehicle performance and emissions, with OBD-II providing more comprehensive data and standardized protocols across all makes and models post-1996. While OBD-I systems vary by manufacturer and offer limited diagnostic capabilities, OBD-II includes a universal 16-pin connector and supports advanced features such as real-time data streaming and enhanced troubleshooting. Transitioning to OBD-II improves accuracy in detecting engine issues, emission control, and facilitating repairs through standardized codes and interfaces.

Table of Comparison

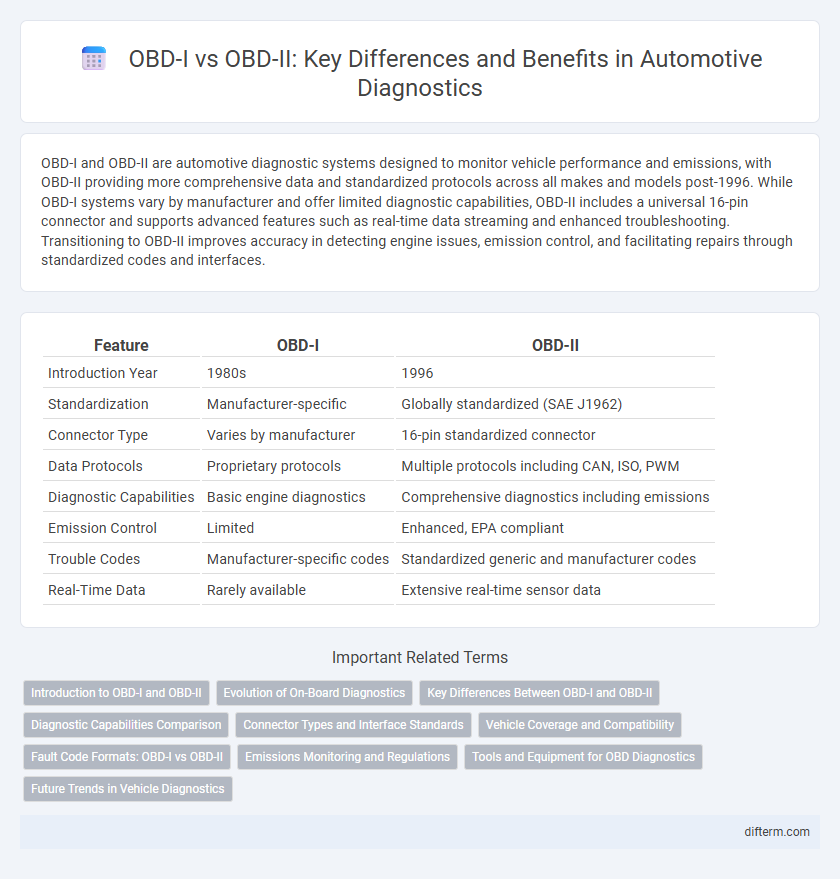

| Feature | OBD-I | OBD-II |

|---|---|---|

| Introduction Year | 1980s | 1996 |

| Standardization | Manufacturer-specific | Globally standardized (SAE J1962) |

| Connector Type | Varies by manufacturer | 16-pin standardized connector |

| Data Protocols | Proprietary protocols | Multiple protocols including CAN, ISO, PWM |

| Diagnostic Capabilities | Basic engine diagnostics | Comprehensive diagnostics including emissions |

| Emission Control | Limited | Enhanced, EPA compliant |

| Trouble Codes | Manufacturer-specific codes | Standardized generic and manufacturer codes |

| Real-Time Data | Rarely available | Extensive real-time sensor data |

Introduction to OBD-I and OBD-II

OBD-I (On-Board Diagnostics I) was the initial standardized system introduced in the early 1980s to monitor vehicle engine performance and emissions, offering limited diagnostic capabilities with manufacturer-specific protocols. OBD-II, mandated in all U.S. cars manufactured after 1996, provides a more advanced and universal diagnostic system with standardized trouble codes and improved real-time data access to enhance emission control and vehicle maintenance. The transition from OBD-I to OBD-II marked a significant advancement in automotive diagnostics, enabling technicians and vehicle owners to more effectively identify and resolve issues related to engine and emissions systems.

Evolution of On-Board Diagnostics

On-Board Diagnostics evolved significantly from OBD-I to OBD-II, with OBD-II introducing standardized diagnostic trouble codes (DTCs) and real-time data monitoring that improved vehicle maintenance and emissions control. OBD-I systems were manufacturer-specific and limited in scope, mainly focusing on basic engine parameters. The transition to OBD-II established a universal 16-pin connector and enhanced communication protocols, enabling comprehensive diagnostics across all vehicle systems to meet stricter regulatory standards.

Key Differences Between OBD-I and OBD-II

OBD-I systems primarily provide limited, manufacturer-specific diagnostic codes and lacked standardized connectors, whereas OBD-II features universal connectors and a standardized set of diagnostic trouble codes (DTCs) that cover a wide range of vehicle systems. OBD-II monitors emissions-related components more comprehensively, including real-time data and readiness status, enhancing vehicle emissions control and repair accuracy. The transition from OBD-I to OBD-II in the mid-1990s marked a significant improvement in diagnostic capabilities, regulatory compliance, and interoperability across different vehicle makes and models.

Diagnostic Capabilities Comparison

OBD-I systems provide limited diagnostic capabilities, primarily offering basic engine codes and requiring manual interpretation, whereas OBD-II delivers comprehensive real-time data, standardized trouble codes, and enhanced monitoring of emissions-related components. OBD-II supports extensive diagnostics, including data from sensors, emission controls, and powertrain systems, facilitating precise fault detection and repair. The shift from OBD-I to OBD-II significantly improves vehicle diagnostics accuracy and emissions compliance for modern automotive maintenance.

Connector Types and Interface Standards

OBD-I connectors typically feature a variety of manufacturer-specific 12-pin or 16-pin configurations, lacking a standardized interface, which complicates diagnostics across different car brands. OBD-II connectors universally use a 16-pin (J1962) interface standardized by the SAE J1962 specification, enabling uniform access for diagnostic tools. The OBD-II system also adheres to multiple communication protocols like ISO 9141, ISO 14230 (KWP2000), and ISO 15765 (CAN), ensuring compatibility across vehicles manufactured after 1996.

Vehicle Coverage and Compatibility

OBD-I systems, introduced in the early 1980s, offer limited vehicle coverage and are primarily compatible with models produced before 1996, varying significantly between manufacturers. In contrast, OBD-II, standardized in 1996, provides extensive compatibility across nearly all gasoline-fueled vehicles and light trucks sold in the United States, covering a broader range of diagnostics and emissions data. This universal standard enables consistent vehicle coverage and interoperability with various diagnostic tools across multiple car brands.

Fault Code Formats: OBD-I vs OBD-II

OBD-I fault code formats consist of manufacturer-specific codes that vary widely, lacking standardization and making diagnostics challenging across different vehicle brands. In contrast, OBD-II employs a standardized five-character alphanumeric code system, beginning with a letter followed by four digits, categorizing faults into generic (P0xxx) and manufacturer-specific (P1xxx) codes. This uniformity in OBD-II fault codes streamlines diagnostic processes, enabling accurate identification and troubleshooting of engine and emissions-related issues across all compliant vehicles.

Emissions Monitoring and Regulations

OBD-II offers more comprehensive emissions monitoring than OBD-I, featuring standardized diagnostics across all vehicles manufactured since 1996, ensuring compliance with stricter EPA and CARB regulations. It monitors a wider range of emission control systems, including catalysts, oxygen sensors, and evaporative emissions, providing precise fault codes for early detection and efficient repair. This enhanced regulatory framework significantly reduces pollutants, supporting cleaner air standards compared to the less rigorous OBD-I system.

Tools and Equipment for OBD Diagnostics

OBD-II diagnostic tools offer enhanced compatibility with a wider range of vehicle makes and models compared to OBD-I systems, providing standardized connectors and protocols for efficient data retrieval. OBD-II scanners feature advanced functionalities such as real-time data streaming, freeze frame analysis, and enhanced trouble code reading, which are often absent in OBD-I diagnostic equipment. Investments in OBD-II compatible scan tools ensure comprehensive vehicle diagnostics, faster troubleshooting, and improved accuracy in identifying engine and emission-related issues.

Future Trends in Vehicle Diagnostics

OBD-II systems have become the global standard for vehicle diagnostics, offering enhanced data access, real-time monitoring, and standardized trouble codes compared to the limited capabilities of OBD-I. Future trends in vehicle diagnostics emphasize integrating AI-driven predictive analytics, cloud connectivity for remote monitoring, and advanced sensor fusion to improve accuracy and early fault detection. The evolution towards autonomous and electric vehicles will also demand more sophisticated diagnostic protocols and cybersecurity measures within OBD frameworks.

OBD-I vs OBD-II Infographic

difterm.com

difterm.com